Pipe fitting internal thread incremental rolling-extruding forming device

A technology of internal thread and rolling extrusion, applied in the field of pipe fittings forming equipment, can solve the problem of low quality of internal thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

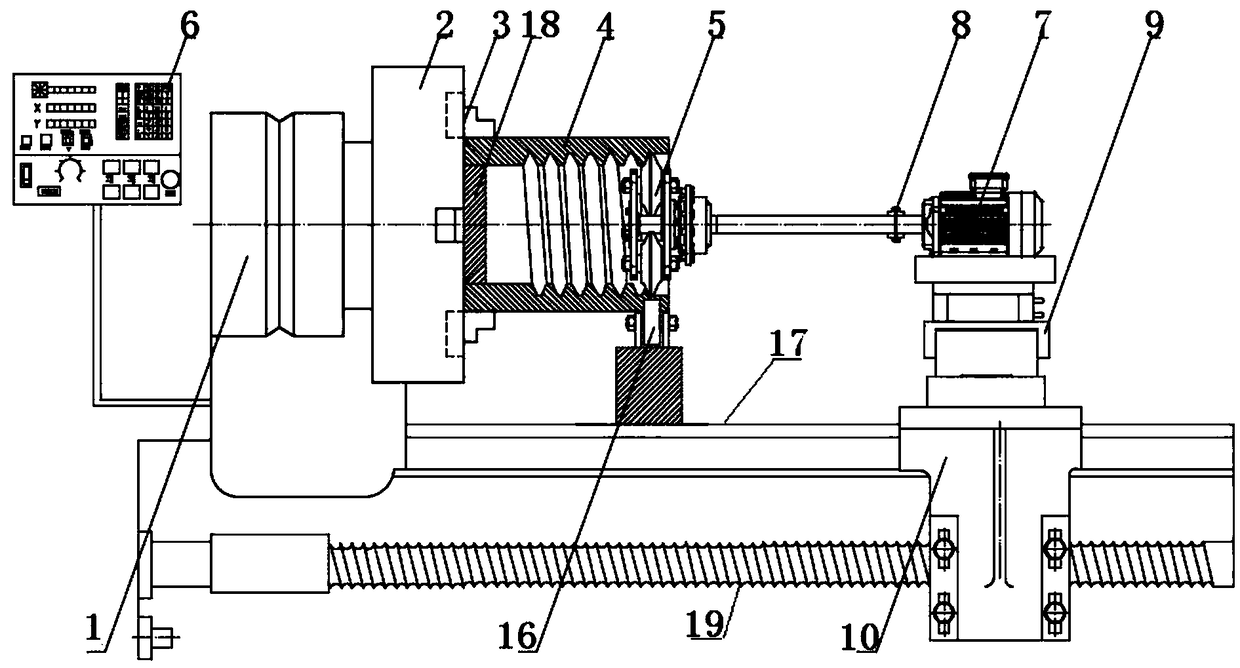

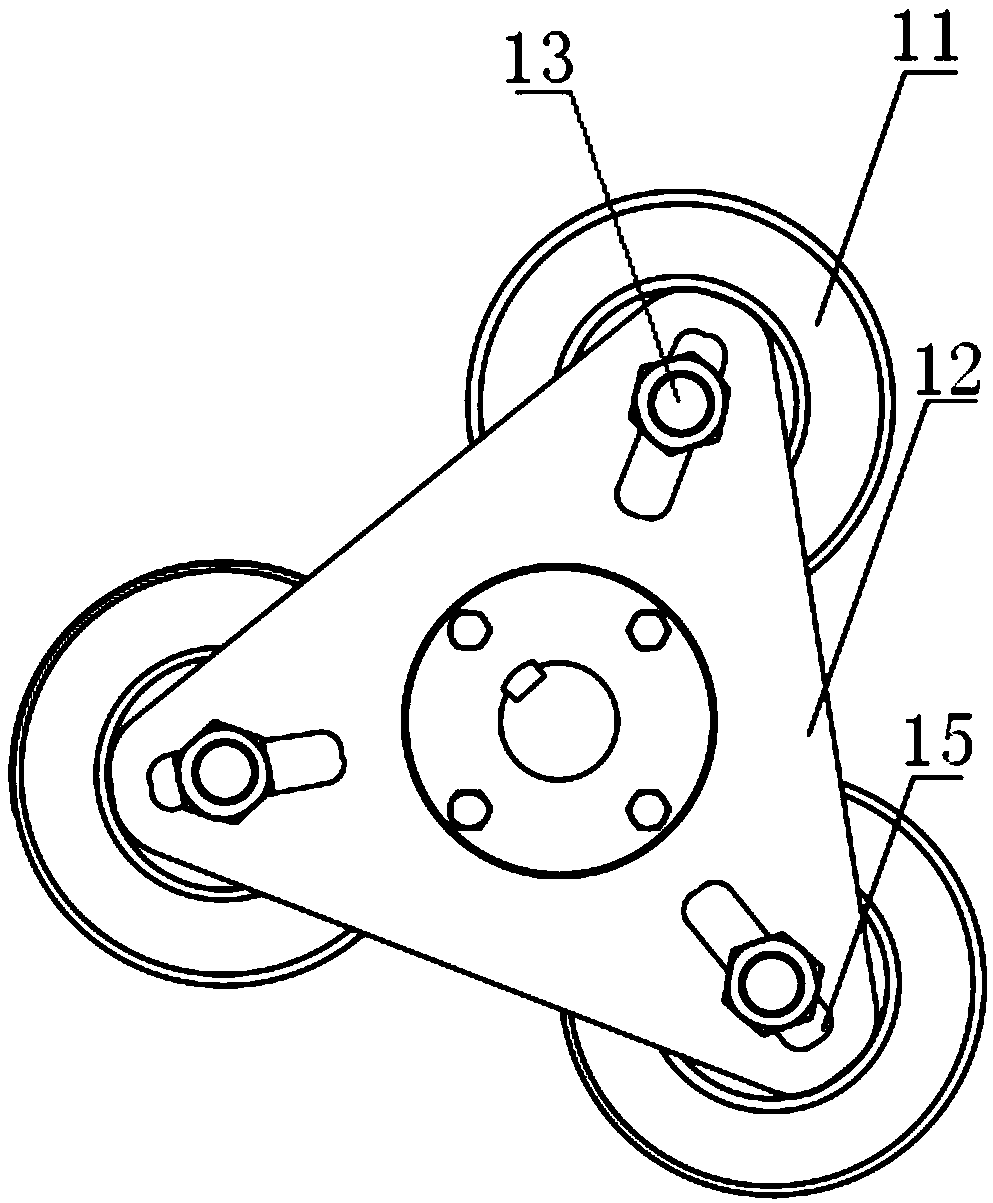

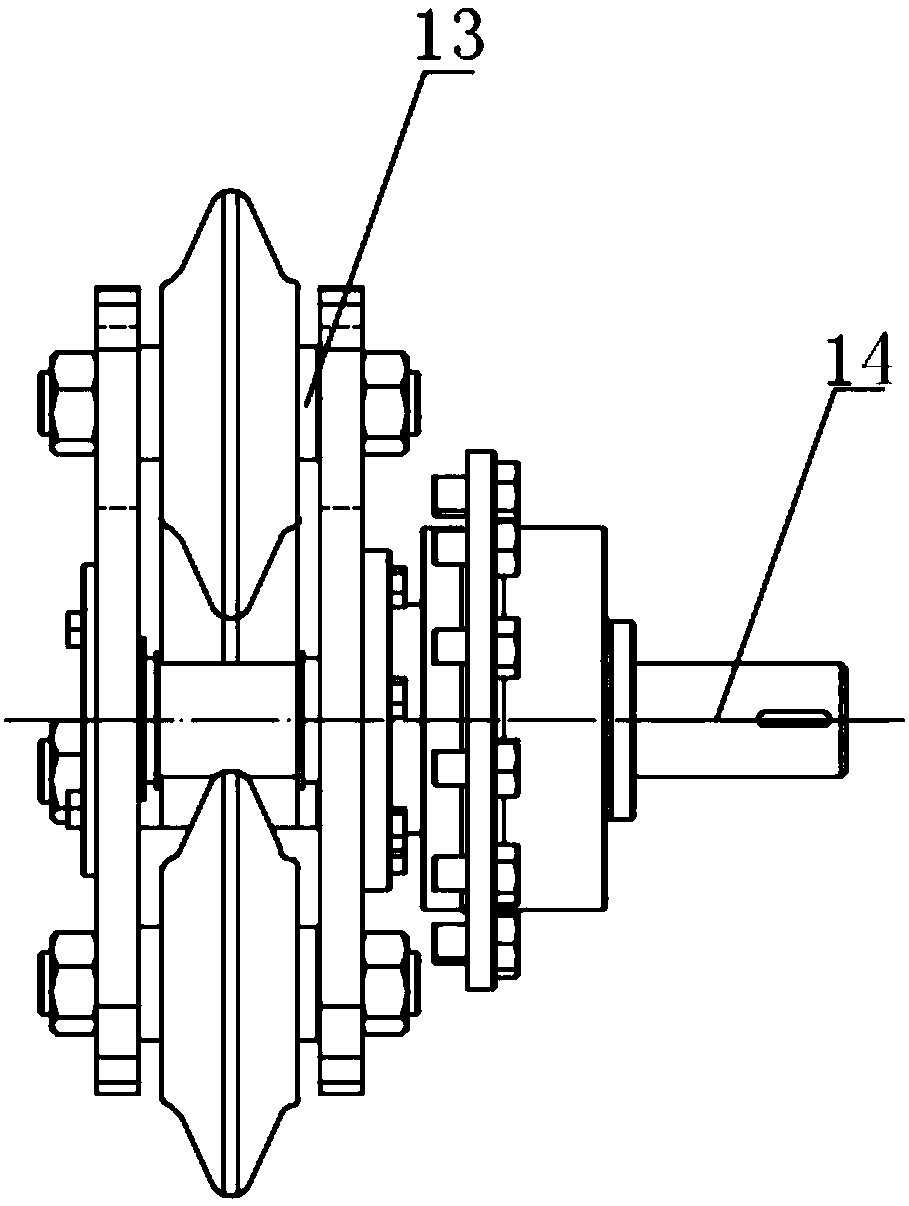

[0021] The present invention is an incremental rolling extrusion forming device for internal threads of pipe fittings, such as figure 1 As shown, it includes the motorized spindle housing 1 of the CNC machine tool. One side of the motorized spindle cabinet 1 is connected with a centering chuck 2. One side of the centering chuck 2 is fixed with a claw 3, and a pipe sample is fixed inside the claw 3. 4. The pipe fitting sample 4 is a thick-walled cylindrical metal blank, and the thick-walled cylindrical metal blank is fixed by the radial clamping force of the centering chuck 2 and the jaws 3, so as to ensure that the thick-walled cylindrical metal blank does not produce axial damage. Moving, the pipe fitting sample 4 is provided with a rolling forming tool wheel 5, one end of the rolling forming tool wheel 5 is connected with a driving device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com