Patents

Literature

41results about How to "Guaranteed follow-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

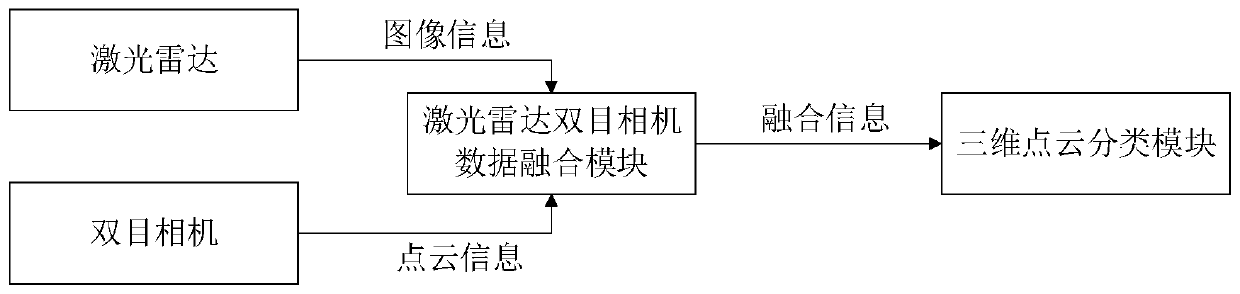

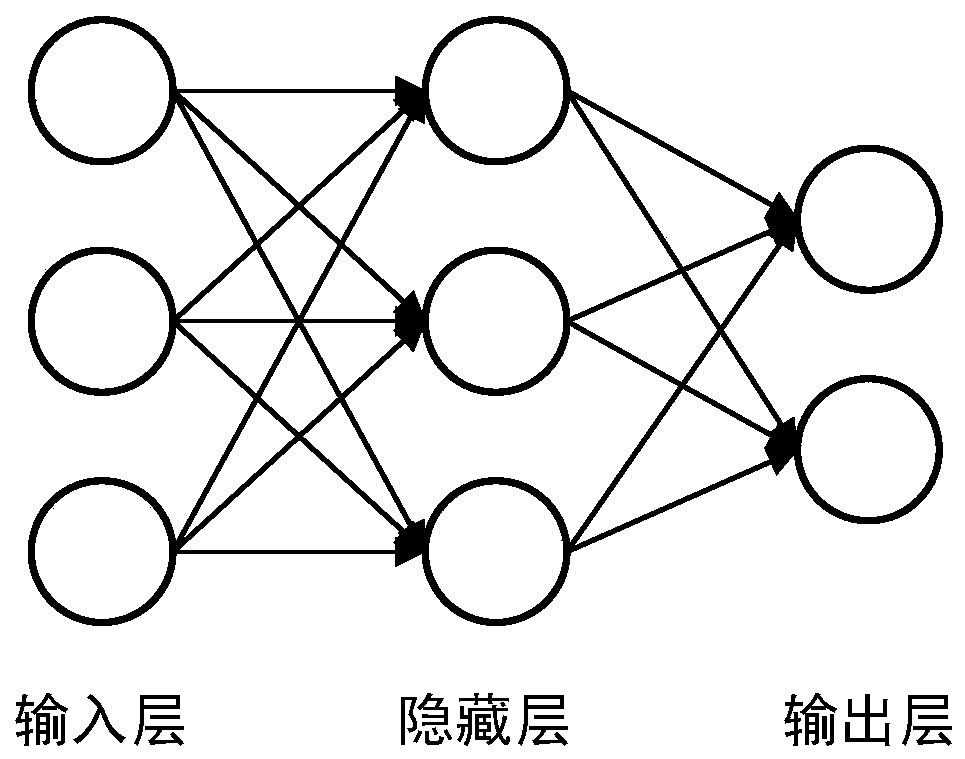

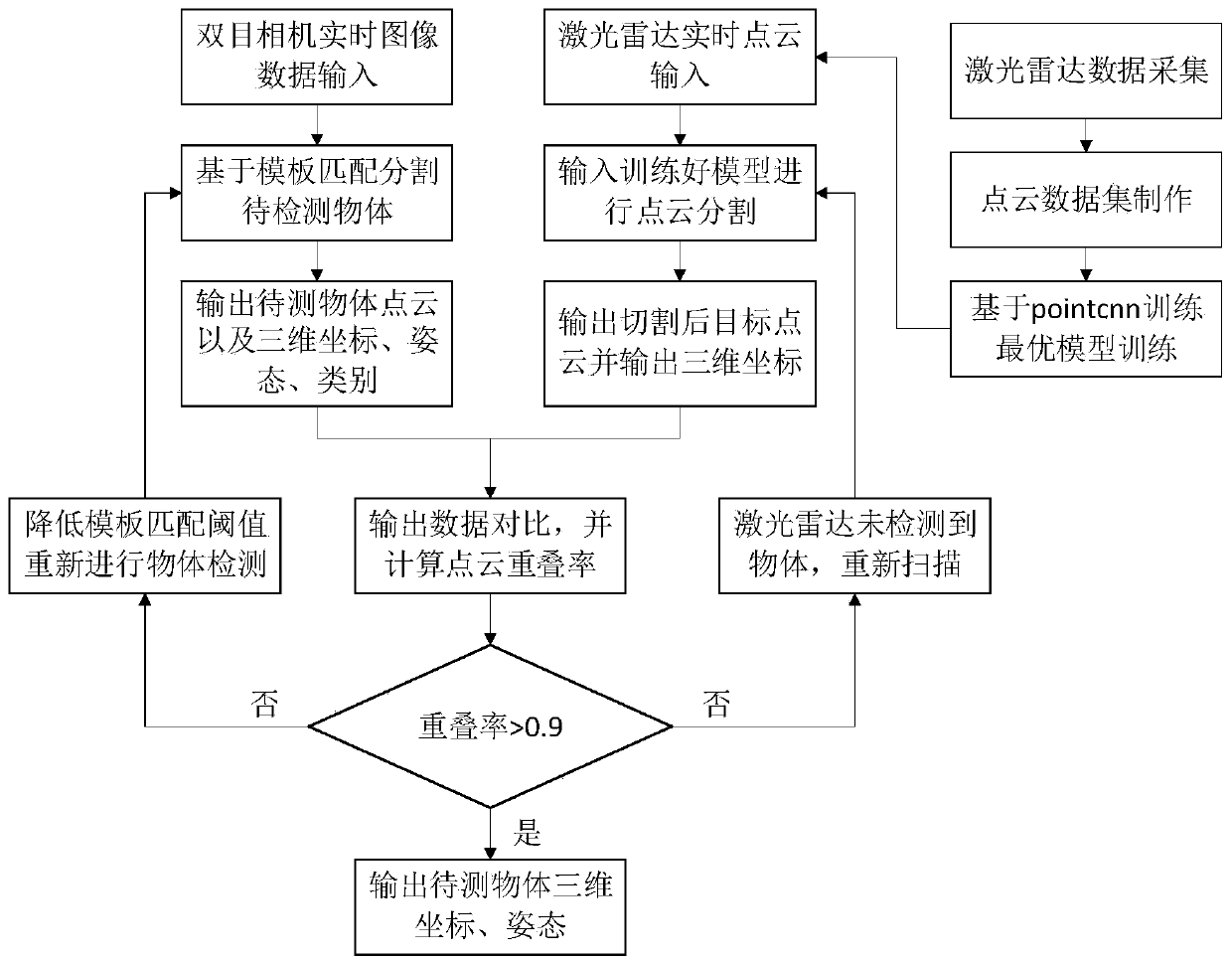

Laser radar and binocular camera data fusion detection method and system

ActiveCN111340797AImprove Bit Measurement AccuracyAccurate detectionImage enhancementImage analysisPoint cloudRadiology

The invention provides a laser radar and binocular camera data fusion detection method and system. The method includes: acquiring point cloud data of a detection area acquired by a laser radar; acquiring image data of a to-be-detected object acquired by the binocular camera; processing the image data, and segmenting the to-be-detected object to obtain point cloud, three-dimensional coordinates, postures and categories of the to-be-detected object; segmenting the directly acquired point cloud data to obtain target point cloud and three-dimensional coordinates thereof; and performing registration and overlapping rate calculation on the two pieces of point cloud data, if the overlapping rate is greater than a set value, outputting a three-dimensional coordinate result of the target point cloud, and otherwise, performing point cloud and image detection of the detection area again. And the target object position measurement precision is effectively improved.

