A CNC pipe bending machine control system

A technology of control system and pipe bending machine, which is applied in the field of pipe bending processing, can solve the problems of low precision, high replacement labor intensity, low movement and positioning precision, etc., and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

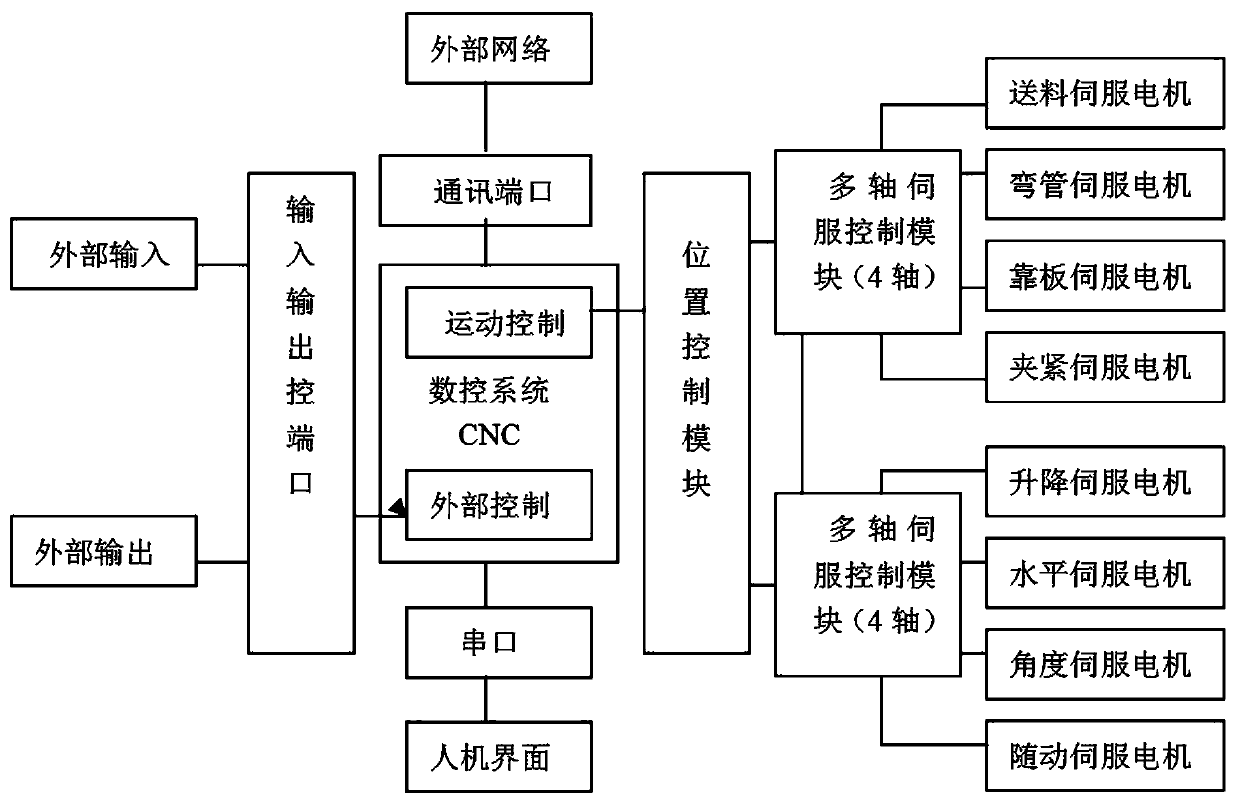

[0036] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0037] A numerically controlled pipe bender control system, comprising a central controller, external input devices, external output devices, and execution components of the pipe bender, the central controller is respectively connected to the external input device and the external output device through input and output ports, and the The central controller establishes a signal connection with the pipe bending machine executive components; the central controller is provided with a motion control module and an external control module, and the external control module is used to receive the data input by the external input device and input the external input device The data is converted into motion control data and transmitted to the motion control module, and the motion control module transmits the motion control data transmitted by the external control m...

