Method for preventing looseness of ceramic contact pin and metal body fit

A metal body and pin technology, which is applied to the coupling of optical waveguides and other directions, can solve the problems of reduced interference fit force, loose fit between ceramic pins and metal bodies, and loose fit, and achieves high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

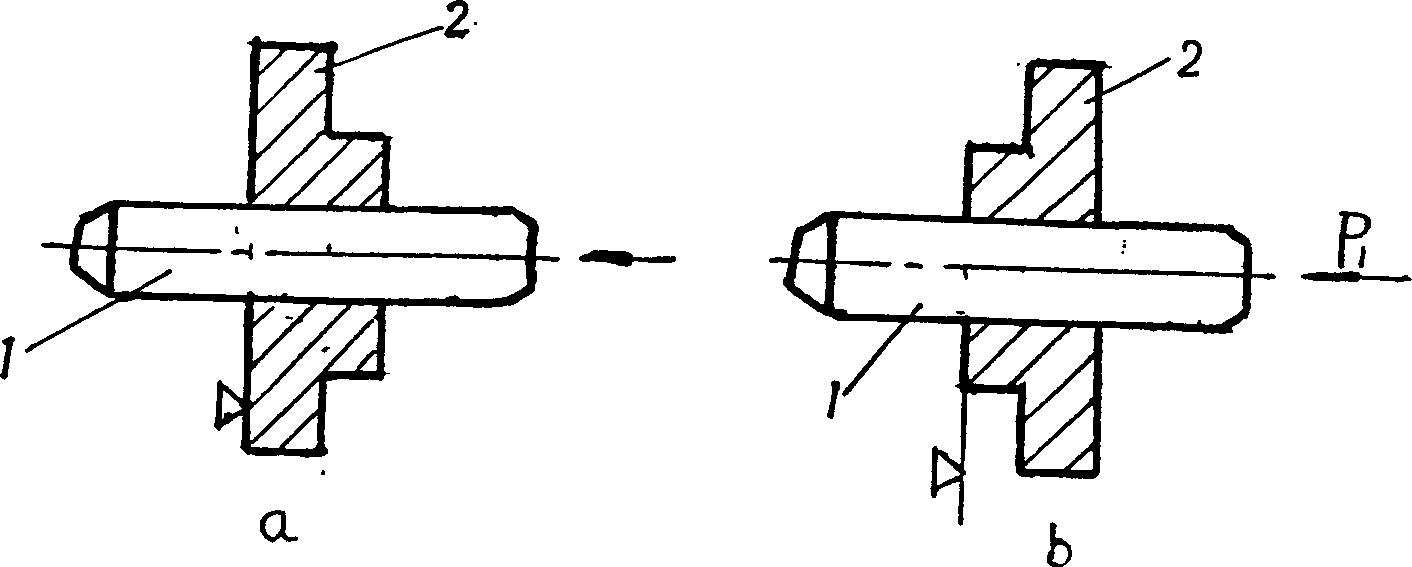

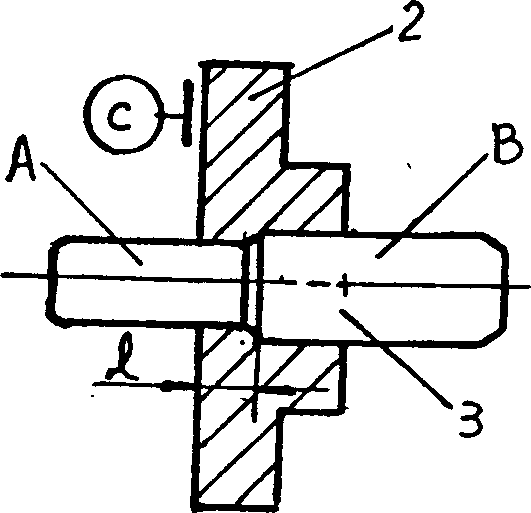

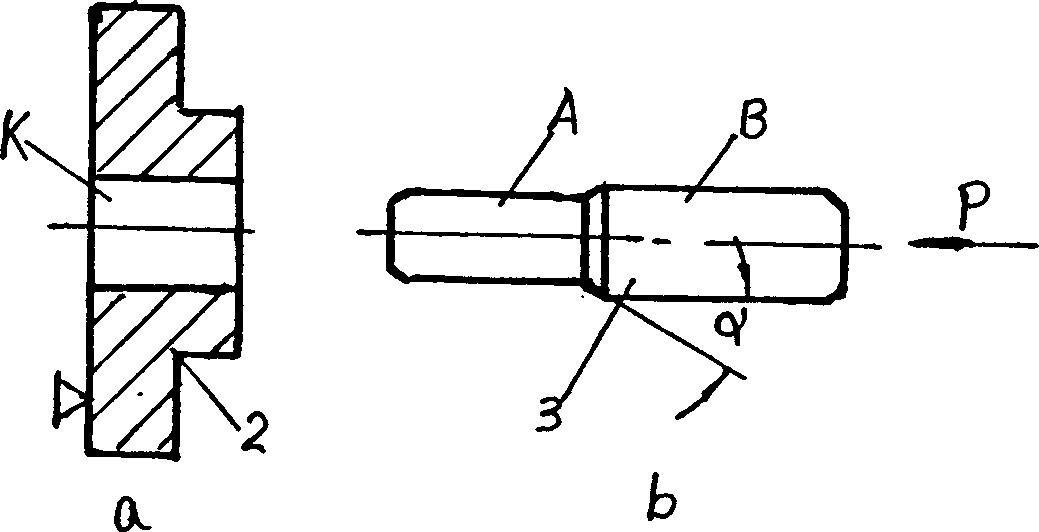

[0018] Embodiment 1 (see Figure 4 )

[0019] A mating assembly of a ceramic pin 3 and a nickel-chromium alloy pin body 2, the diameter of section A of the thin shaft section of the ceramic pin 3 is φ2.5-0.02~-0.07mm, and the diameter of section B of the thick shaft section is φ2.499±0.0005mm, The nickel-chromium alloy pin body 2 has a hole diameter of φ2.5±0.008~-0.014mm. In practical applications, the ceramic pin bears a pressure of 10kg. Whether it is at room temperature or after a low-high temperature cycle test, the ceramic pin is The displacement of the body does not move at all.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com