A kind of pvc co-extrusion foam floor and preparation method thereof

A floor and foam layer technology, applied in the direction of elastic floor, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems that it is difficult to meet the appearance requirements, the wood grain becomes shallow, and the wood grain is not obvious, etc., to achieve The effect of clear structure, improved combination, and more structured structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

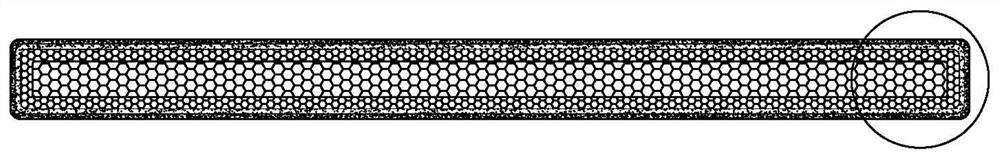

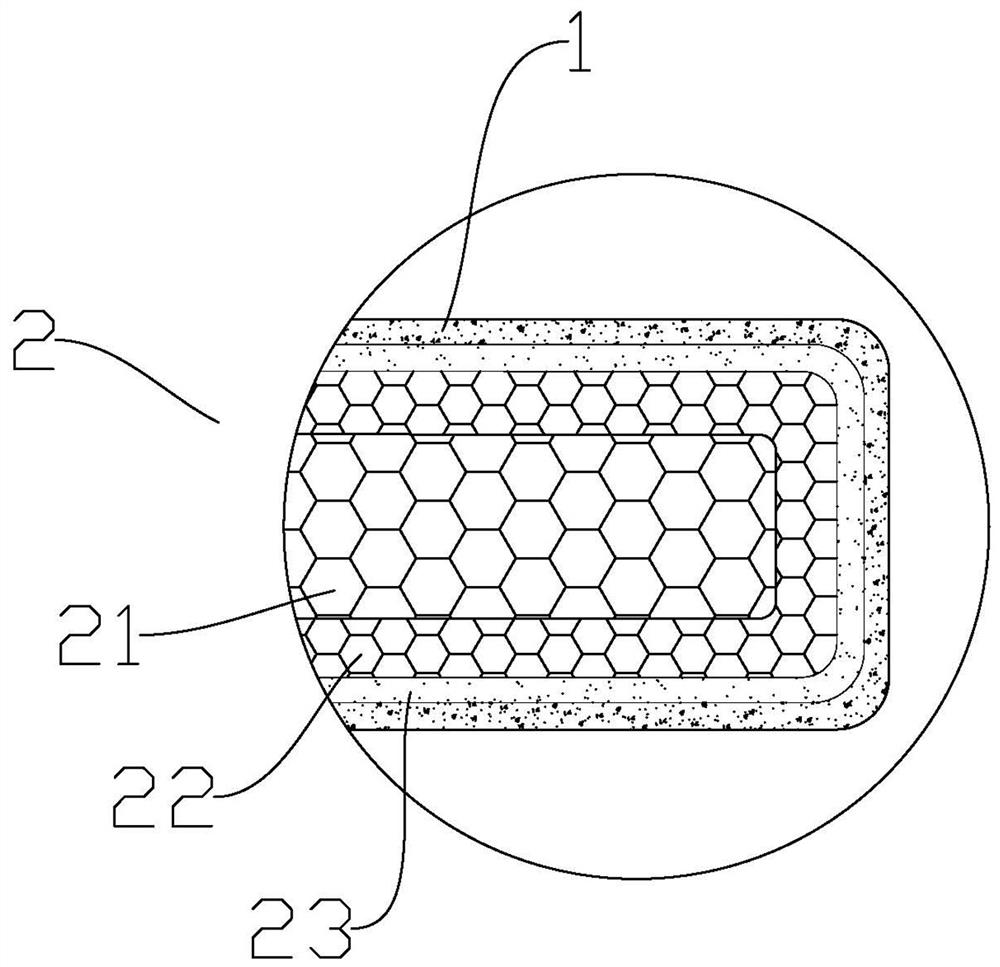

[0078] like Figure 1-2 As shown, a PVC co-extrusion foaming floor includes a PVC foam 2 and a plastic surface layer 1. The PVC foam core 2 includes a first foam layer 21, a second foam layer 22, and a binder layer 23, and the second foam layer 22 is covered with the first foam layer 21, which is coated The second foam layer 22, and each layer of the PVC foam core 2 is integrated.