Owner:SHANDONG UNIV

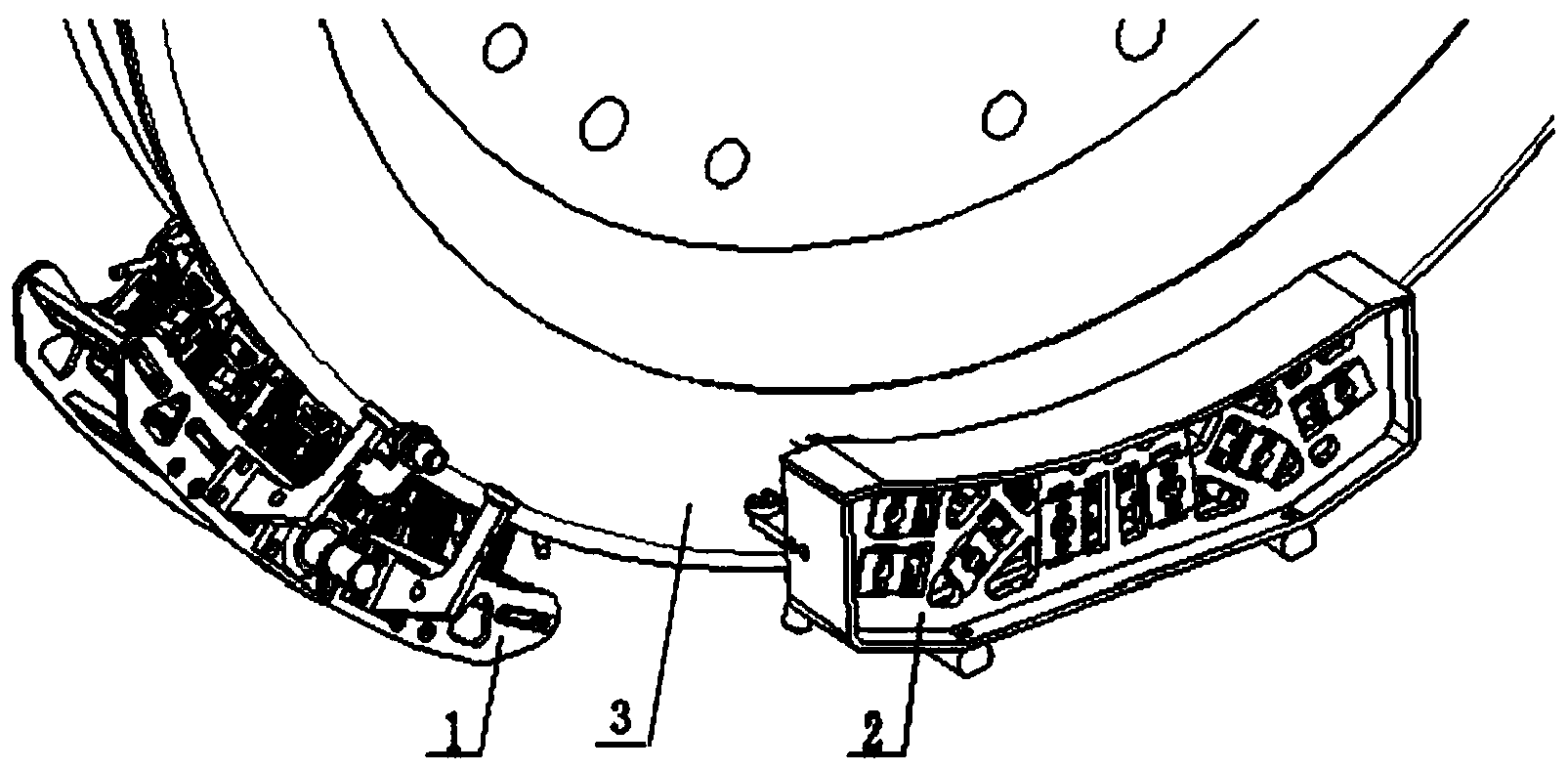

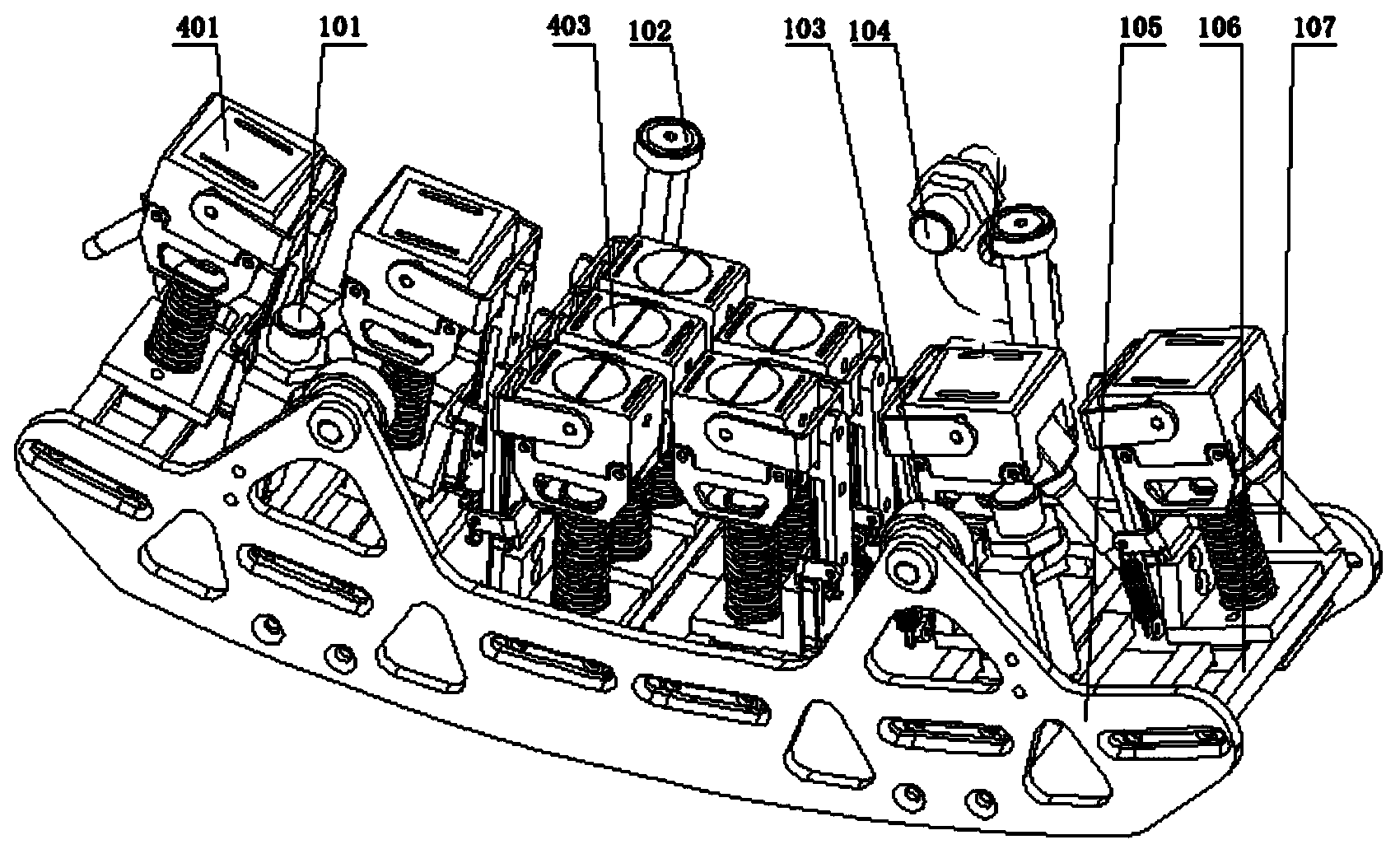

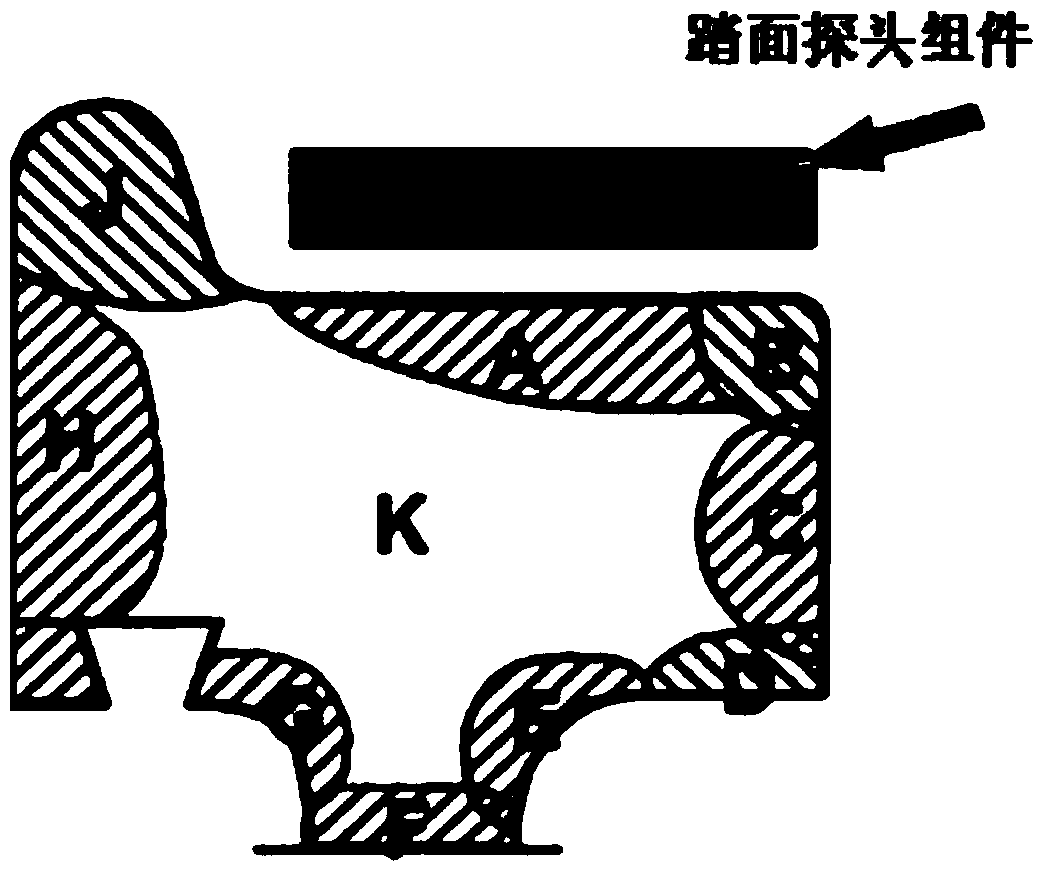

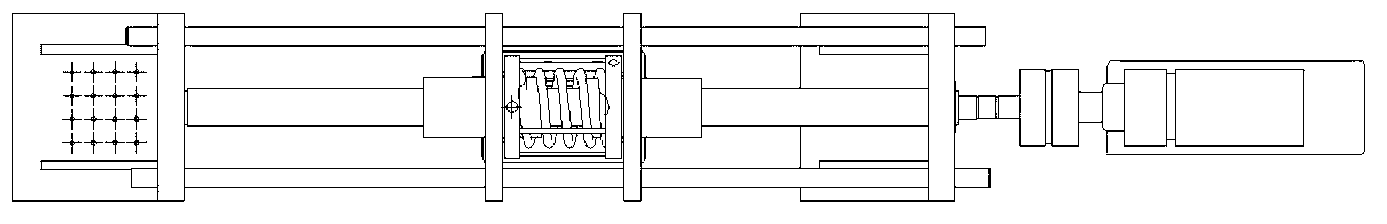

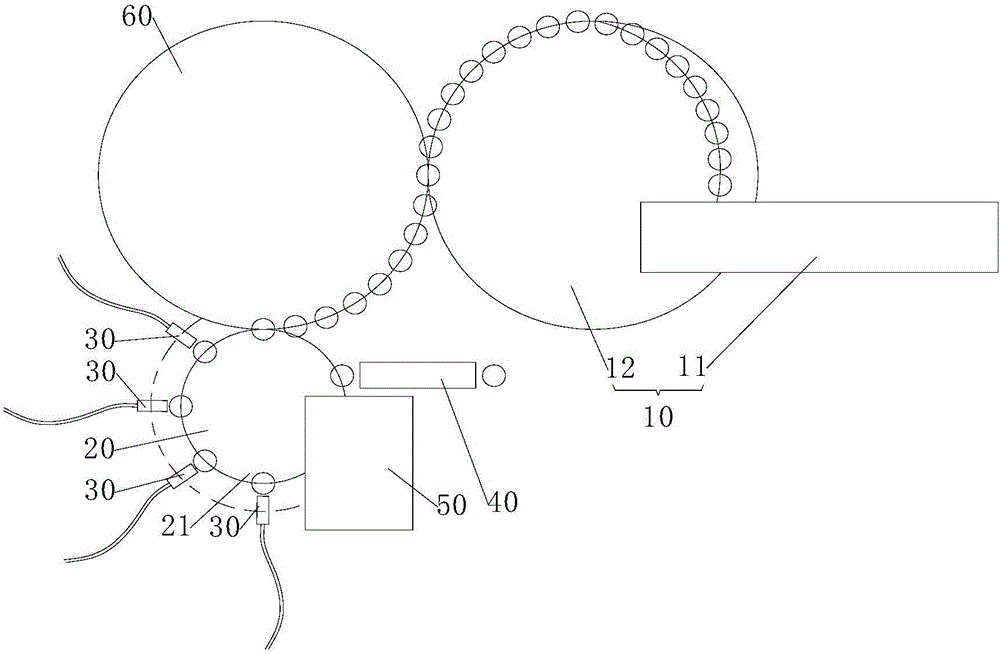

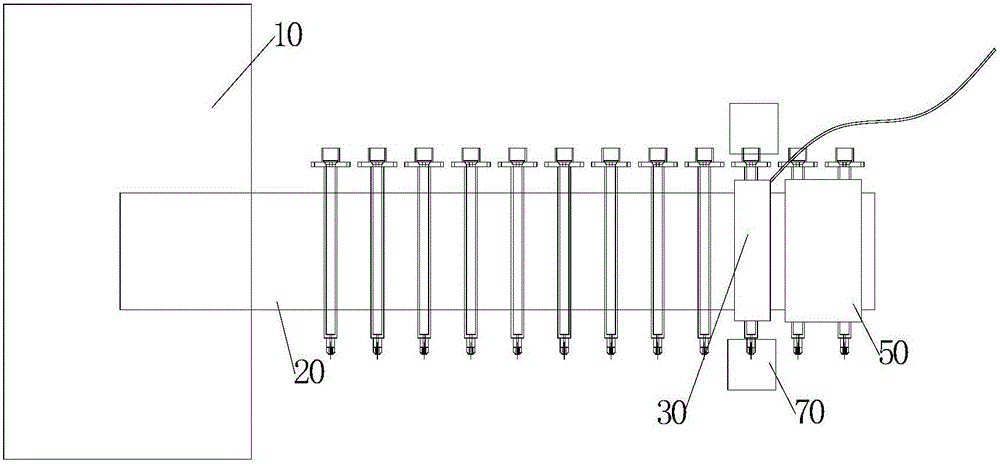

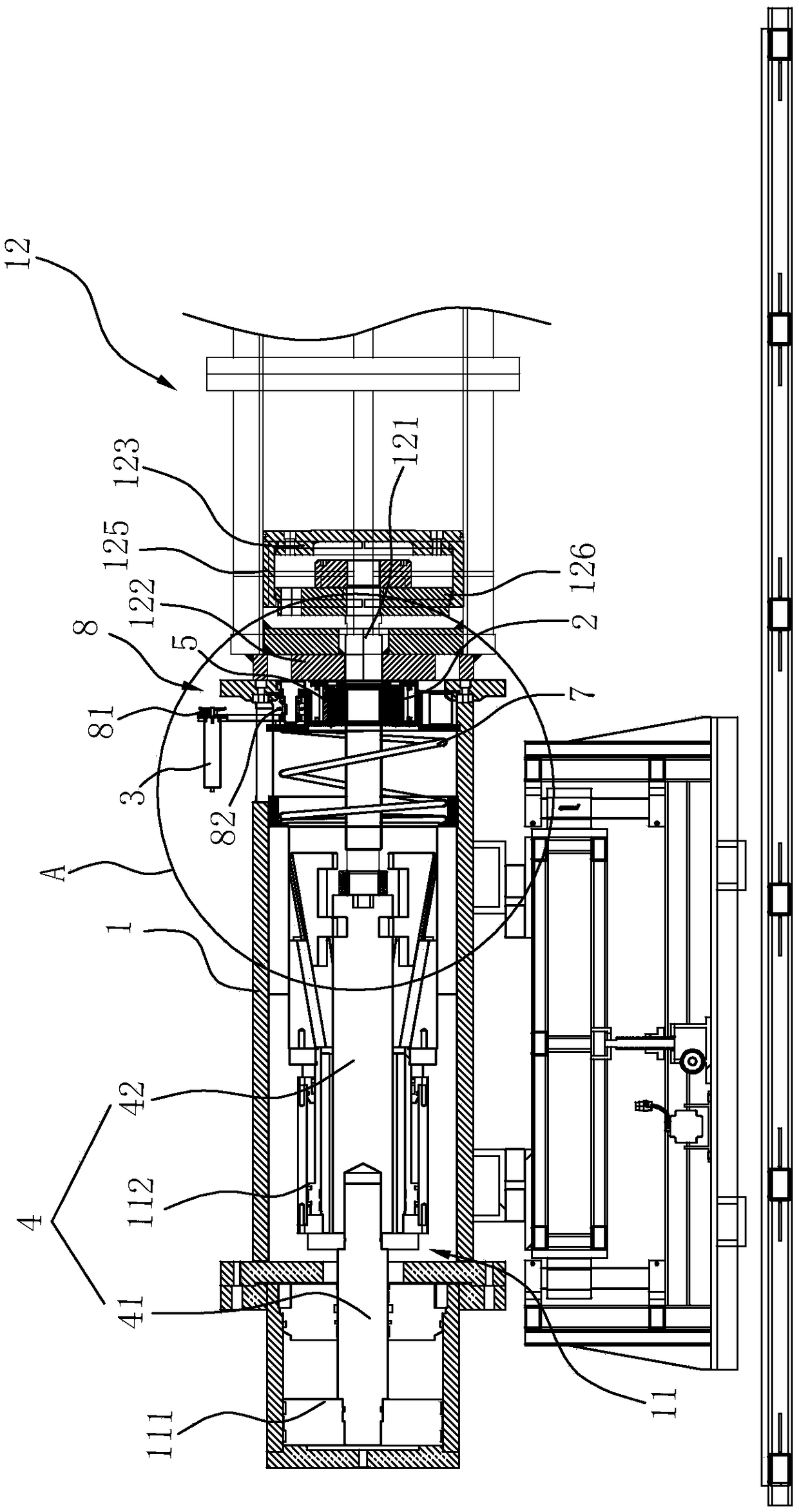

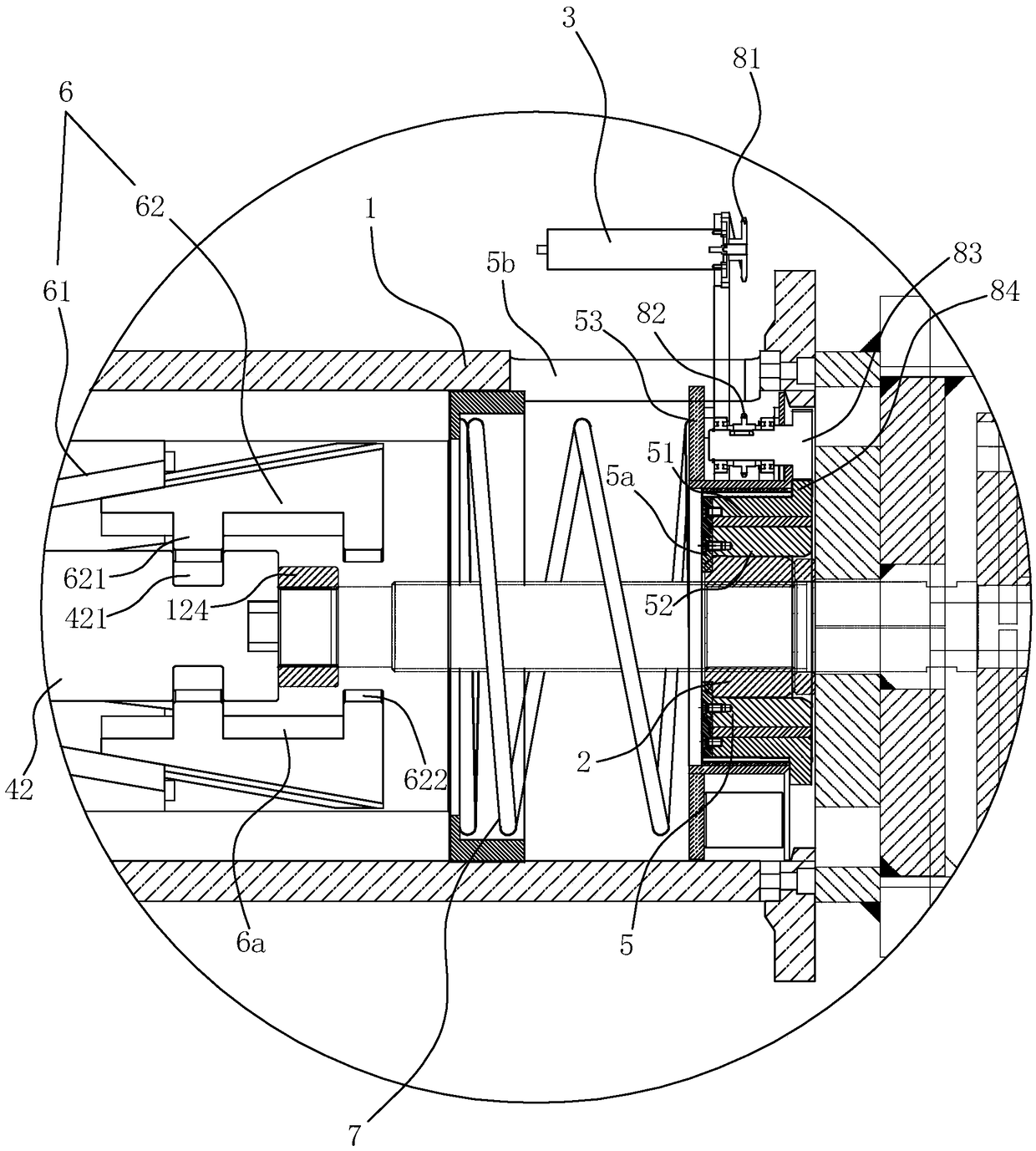

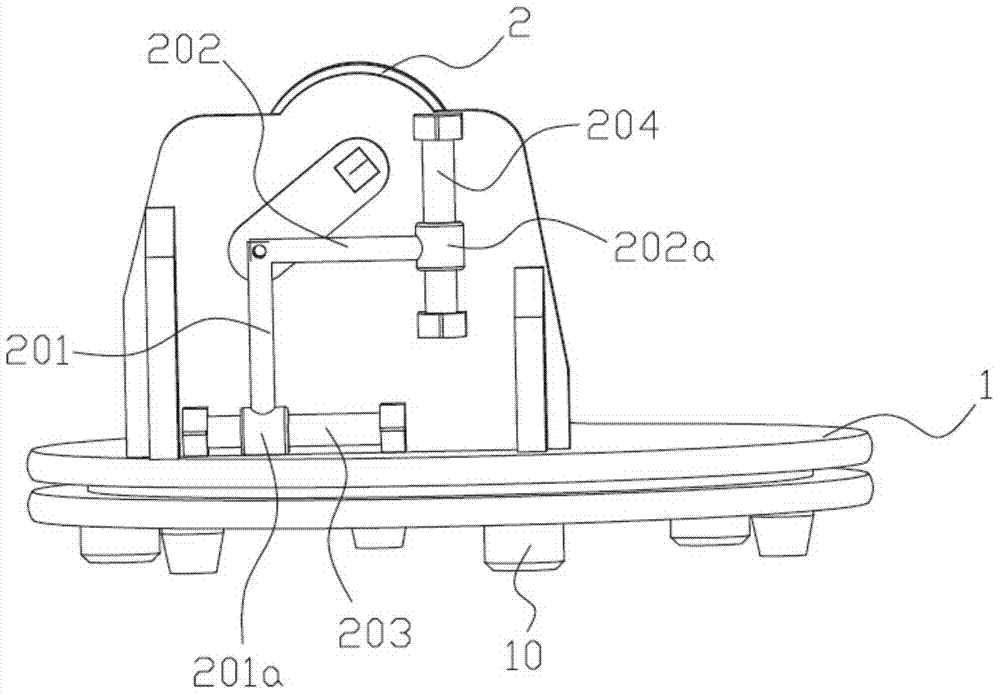

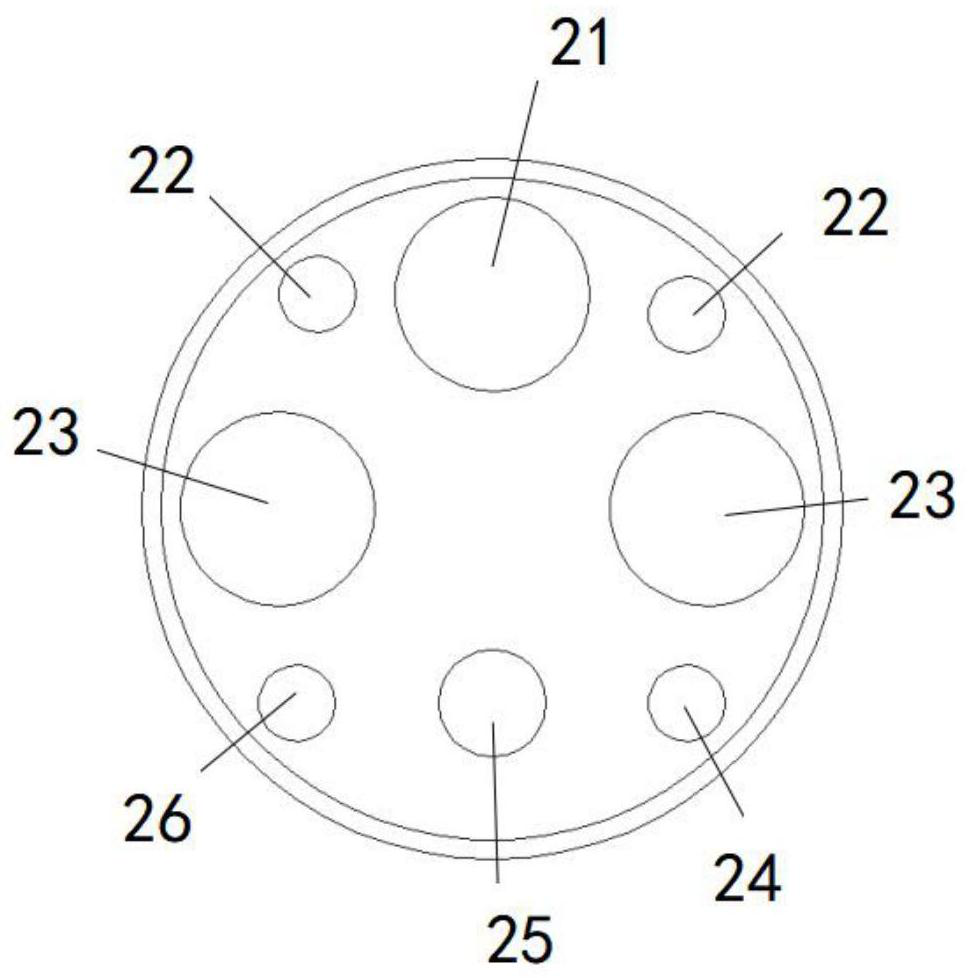

