PTFE (polytetrafluoroethylene) oil seal of multi-group oil return lines

A technology of oil return line and oil seal, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor sealing performance, deterioration of lubricating oil, large width, spacing, and depth of spiral oil return groove, and achieve good sealing performance , taking into account the effect of sealing and wear resistance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

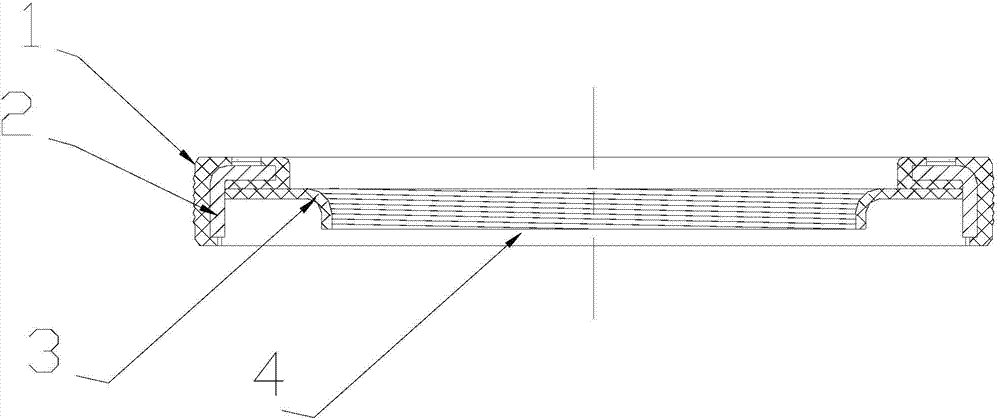

[0032] refer to figure 1 A PTFE multi-group oil return line oil seal shown includes a rubber material 1, a skeleton 2, a sealing lip 3 made of PTFE material, and an oil return line 4 arranged on the sealing lip 3.

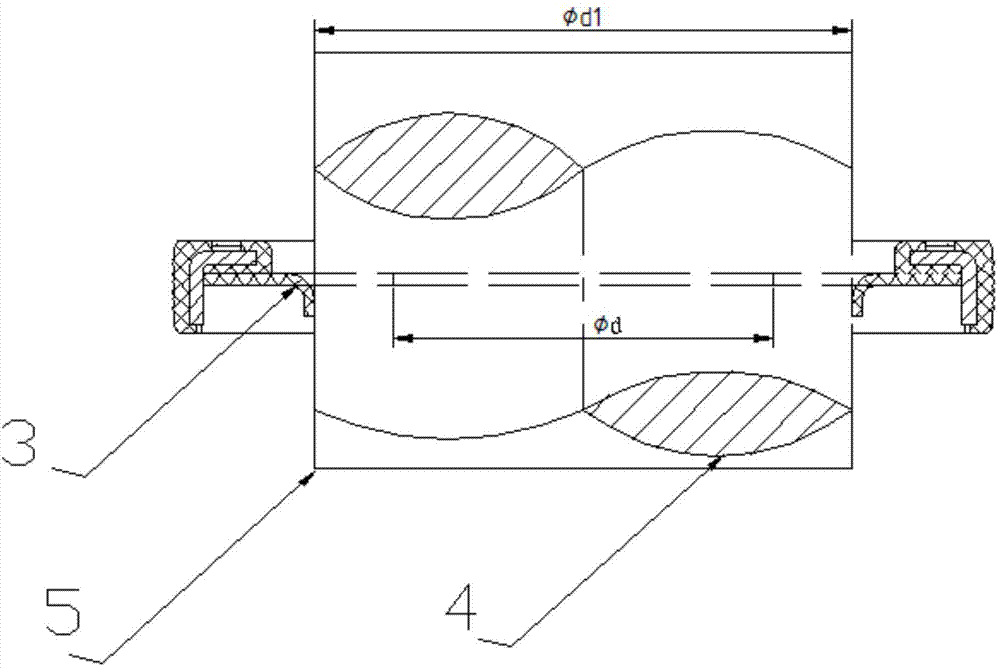

[0033] refer to figure 2 As shown, the sealing lip 3 seals the rotating shaft 5, and the oil return line 4 wraps the rotating shaft 5 from the outside. The diameter difference between the diameter Φd1 of the rotating shaft 5 and the diameter Φd of the inner hole of the sealing lip 3 is Φd1-Φd=6mm .

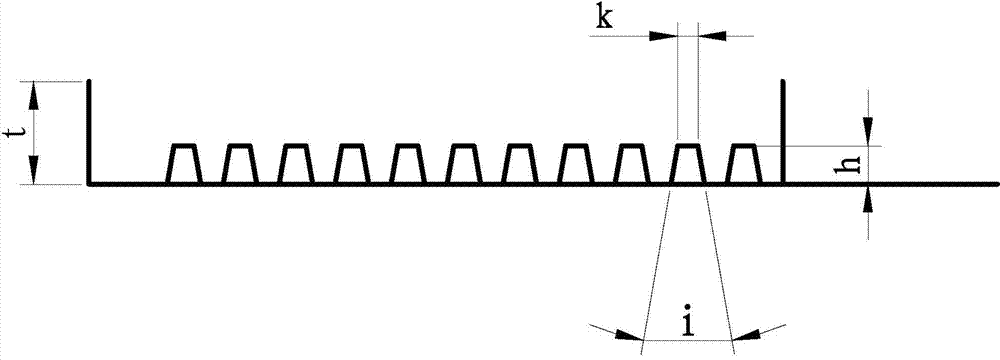

[0034] refer to image 3 As shown, the depth of the oil return line groove is h=0.2mm, the angle between the two sides of the groove is 20°, and the thickness of the PTFE sealing lip 4 is t=0.5mm.

[0035] refer to Figure 4 As shown, the double-ended oil return lines are two groups of oil return lines arranged symmetrically at 180°, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com