Saddle structure of large-volume low-temperature vacuum storage and transportation container

A low-temperature vacuum and large-volume technology, which is applied to container discharge methods, pressure vessels, container filling methods, etc., can solve problems that cannot meet the requirements of low-temperature medium loading and transportation, improve safety and reliability, improve stress conditions, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

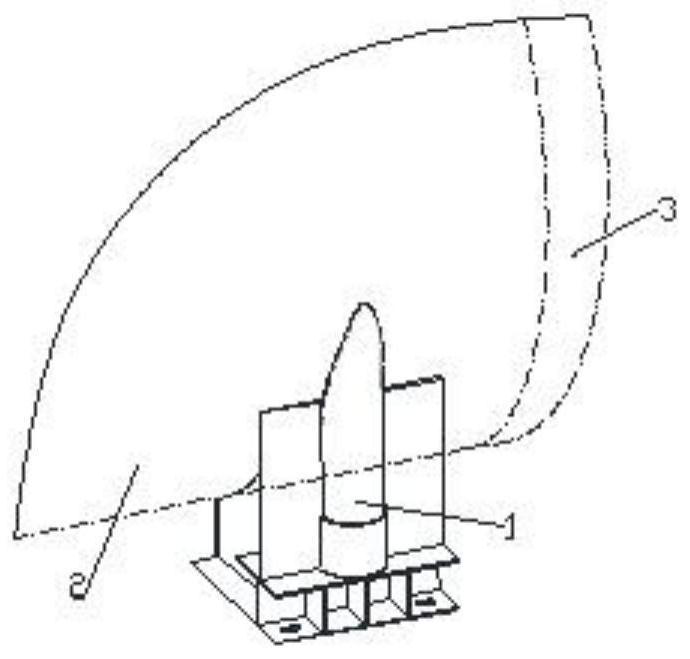

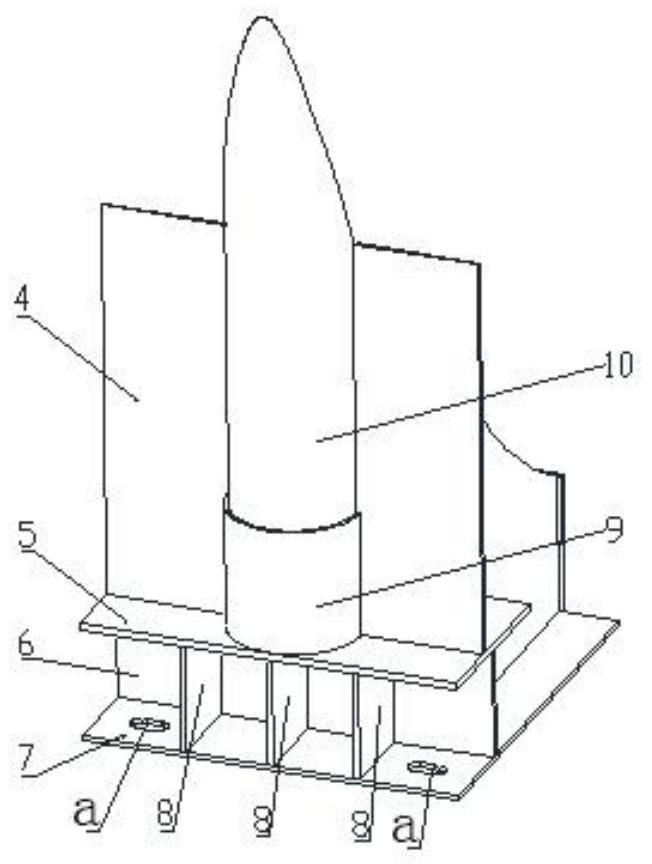

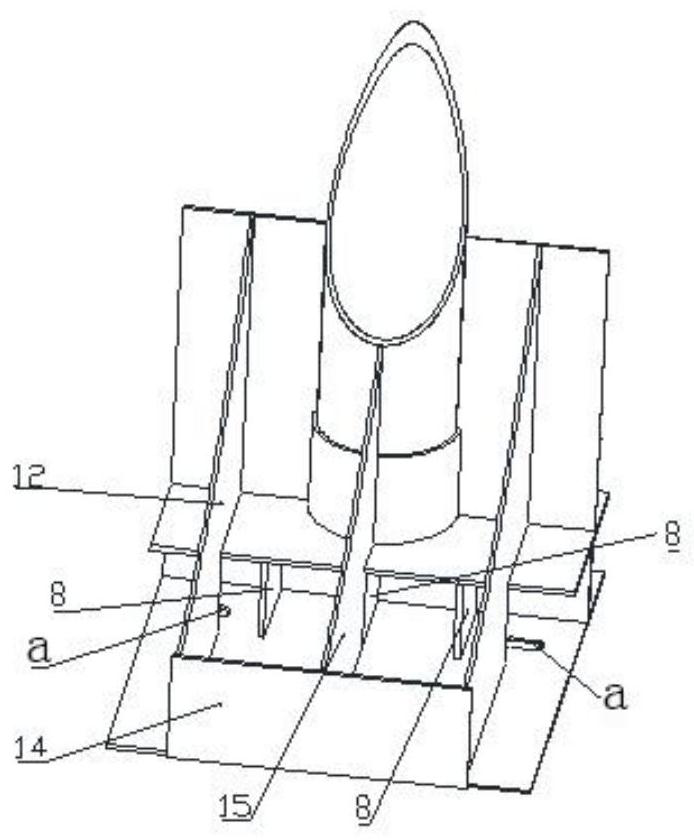

[0035] The tank body of a large-volume low-temperature vacuum storage and transportation container usually includes an inner tank body and an outer tank body, both of which include a cylinder body and caps 3 arranged at both ends of the cylinder body. The present invention provides a saddle structure 1 of a large-volume cryogenic vacuum storage and transportation container, such as Figure 1 to Figure 3 As shown, it includes a first protective tube 10, a second protective tube 9, a bottom sealing plate 5, a height adjustment unit and a reinforcing unit; The through hole provided on the wall 2 is assembled and welded, the lower end of the first protective tube 10 is sleeved on the upper end of the second protective tube 9, the outer wall of the lower end of the first protective tube 10 is fitted with the inner wall of the upper end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com