Embodiment 2

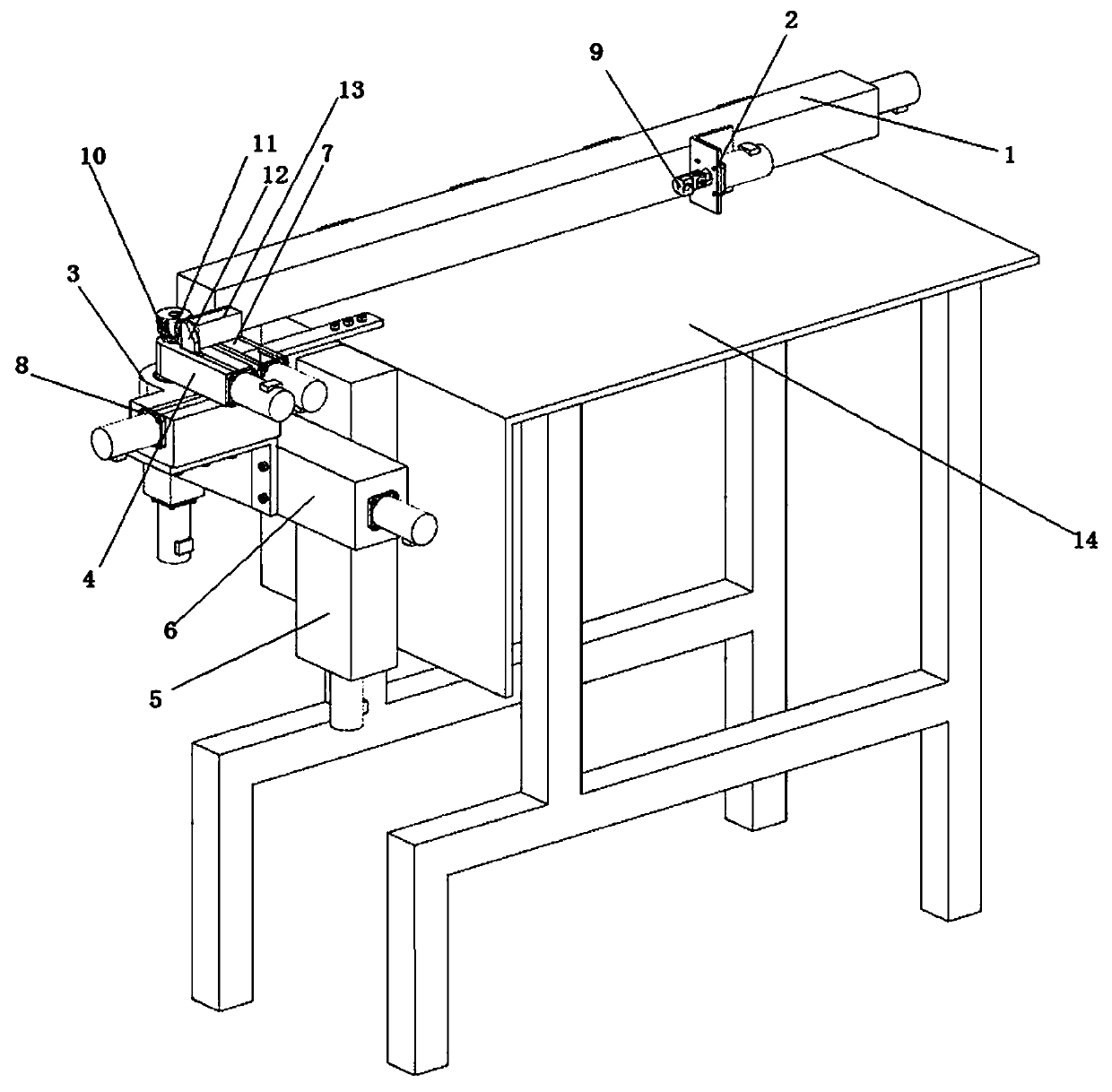

[0040] As another preferred embodiment of the present invention, with reference to the attached Figure 1-5 , this example discloses:

[0041] A numerically controlled pipe bender control system, comprising a central controller, external input devices, external output devices, and execution components of the pipe bender, the central controller is respectively connected to the external input device and the external output device through input and output ports, and the The central controller establishes a signal connection with the pipe bending machine executive components; the central controller is provided with a motion control module and an external control module, and the external control module is used to receive the data input by the external input device and input the external input device The data is converted into motion control data and transmitted to the motion control module, and the motion control module transmits the motion control data transmitted by the external ...

