Sealing device

A sealing device and external sealing technology, applied in the directions of engine sealing, transportation and packaging, shafts, etc., can solve the problems of decreased fuel consumption, difficulty in preventing the intrusion of mud and water, and inability to obtain the interference of casing 2, and achieve sliding rotation. The effect of small moment and excellent sealing performance against mud and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

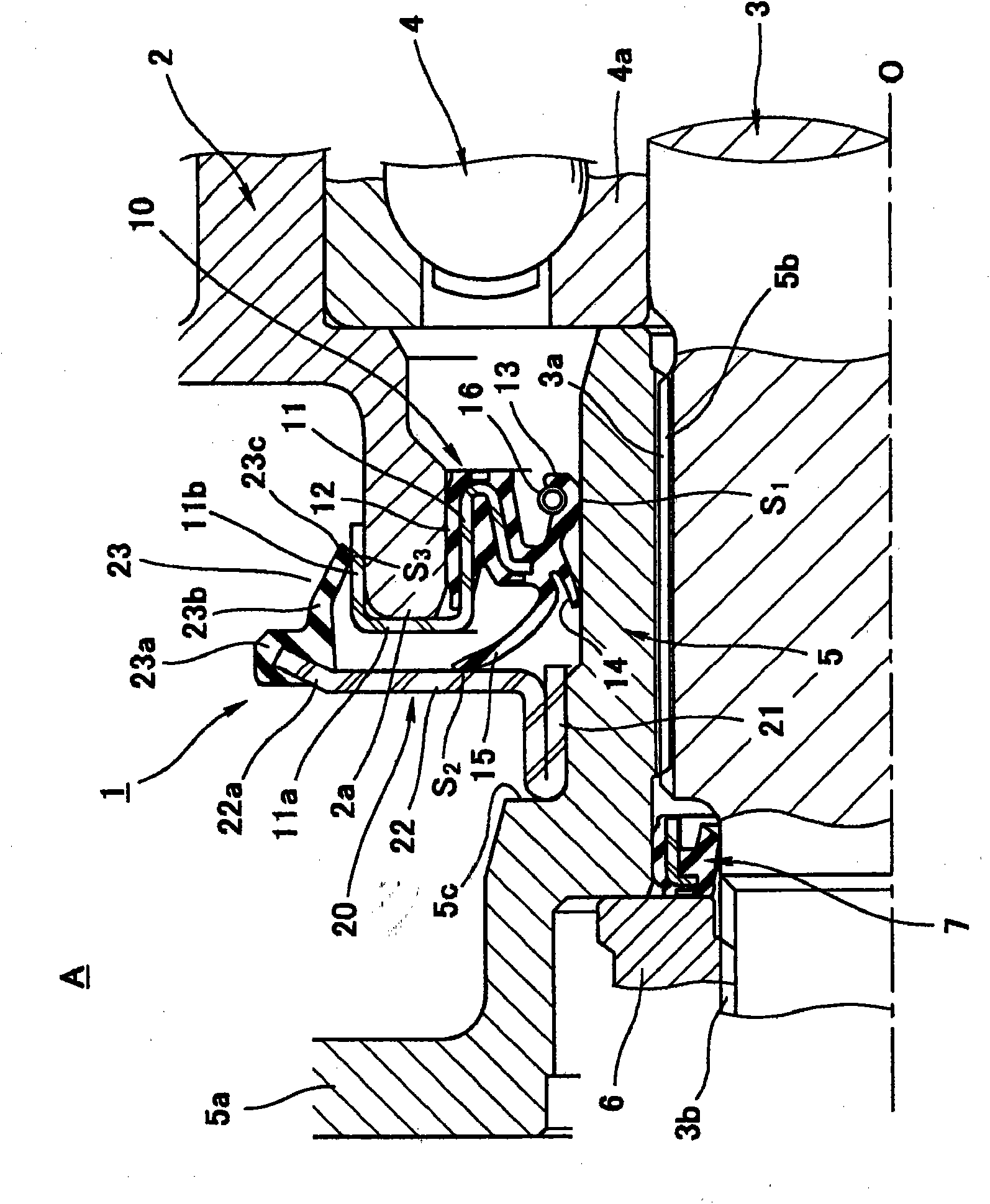

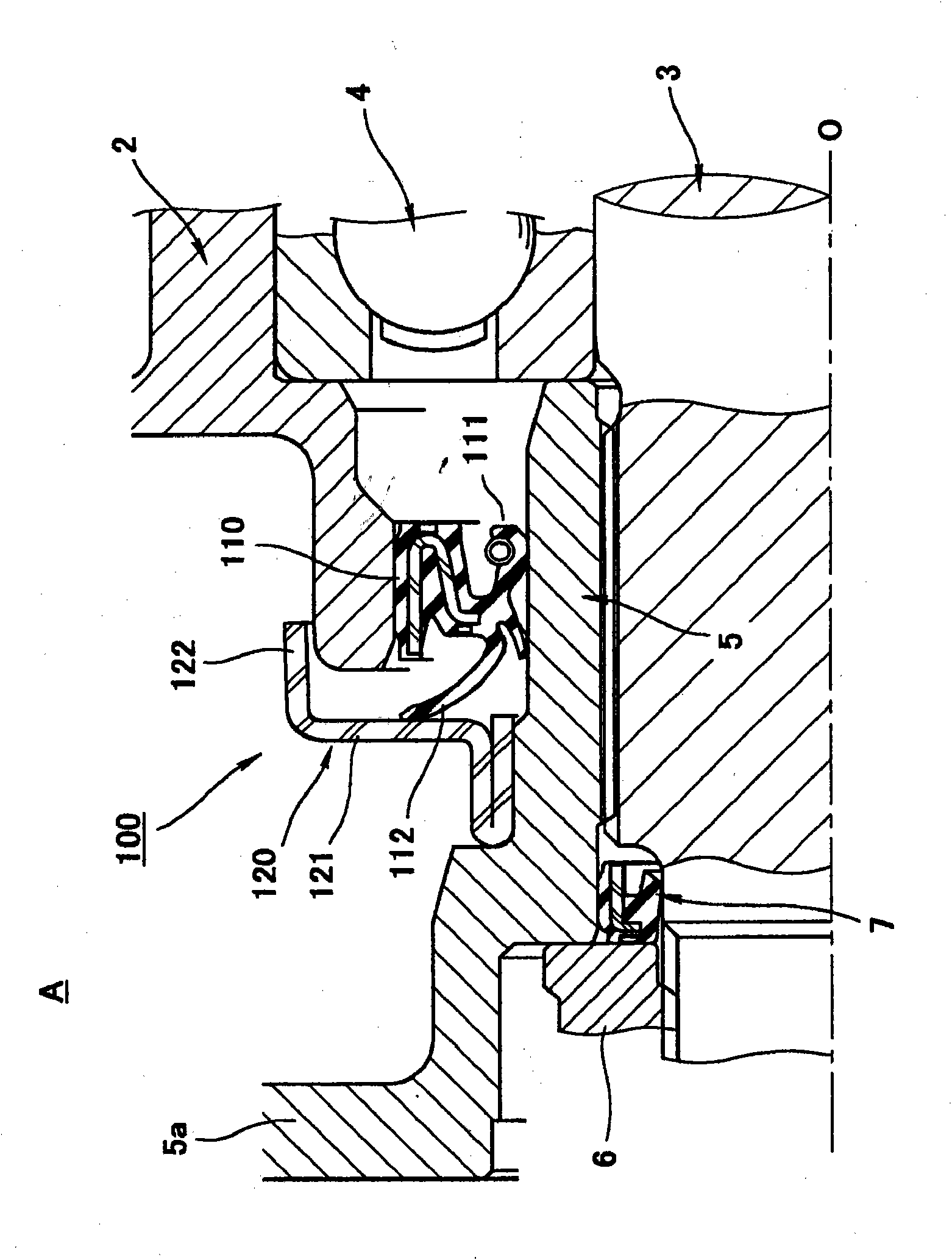