[0079] In the present embodiment, the material of the plastic surface is ASA. The ASA plastic surface layer 1 is covered with the surrounding layer 23. The first foam layer 21 is a low density foam layer, according to the size of the cell, the density estimate is 0.5 g / cm. 3 Left and right; the second foam layer 22 is a high-density foam layer, according to the size of the cell, the density estimate is 0.7 g / cm 3 about. The plastic surface layer 1 has a wood texture; the thickness of the collision layer 23 is 0.6 cm.

[0080] like Figure 3 ~ 4 As shown, the preparation method of the above PVC co-ext...

Embodiment 2

[0089] The PVC co-extrusion floor of the present embodiment differs from the examples only between the PVC foam 2 and the plastic surface layer 1. like Figure 5 As shown, the connection structure includes a multi-row bonding groove 23-1 disposed on the upper surface of the lithopsellation layer 23 and a multi-row connection protrusion 1-1 disposed on the lower surface of the plastic surface layer 1, the binding groove 23 The setting direction of the -1 is parallel to the length direction of the floor, and the connecting projections 1-1 form a corresponding mating structure and inlaid in the binding groove 23-1.

[0090] like Figure 5 As shown, the binding groove 23-1 includes a groove portion portion that is connected to the upper surface of the degenerate layer 23 and a groove body portion that is connected to the slot portion and disposed below it, the slot body The portion has a larger width than the slot port. The groove portion is transitioned between the portion of the groov...

Embodiment 3

[0100] The PVC co-extrusion floor of the present embodiment is different from the example in which the plastic surface layer 1 has two surface layers.

[0101] That is, relative to the embodiment one, there is a need to add a co-extruded package plate; the specific method is as follows.

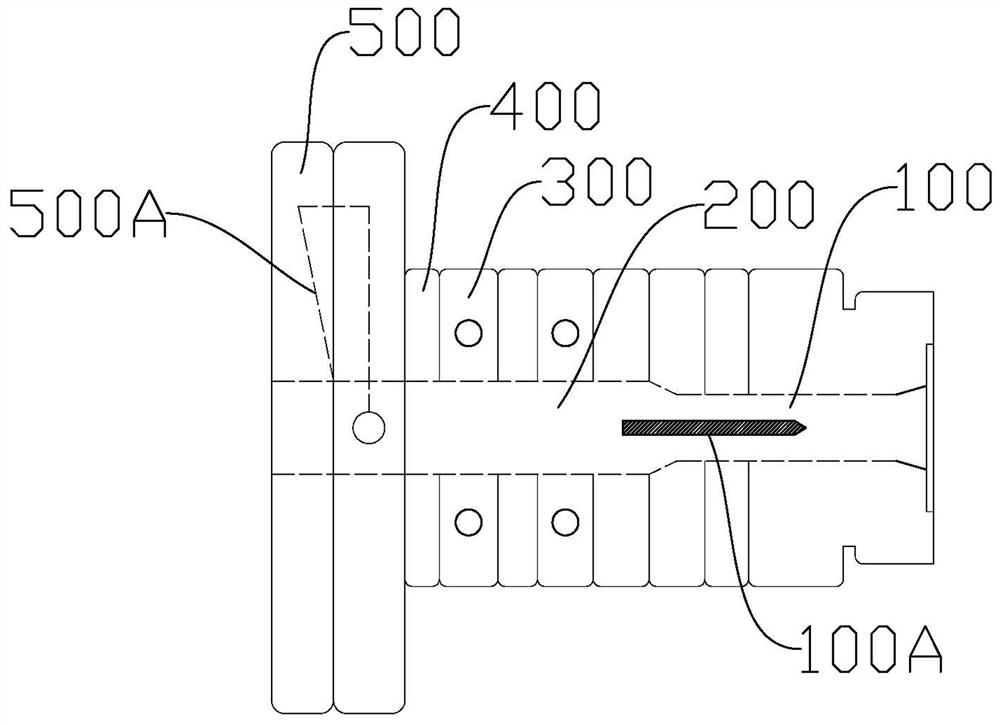

[0102] like Figure 6-8 As shown, a method of preparing a PVC co-extrusion foaming floor includes the following steps:

[0103] A. Add the raw material constituting the bubble core and its additive to the main extruder, the raw material and its additive are molten in the main extruder, into the main runway 100 of the mold, and then enter the foaming cavity of the mold The foam is performed in 200, and then passes through the first cooling plate 300 of the mold extruded from the outlet of the core layer extruder 400 of the mold, the PVC foam core 2 is formed; the mold includes a barrier core 100A, the blocking core 100A is basically in mainstream passage 100, while the tail end of the barrier core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com