Rear axle main speed reducer and sleeve assembly assembling equipment and assembling process thereof

A main reducer, assembly assembly technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inconsistent pressing depth, large pressing force, pressure difference, etc., to ensure stability and performance , the effect of reducing the pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

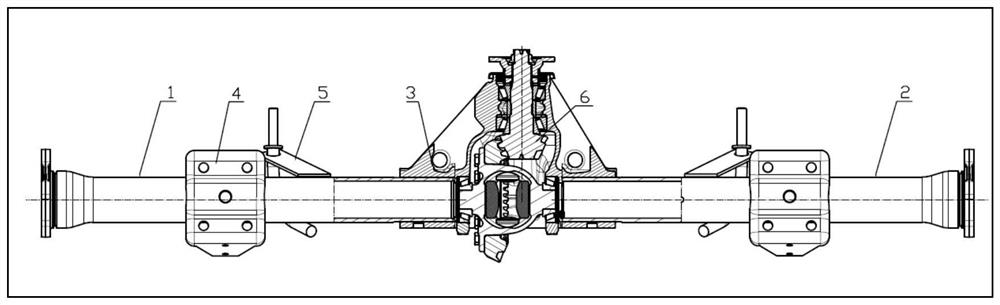

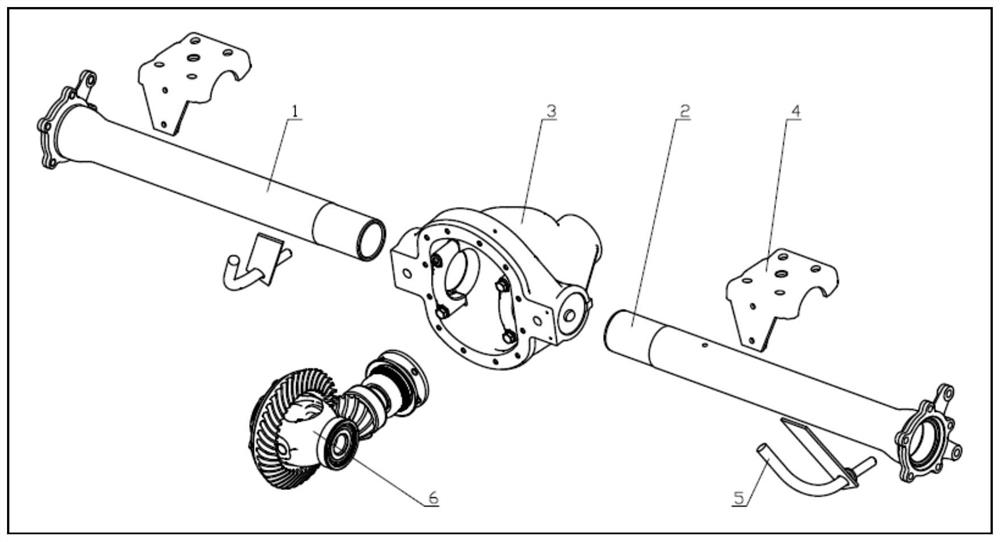

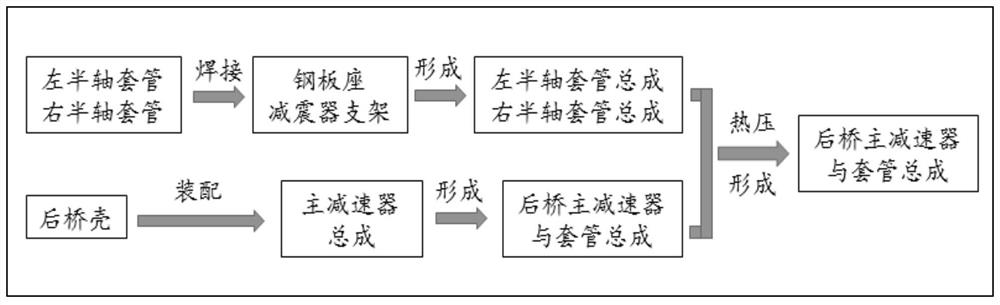

[0033] like image 3 As shown, a rear axle final drive and bushing assembly assembly process of the present invention includes the following steps:

[0034] Step 1. Weld the steel plate seat 4 and the shock absorber bracket 5 on the left half-shaft casing 1 and the right half-shaft casing 2 respectively to form the left half-shaft casing assembly and the right half-shaft casing assembly;

[0035] Step 2. Synchronously, the components of the final drive assembly 6 are sequentially assembled into the rear axle housing 3 on the assembly line to form the final drive drive assembly;

[0036] Step 3. Press the left half-shaft bushing assembly and the right half-shaft bushing assembly formed in step 1 into the rear axle main reducer assembly formed in step 2 at the same time by hot pressing process, and finally form the rear axle main reducer with bushing assembly.

[0037] The rear axle main reducer and sleeve assembly assembly equipment and process provided by the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com