Rolling bearing unit with combination seal ring

A combined sealing and rolling bearing technology, used in rolling contact bearings, bearing components, bearings in rotating motion, etc., can solve the problems of reduced interference, inability to shorten the overall length, and small thickness and size, and achieve the purpose of suppressing the increase of sliding torque, The effect of preventing the reduction of life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

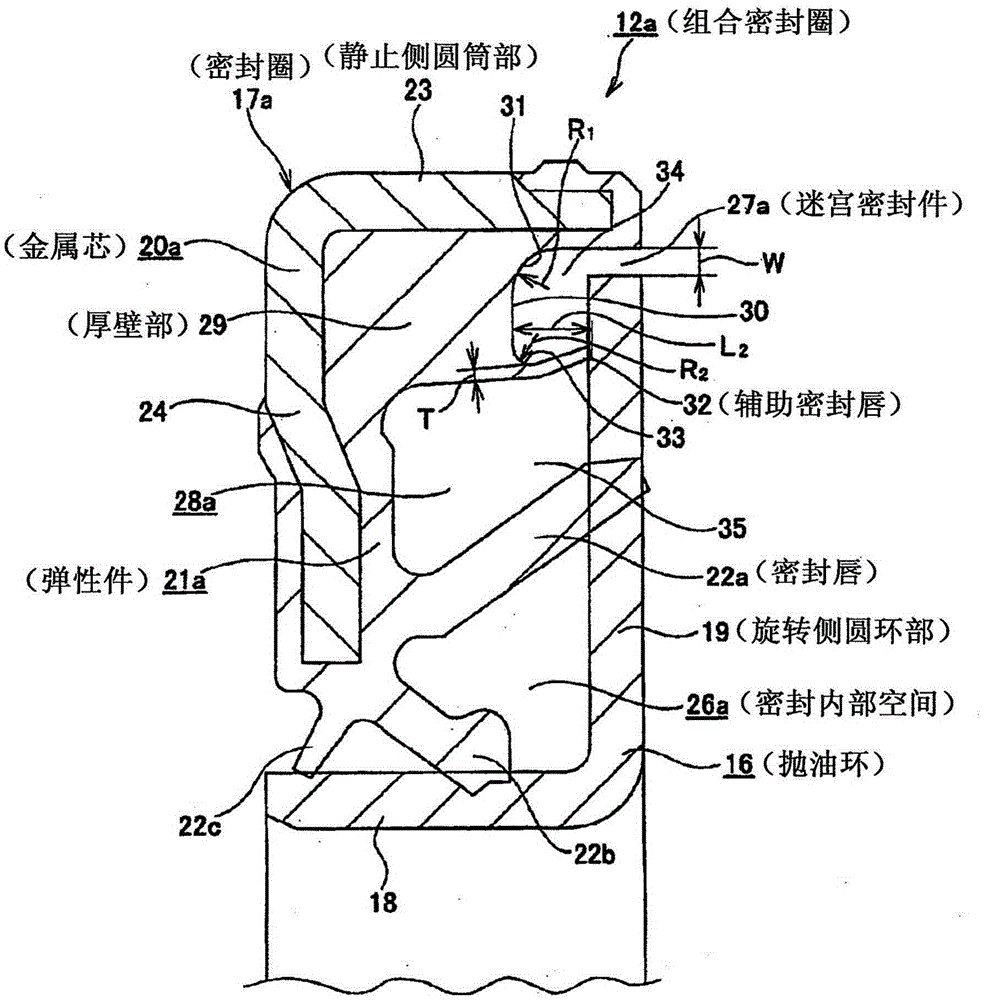

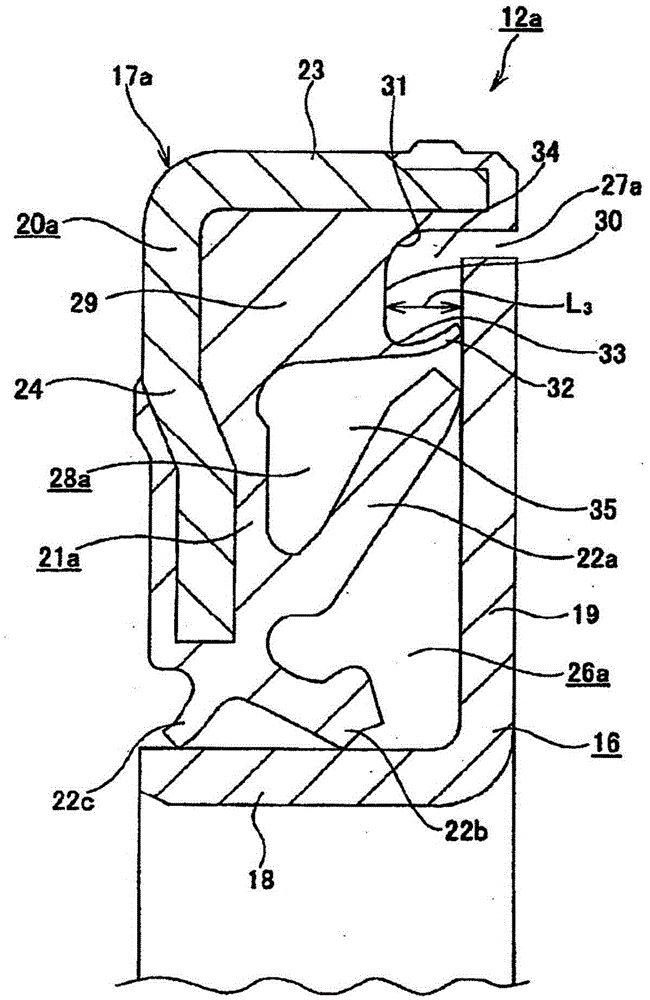

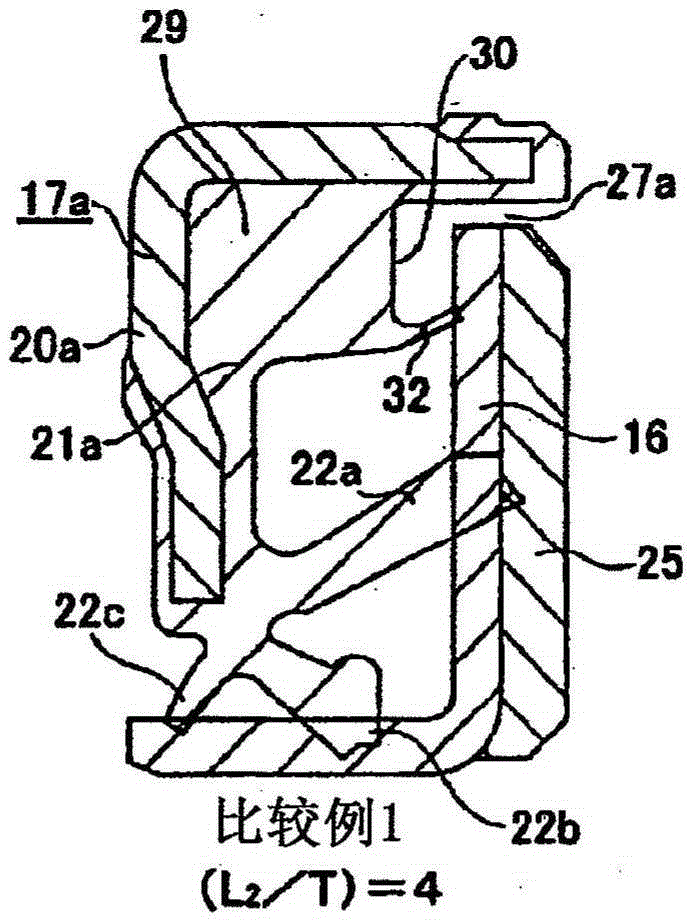

[0133] Next, experiments conducted to confirm the effects of the present invention will be described. In this experiment, the purpose of investigating the relationship between the axial full length and the thickness dimension of the auxiliary sealing lip 32 in a free state (L 2 / T), and the size of the interference of the auxiliary sealing lip 32 on the life of the combined sealing ring and the influence of the torque. When carrying out this experiment, the outer diameter is 75mm, the inner diameter is 61mm, the assembly width is 5mm, and the encoder 25 is attached and supported on the axial inner surface of the oil flinger 16. Figure 3A-3E Sample of 5 combined seals shown. Figure 3B , 3C Examples 1 and 2 show that the full axial length of the auxiliary seal lip 32 in a free state is within the range of 5.5 to 7.5 times the thickness dimension. Wherein embodiment 1 (L 2 / T) value is 5.5 times, embodiment 2 (L 2 / T) is 7.5 times. In contrast, Figure 3A , 3D Comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com