High wear-resistant valve pressurizing oil seal

A highly wear-resistant, valve technology, applied in lift valves, engine components, machines/engines, etc., can solve the problems of engine turbocharged sealing performance decline, aggravation of other parts loss, wear of sealing lip and other problems, so that it is not easy to wear , Eliminate potential safety hazards, ensure normal work and the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

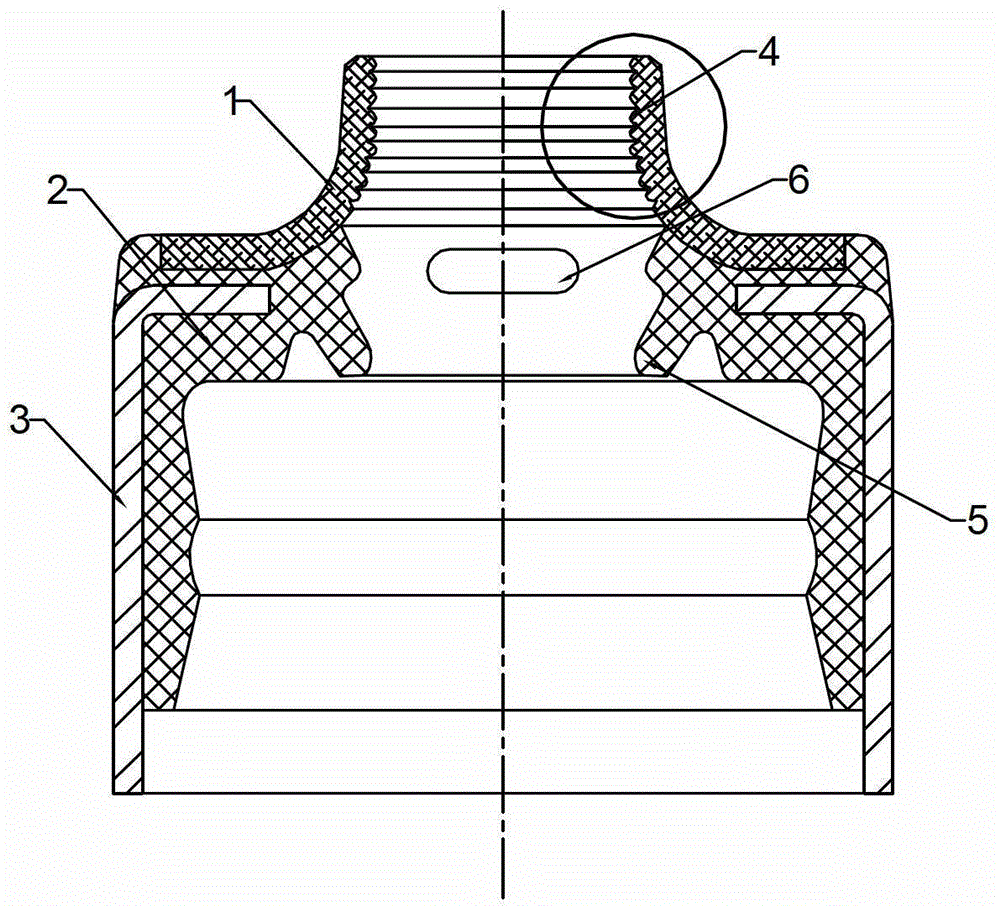

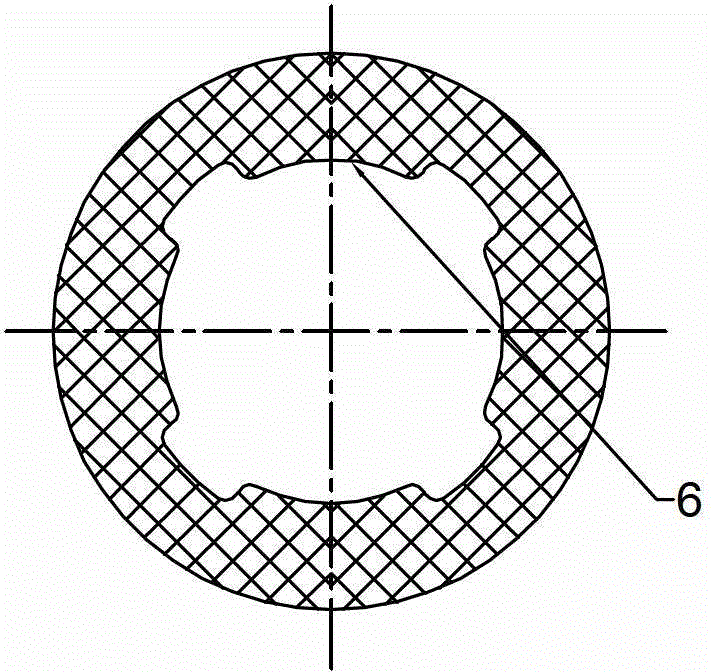

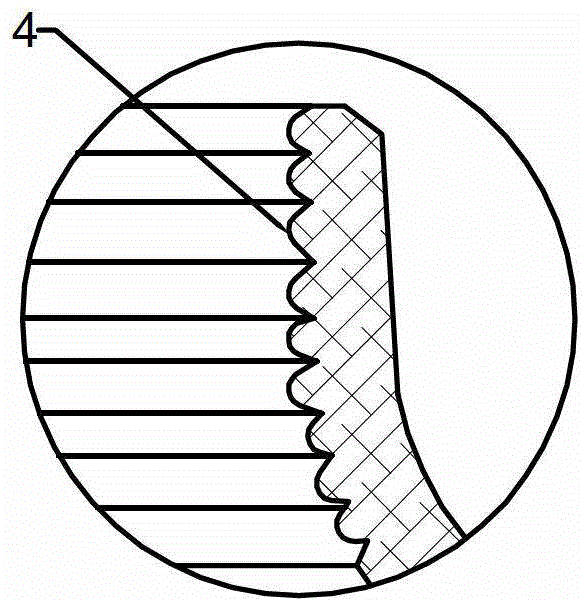

[0012] Such as figure 1 As shown, in this embodiment, the PTFE patch 1, the rubber body 2, and the skeleton 3 are vulcanized and bonded by a mold. After molding, a main lip 4 that is interference-fitted with the valve stem 8 is formed on the PTFE patch 1. The main lip 4 is in a ring-shaped sawtooth shape. On the rubber body 2, a back pressure air lip 5 with an interference fit with the valve stem 8 and 4 bosses 6 with a clearance fit with the valve stem 8 are formed. The bosses 6 are divided into 4 equal parts. Evenly distributed, the gap between the valve stem 8 is 0.1-0.2mm, the boss 6 is located between the back pressure air lip 5 and the main lip 4, and the distance between two adjacent bosses 6 is less than or equal to 1 / 2 The length of the boss 6.

[0013] Such as Figure 4 As shown, after the assembly of the present embodiment, the main lip 4 and the valve stem form 8 form a multi-lip interference fit. Since the main lip 4 is made of PTFE material, it has anti-wear ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com