Embodiment 3

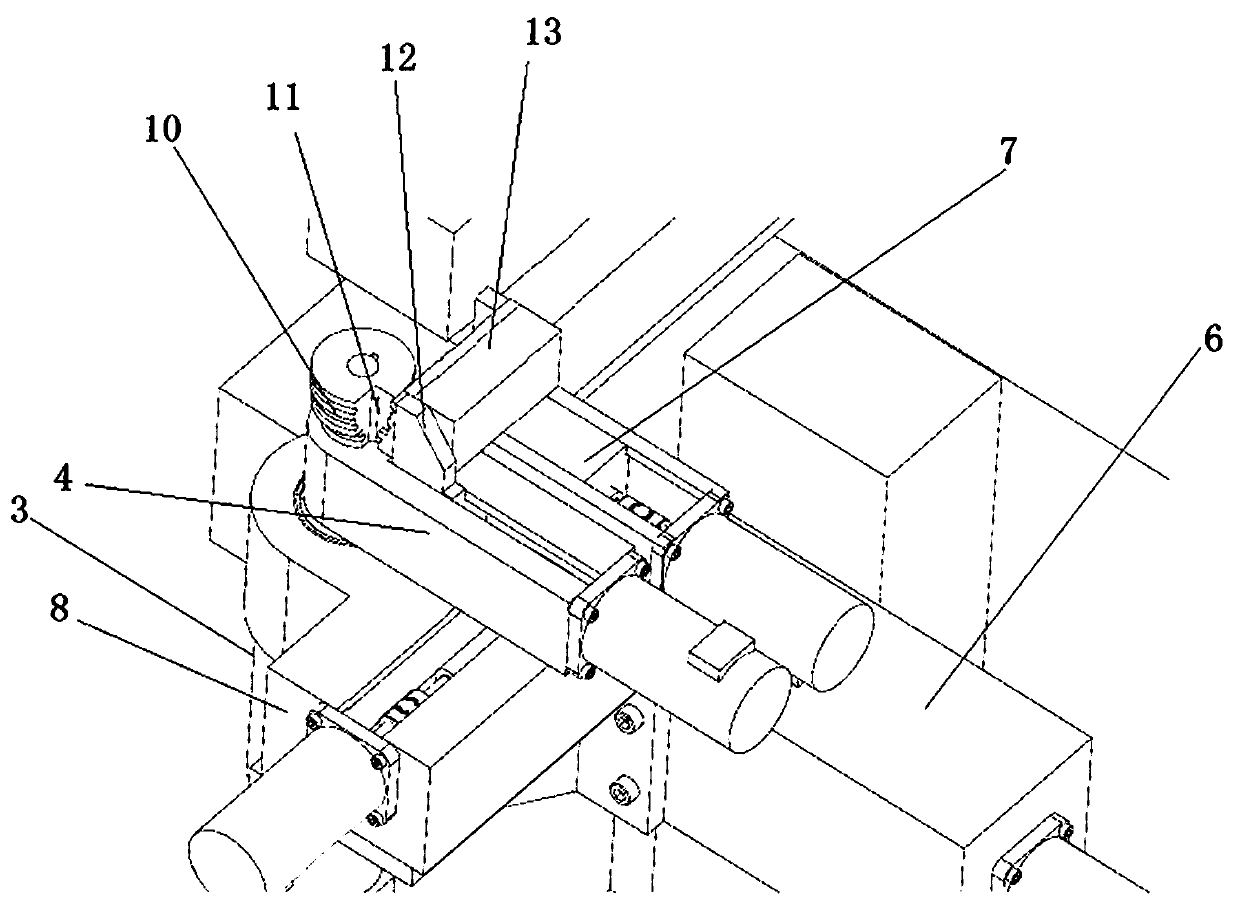

[0046] refer to figure 1 and figure 2 , the control system of the present invention adopts 8 servo motors to respectively control the feeding servo motor, bending pipe servo motor, leaning plate servo motor, clamping servo motor, lifting servo motor, horizontal movement servo motor, angle rotation servo motor, and follow-up servo motor . The feeding servo motor drives the feeding shaft X to do the feeding movement. The pipe bending servo motor drives the pipe bending axis Y to perform the rotating pipe bending action. The backing plate servo motor drives the backing plate to move radially along the pipe material, and fixes the pipe material between the pipe bending mold 10 and the backing plate (the bending of the pipe is equal to the reverse force when the pipe is bent and deformed). The clamping servo motor drives the clamping shaft to clamp the pipe on the pipe bending die 10 . The lifting servo motor drives the lifting shaft B to move up and down to adjust the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com