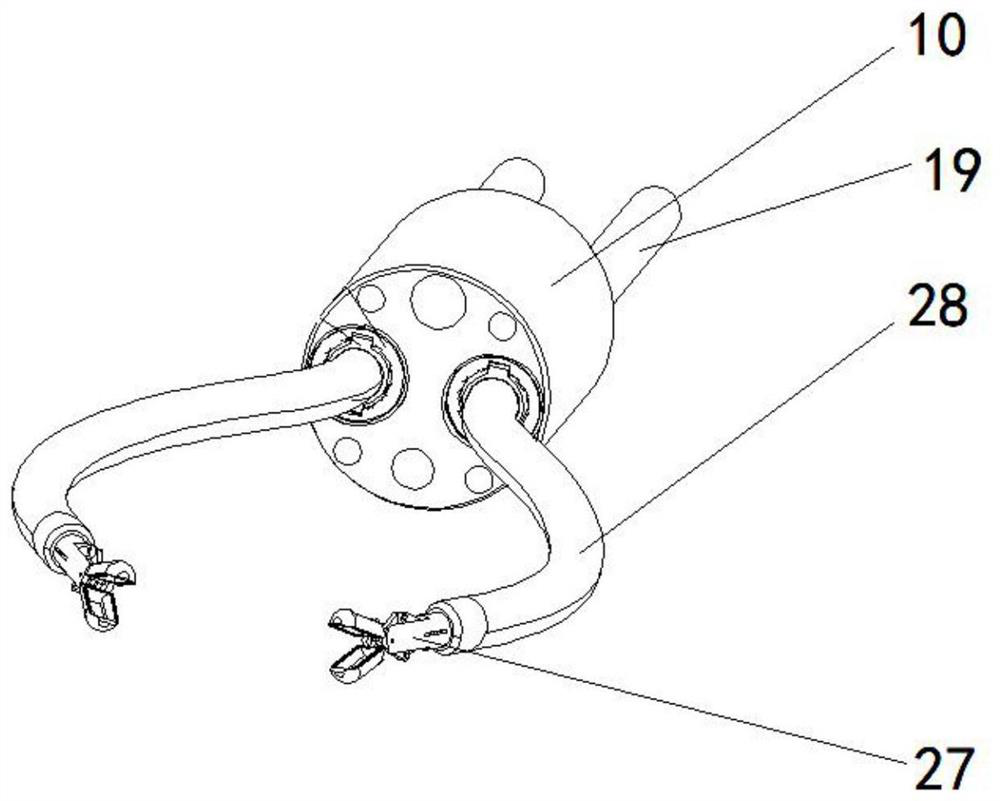

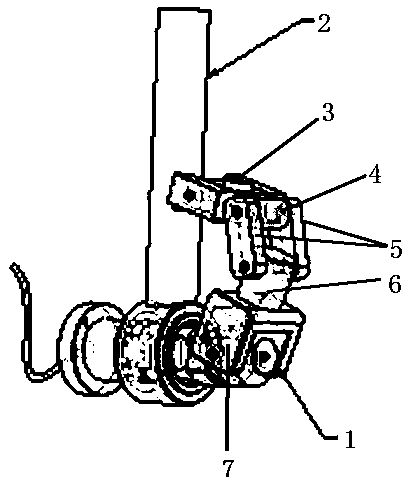

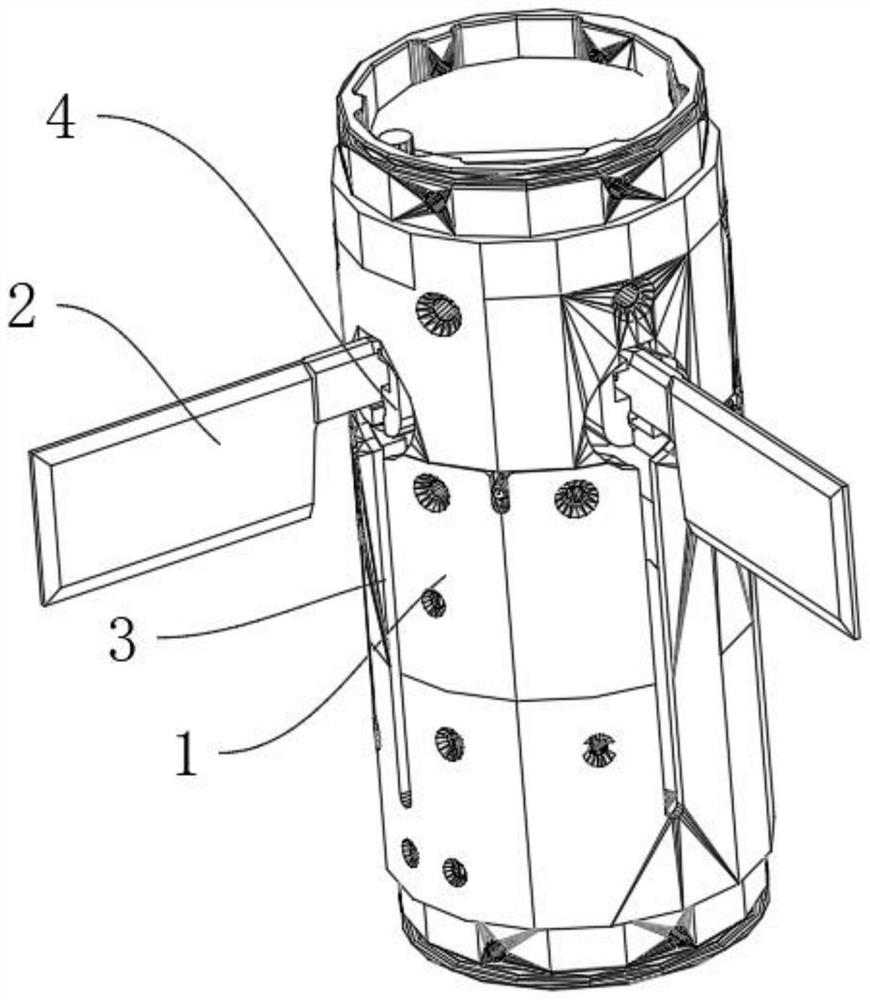

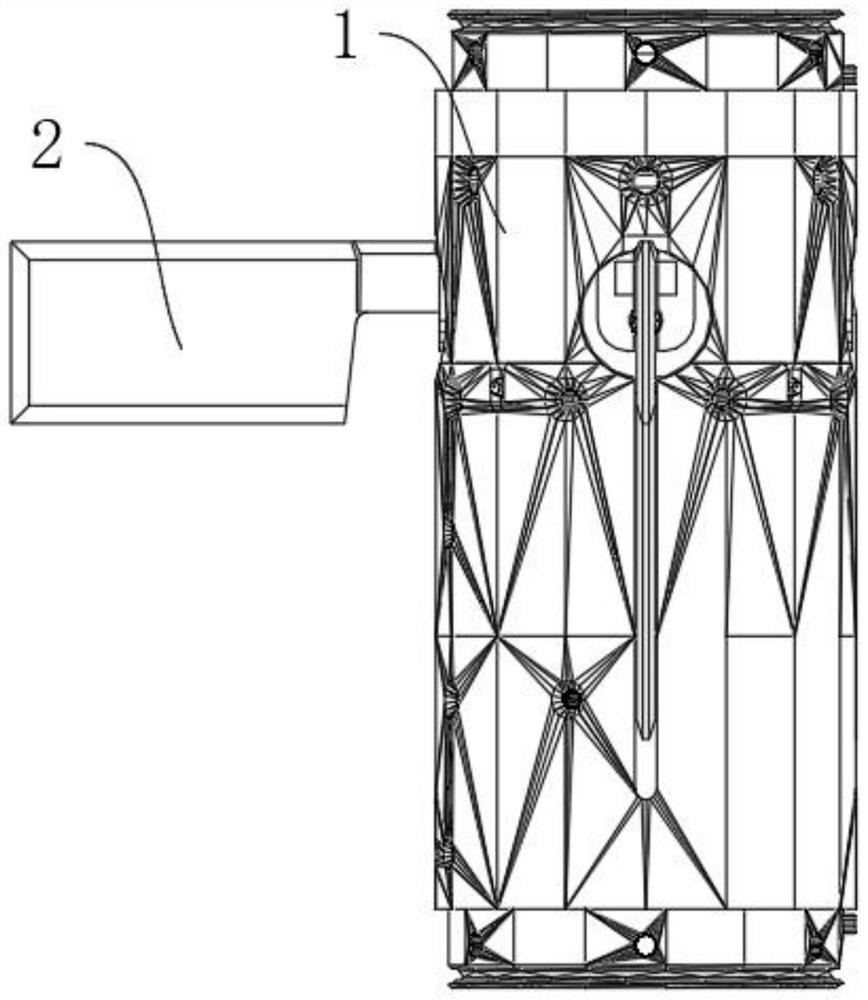

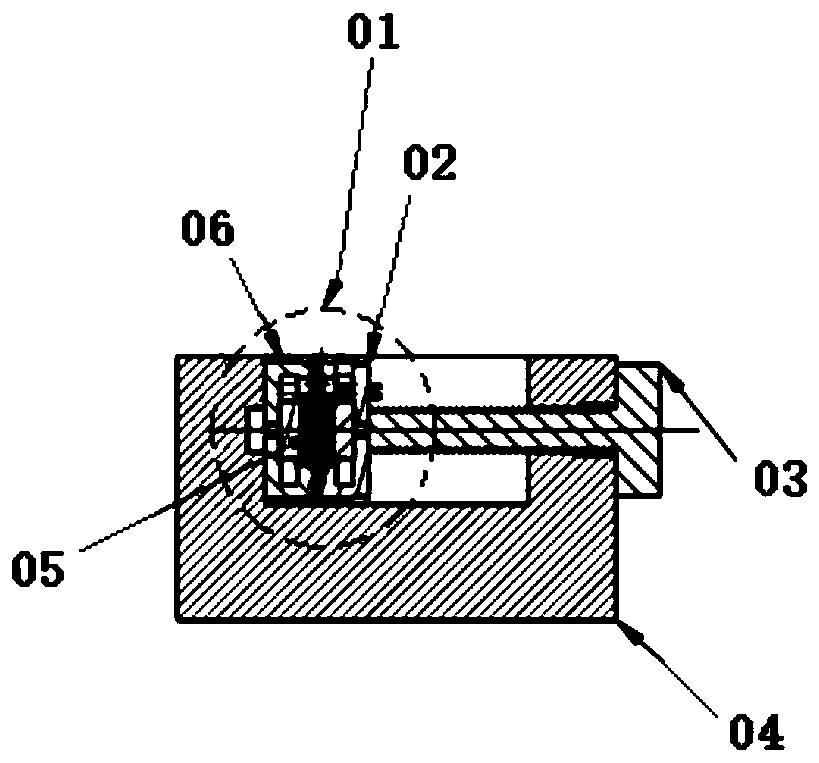

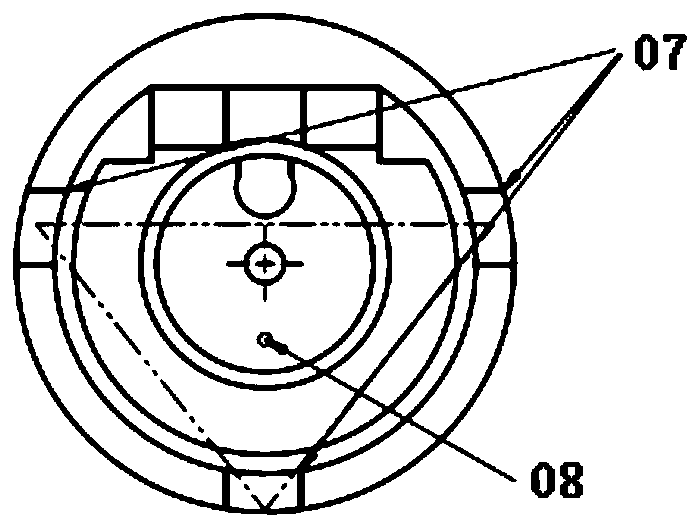

Track vehicle rim and tread flaw detection probe assembly system

ActiveCN103472138AEasy to useProtect the safety of useMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringManipulator

The invention discloses a track vehicle rim and tread flaw detection probe assembly system. The track vehicle rim and tread flaw detection probe assembly system comprises a tread flaw detection probe assembly and a rim flaw detection probe assembly. The tread flaw detection probe assembly leans on the tread of a wheel through a mechanical arm; the rim flaw detection probe assembly leans on the rim surface of the wheel through the mechanical arm; the tread flaw detection probe assembly can automatically detect wheel tread and rim defects from the tread in an online mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate; the rim flaw detection probe assembly can automatically detect wheel rim surface and tread detects from the inner lateral side of the rim in on online-mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate.

