Adaptive guide wheel device and design method for rail vehicles

A rail vehicle and rail guiding technology, which is applied in the field of guiding wheel devices for rail vehicles and the position adjustment of guiding wheels, can solve the problems of abnormal friction of guiding wheels, uneven gaps, and jamming of guiding wheels by force, so as to improve the reliability of guiding The effect of improving the effectiveness of guidance and the high reliability of guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

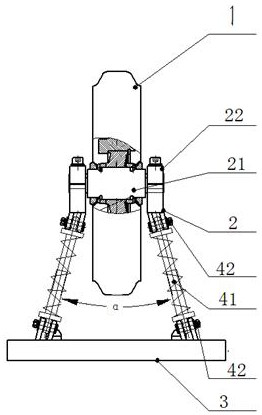

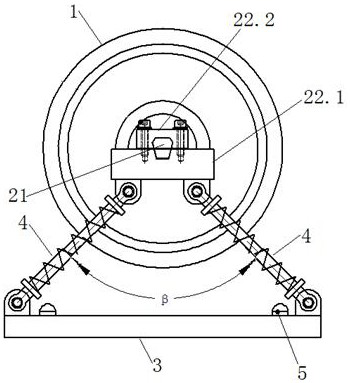

[0027] Attached below Figure 1~4 Embodiments of the present invention are described in detail.

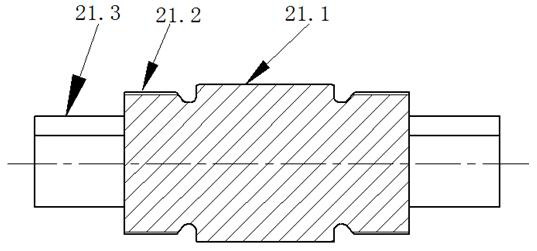

[0028] The self-adaptive guide wheel device for rail vehicles includes a guide wheel 1 that cooperates with the track guide, a wheel shaft 2 installed on the guide wheel 1, a base 3 connected to the car body, and a vibration damper connected between the wheel shaft 2 and the base 3 The shock absorber assembly 4 is characterized in that the number of the shock absorber assemblies 4 is multiple and symmetrically arranged at both ends of the wheel shaft 2. 2 and the base 3 are telescopic and / or swingable to adapt to the operating conditions, so that the guide wheel 1 and the track are kept in a guiding fit and the support wheel shaft 2 is kept vertically arranged to prevent the guide wheel 1 from tilting.

[0029] In the above-mentioned self-adaptive guide wheel device for rail vehicles, the number of shock absorber assemblies 4 is multiple and inclined. When the vehicle is turning,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com