Zirconia insulation structure applied in sapphire single crystal furnace

A sapphire single crystal furnace and zirconia technology, which is applied in the direction of single crystal growth, single crystal growth, and seed crystal remaining in the molten liquid during growth, can solve the problems of difficult temperature field control and easy deformation of molybdenum barrels, and achieve continuous Sensitivity to temperature adjustment, maintaining the temperature in the furnace, and the effect of small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

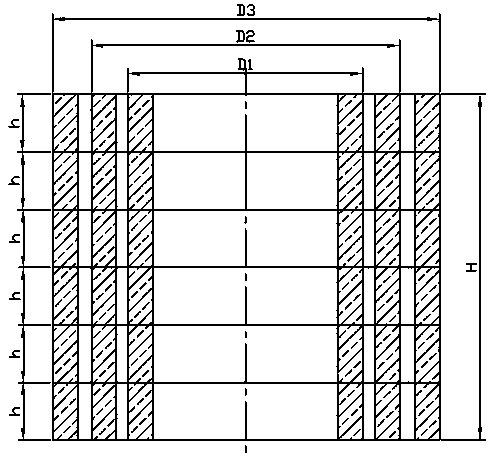

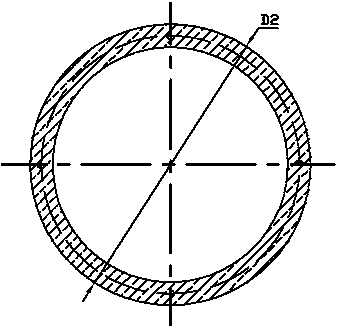

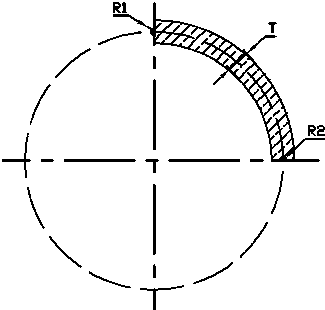

[0026] combine Figure 1-4 , the present embodiment is a 3-layer zirconia heat preservation barrel structure, the outer diameter of the heat preservation barrel from inside to outside is D1, D2 and D3 successively, and D1, D2 and D3 are 500mm, 550mm, 600mm respectively. this invention figure 1 It shows that the height of the zirconia insulation barrel is H, and it is composed of four rings of zirconia fiber brick rings with a height of h, and h is 100mm. Figure 2-4 It is the structural diagram of splicing rings of zirconia insulation barrels. The thickness T of the zirconia fiber brick rings is 20mm. It can be seen from the figure that the two adjacent zirconia fiber brick rings in the ring are connected up and down between each zirconia brick. There are matching positioning protrusions and positioning grooves with radii R1 and R2 at each location, R2 is slightly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com