Owner:BEIJING SHEENLINE GRP CO LTD

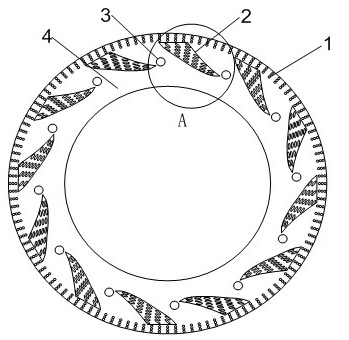

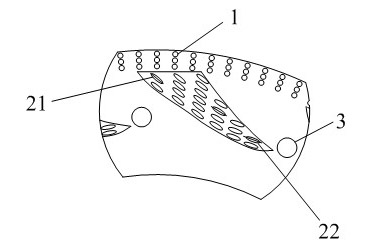

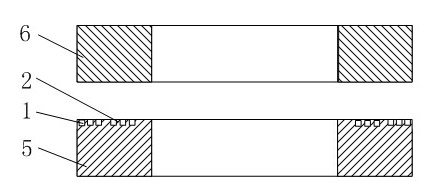

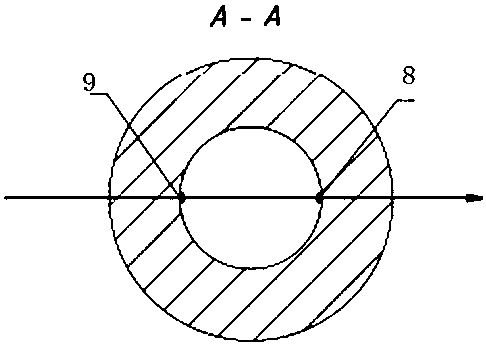

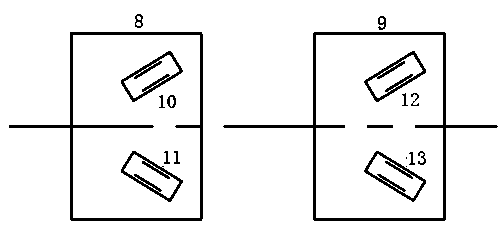

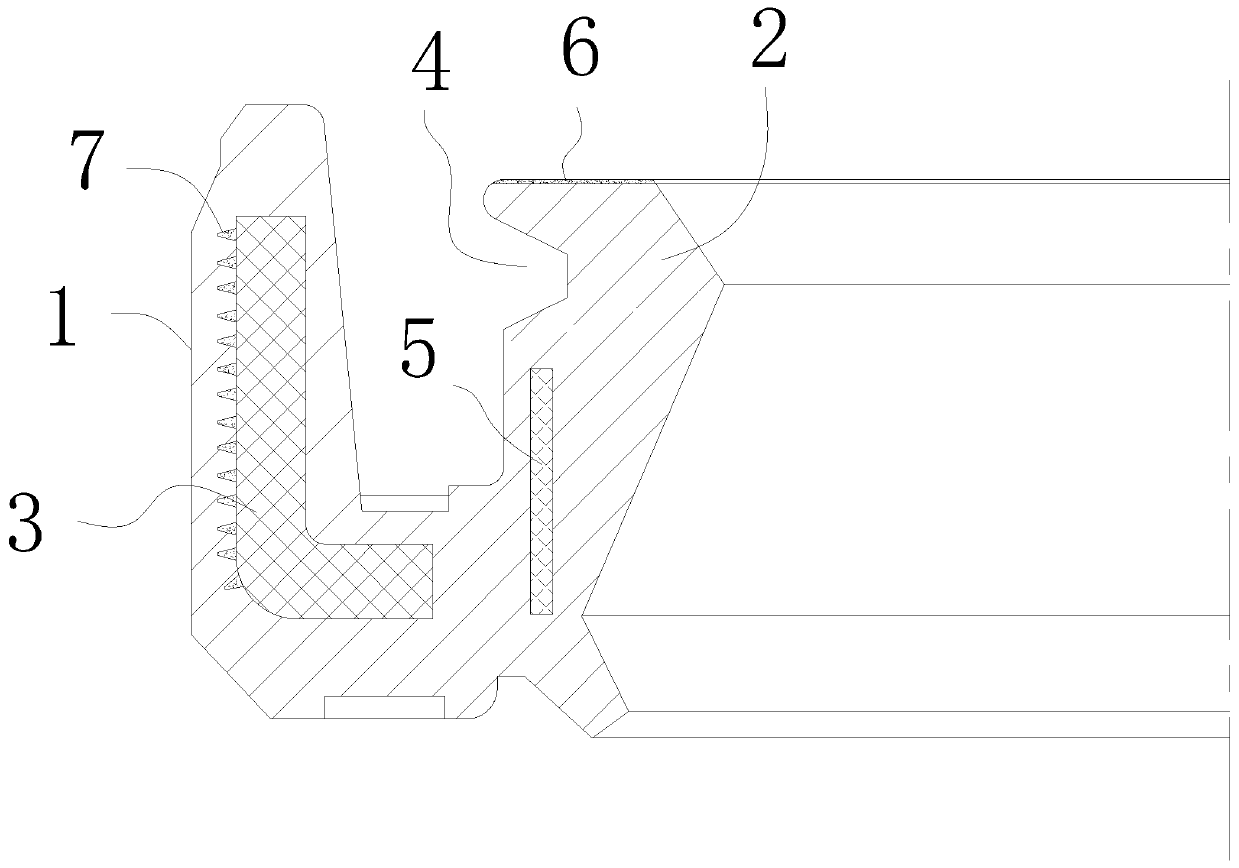

Negative pressure groove end face mechanical seal structure

The invention relates to a negative pressure groove end face mechanical seal structure, comprising a mechanically sealed moving ring and a mechanically sealed static ring, one side of the end faces of the moving ring and the static ring is a high pressure side namely upstream, the other side of the end faces of the moving ring and the static ring is a low pressure side namely downstream, at leastone end face of the moving ring or the static ring is provided with negative pressure groove groups which are symmetrically distributed with the center of rotation, the upstream of each negative pressure groove group is provided with a micropore annular band, each negative pressure groove group is composed of micropore dynamic pressure grooves with spiral deformation and inclination and relief grooves, the micropore dynamic pressure grooves and the relief grooves are distributed at intervals, the relief grooves are close to the terminals of the dynamic pressure grooves, and the downstream of each negative pressure groove group is provided with an annular sealing dam with a smooth plane. The invention has the beneficial effects of enhancing antijamming capability of sealing in operation athigh speed, improving dynamic pressure opening capability of a high speed seal face under the low speed working condition, realizing non-contact stability of the seal face under the high speed working condition, reducing end face contact wear, prolonging service life and improving sealing reliability.

