A solid oxide fuel cell cathode gas flow field plate and its preparation method

A fuel cell cathode and solid oxide technology, which is applied in the direction of fuel cells, fuel cell parts, electrical components, etc., can solve the problems of large gas pressure drop and low fuel utilization rate, and overcome the large gas pressure drop and reduce the The effect of high contact resistance and product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

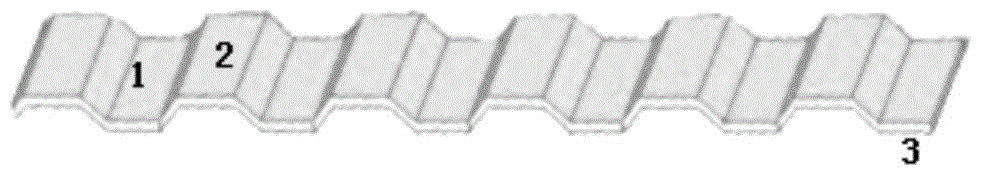

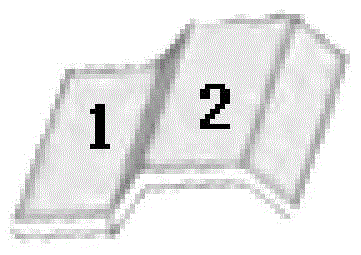

[0043] S1: Design and process the rolling wheel, wherein, according to the point-to-point mapping from the flat plate to the rolling wheel circumference, design a pair of active rolling wheels and driven rolling wheels that can engage with each other, and assemble them in a fixed place after processing On the rolling mill of the above-mentioned pair of rolling wheels, the surface of the pair of rolling wheels has a punch and a die that are precisely matched when they are engaged with each other, and the punch of the driving rolling wheel matches the die of the driven rolling wheel. When the two are engaged, the metal sheet to be processed is plastically deformed to obtain a flat-topped boss with a corrugated tooth shape;

[0044] S2: Adjust the gap between the active rolling wheel and the driven rolling wheel according to the thickness of the metal sheet to be processed. The gap is the top surface 5 of the punch and the bottom surface 6 of the die when the pair of rolling wheel...

Embodiment 2

[0049] This embodiment is the same as Embodiment 1, the difference is:

[0050] In step S2, a metal copper plate with a thickness of 0.5 mm is used as a thin metal plate to be processed to prepare a fuel cell cathode gas flow field plate, and the gap is adjusted to 0.5 mm to obtain a copper fuel cell cathode gas flow field plate.

Embodiment 3

[0052] This embodiment is the same as Embodiment 1, the difference is:

[0053] In step S2, a metal aluminum plate with a thickness of 0.6 mm is used as a thin metal plate to be processed to prepare a solid oxide fuel cell cathode gas flow field plate, and the gap is adjusted to 0.6 mm to obtain an aluminum fuel cell cathode gas flow field plate.

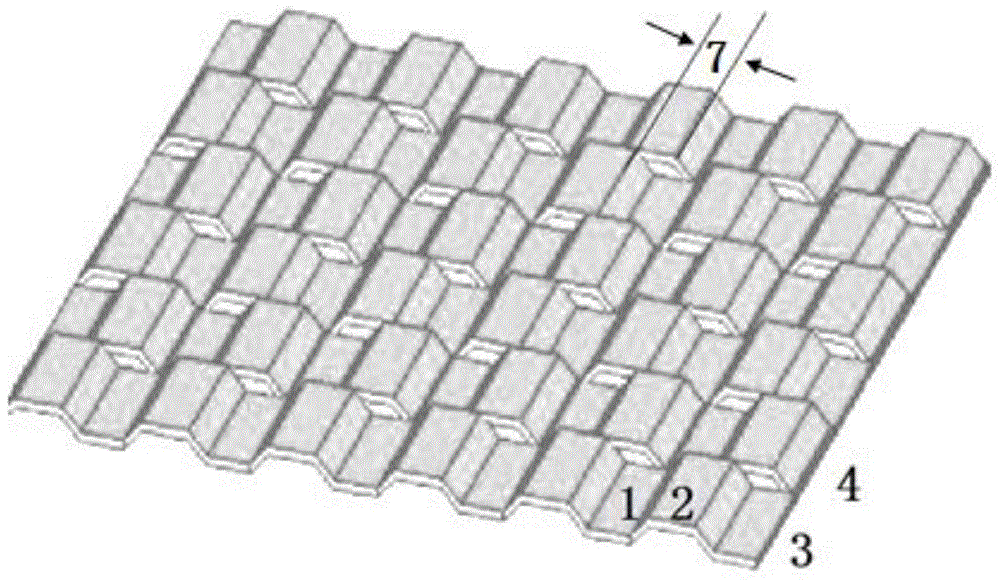

[0054] Figure 4 It is a schematic diagram of the processing state of a pair of rolling wheels in the embodiment of the present invention, specifically the schematic diagram of the processing state of embodiment 1. Feed the metal sheet to be processed to a pair of rolling wheels along the fixed track (not shown in the figure), and the metal sheet is deformed and then sent out from the other side of the pair of rolling wheels to obtain the cathode gas of the fuel cell in the present invention. Flow field plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com