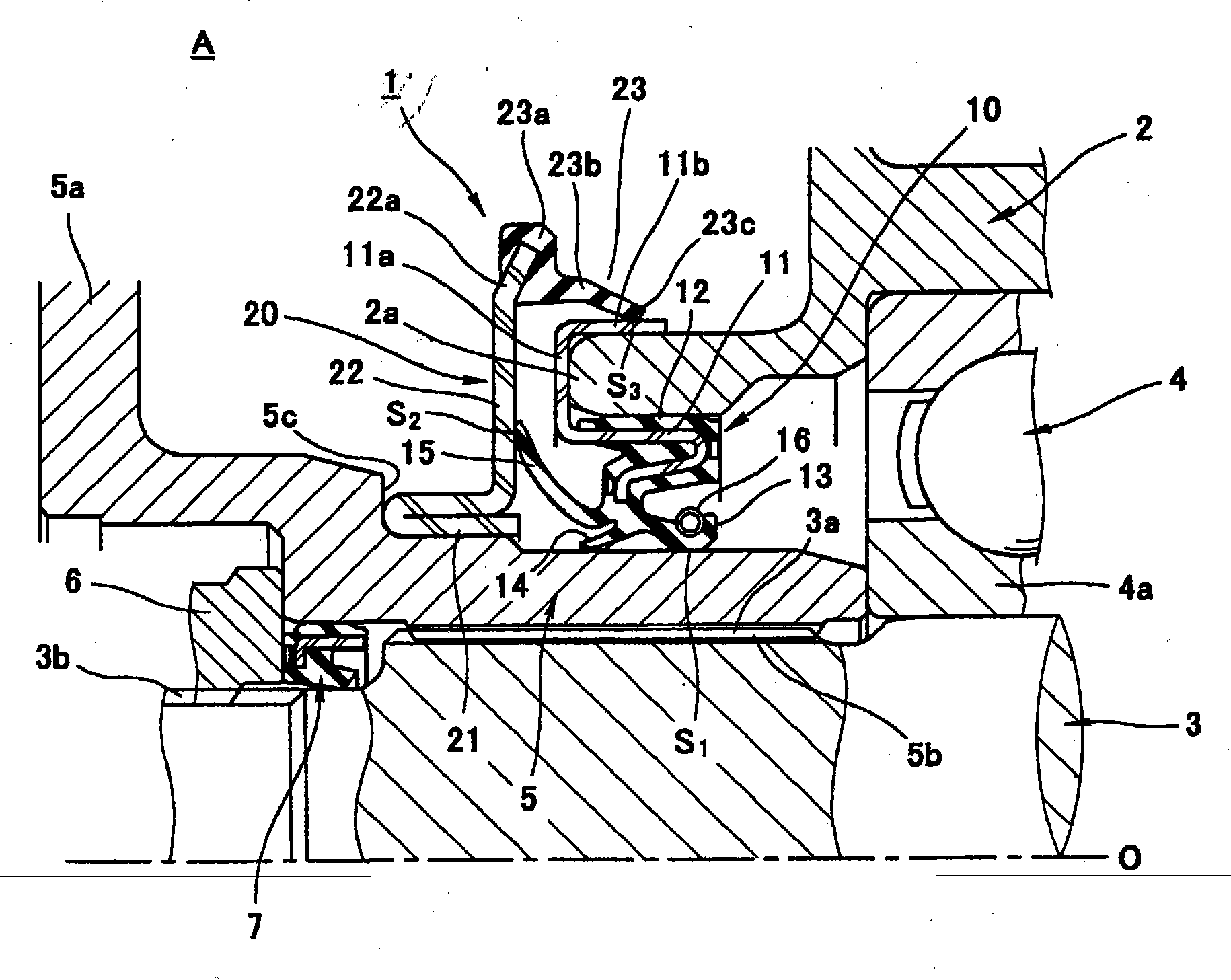

[0040] Hereinafter, embodiments of the sealing device according to the present invention will be described with reference to the drawings. figure 1 It is a half sectional view of the mounted state of the preferred embodiment of the sealing device according to the present invention cut along the plane passing through the axis O. FIG.

[0041] exist figure 1 Among them, the reference numeral 2 is a non-rotating casing on the transmission of the vehicle, the reference numeral 3 is a rotating shaft which is inserted through the above-mentioned casing 2 and is rotatably supported around the axis O through the bearing 4, and the reference numeral 5 It is a sleeve which is located on the inner peripheral side of the opening end portion 2 a of the housing 2 and is externally inserted into the rotating shaft 3 . In addition, the rotating shaft 3 and the sleeve 5 correspond to the rotating body of Claim 1.

[0042] The sleeve 5 is positioned on the outer side in the axial direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com