Owner:海宁市黄湾镇资产经营有限公司

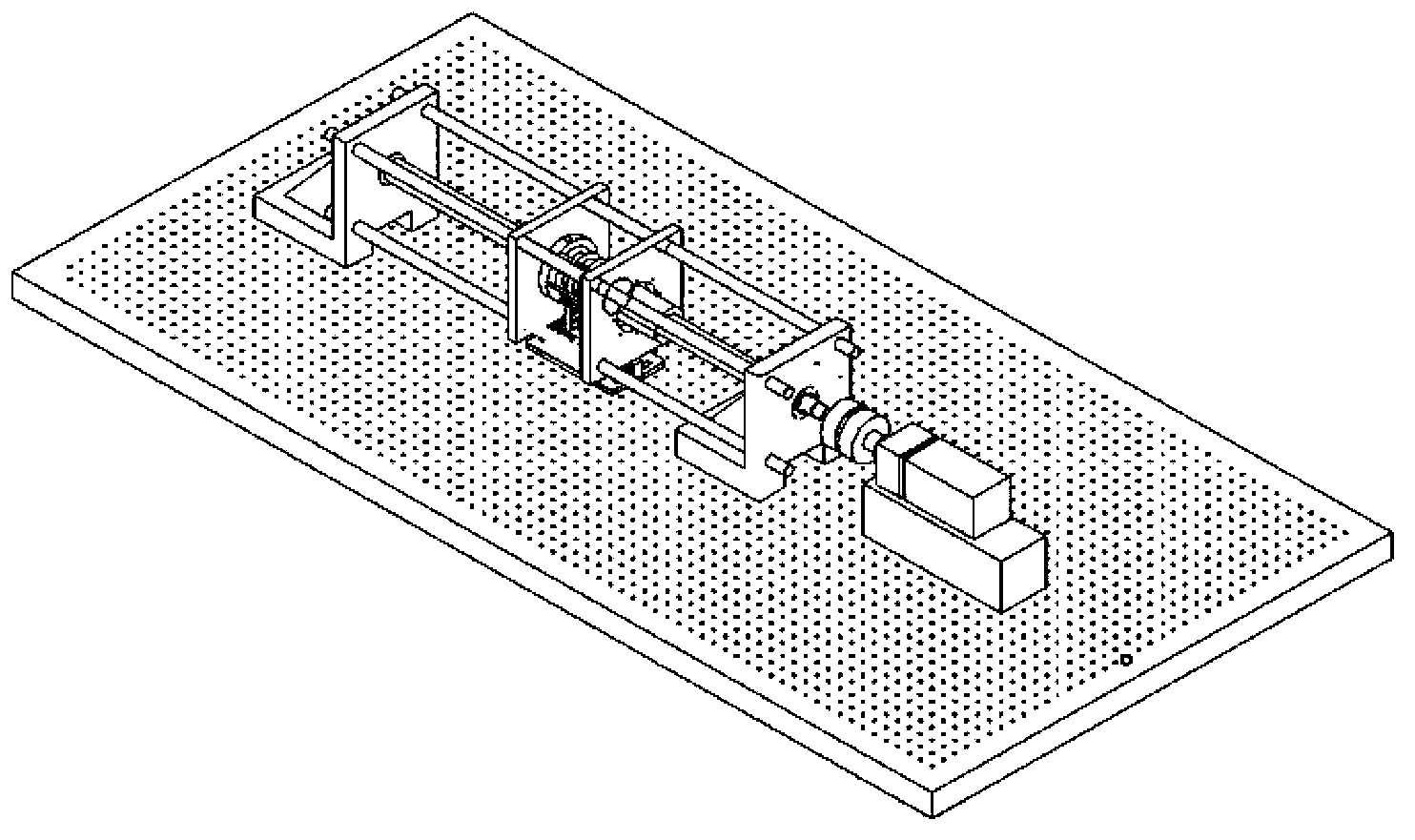

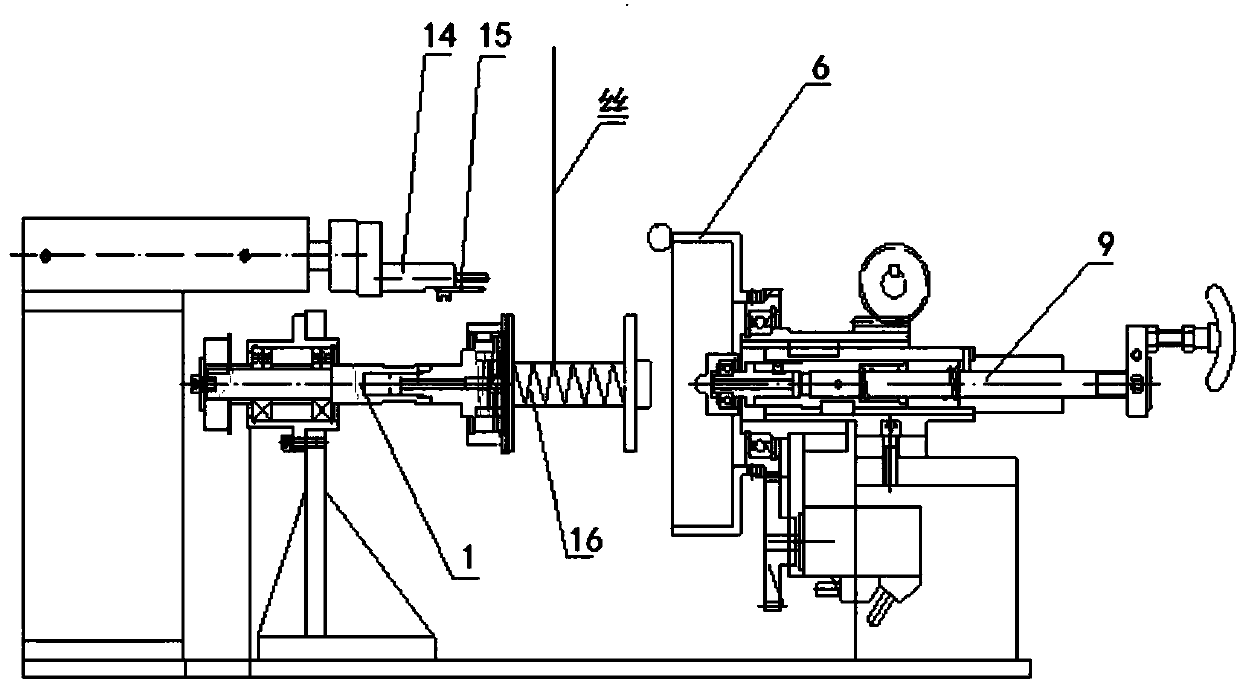

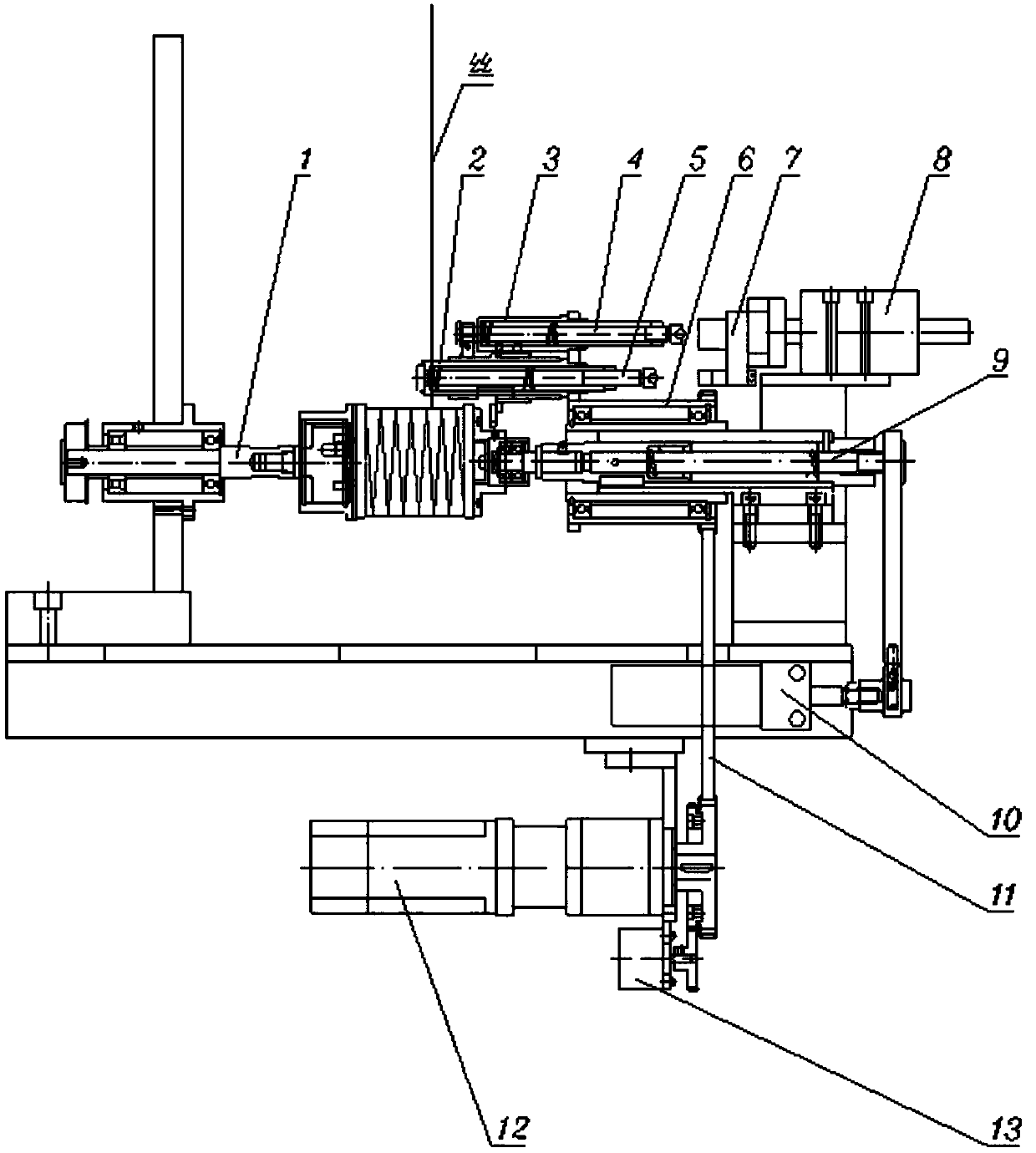

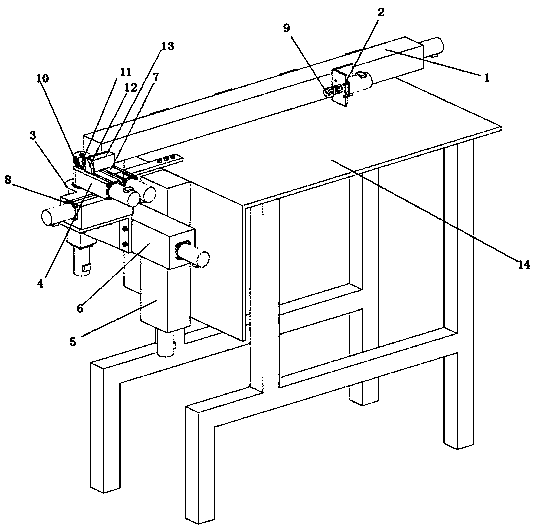

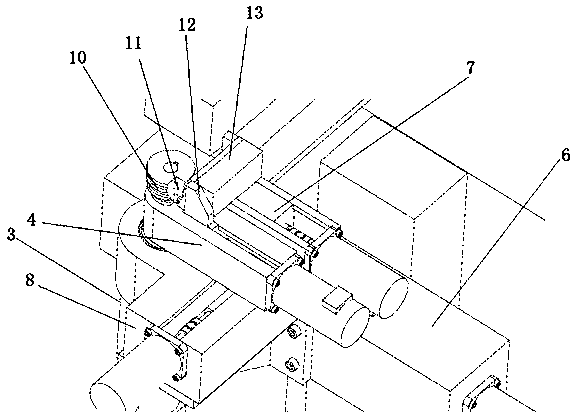

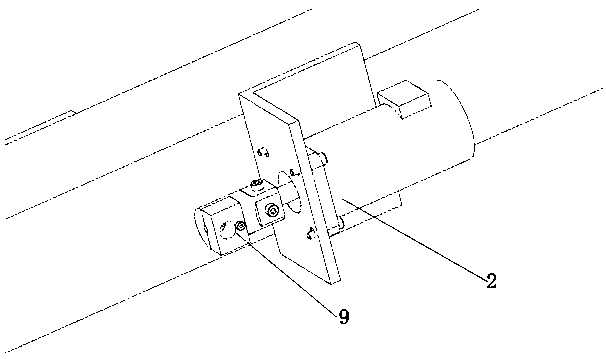

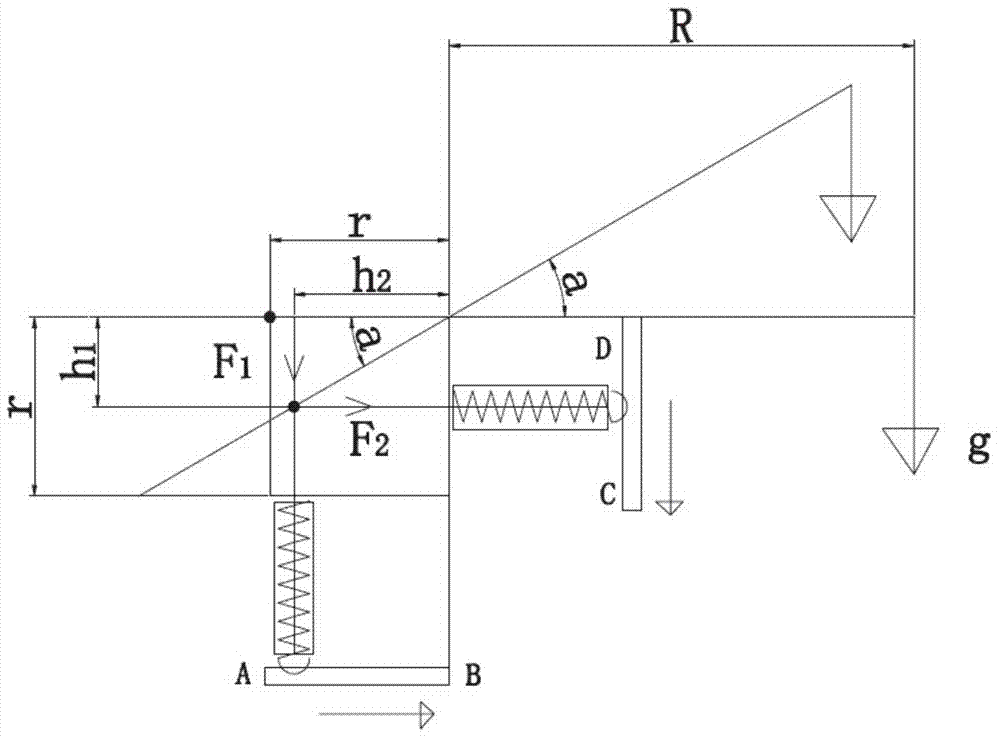

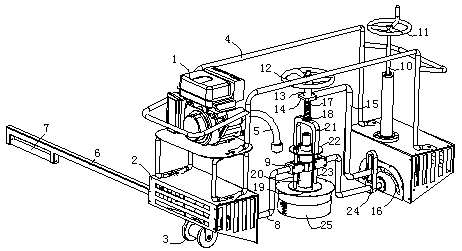

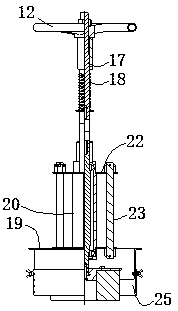

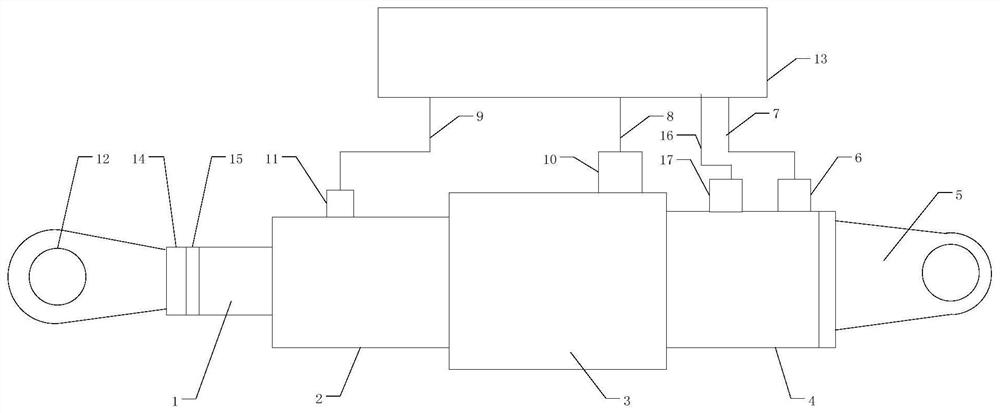

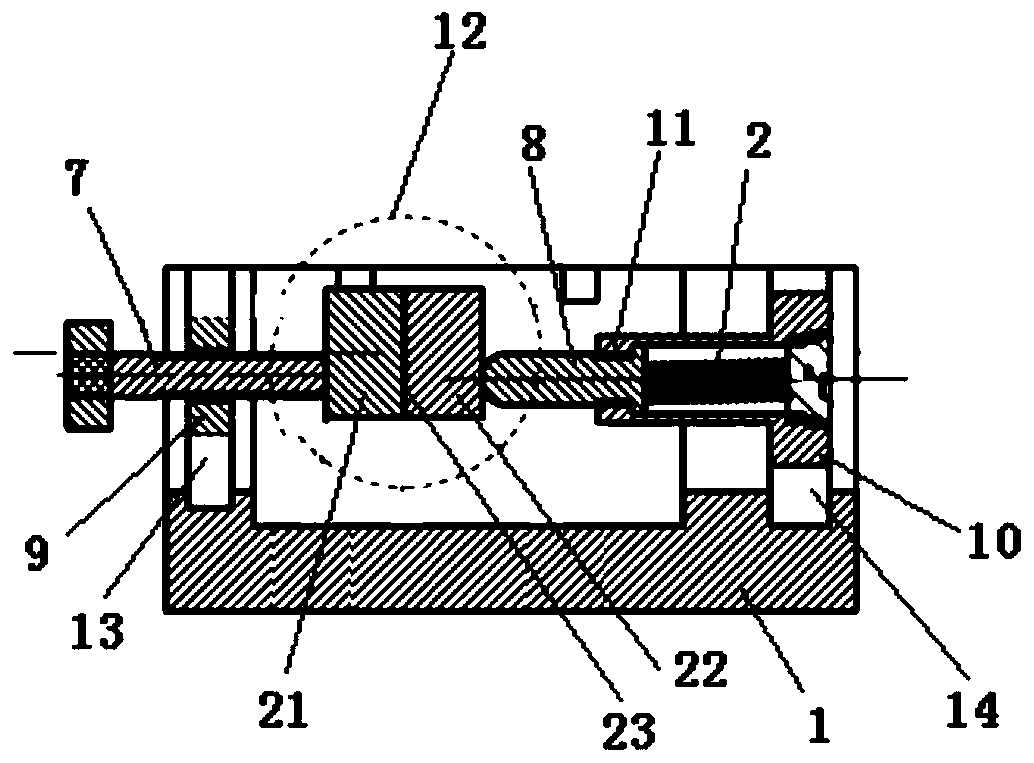

Friction force measuring device of ball screws with variable loads and measuring method of friction force measuring device

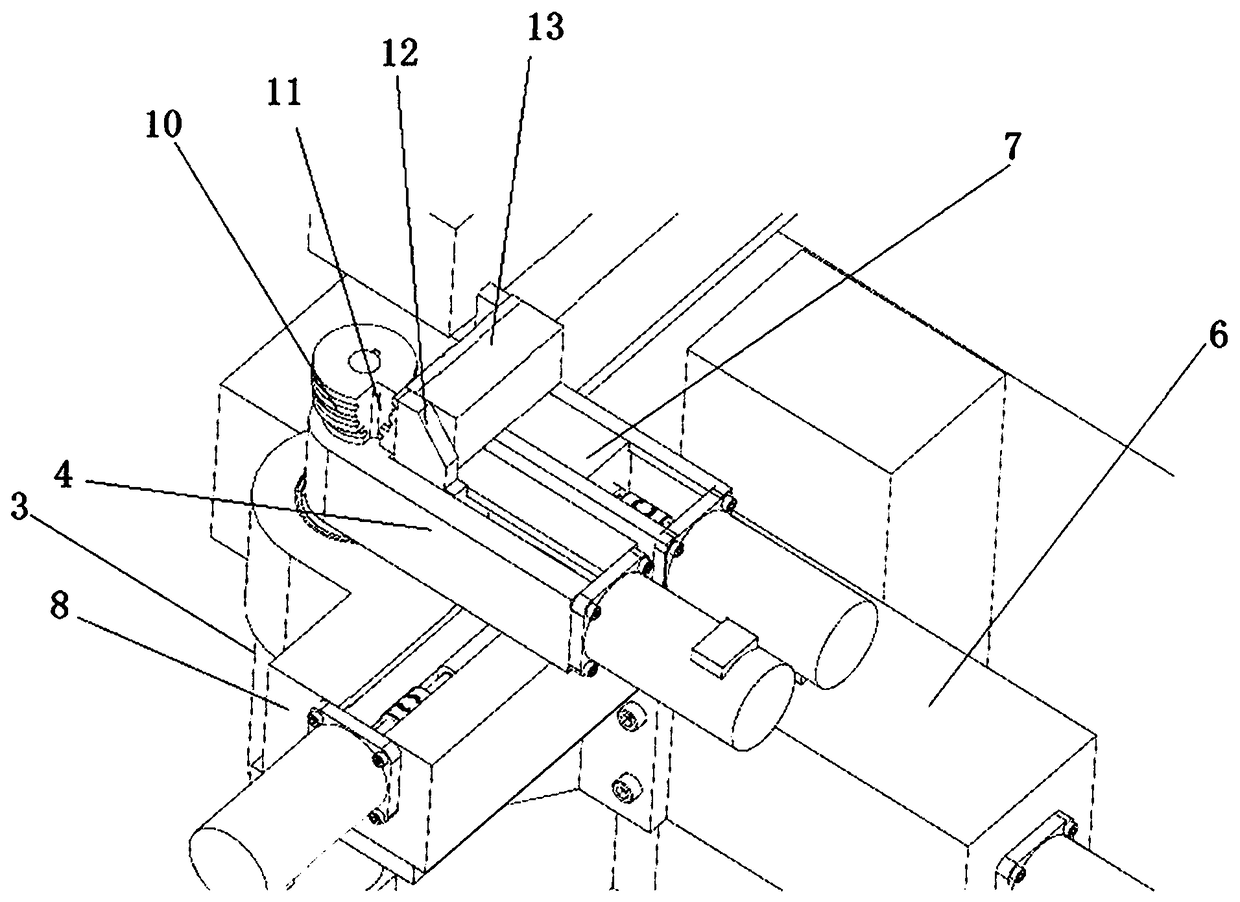

ActiveCN103175644AWill not affect the measurementGuaranteed follow-upApparatus for force/torque/work measurementBall screwSteel ball

The invention discloses a friction force measuring device of ball screws with variable loads. The friction force measuring device comprises a vibration insolating rack, an L-shaped base, a servo motor, a guide spline, a spring, a double-nut ball screw, a shaft coupler, a friction force measuring mechanism and the like. The friction force measuring mechanism comprises two baffles, ten bolts, ten steel balls, a dynamic sensor, a sensor support and a dowel bar. The L-shaped base is fixed on the vibration insolating rack; the ball screw is set up on the L-shaped base with one end fixed and the other end free; the spring is mounted between two nuts; and the measuring device is placed on the guide spline. The invention further provides a corresponding measuring method of the friction force measuring device. Quantificational varying of axial loads of the ball screws can be realized by the aid of the friction force measuring device with internal loads which are remarkably different from that of other operation devices, so that affections of other friction force caused by external loads do not exist, and friction force between rolling bodies of the ball screws and a rolling path can be measured accurately.

Owner:SHANGHAI JIAO TONG UNIV

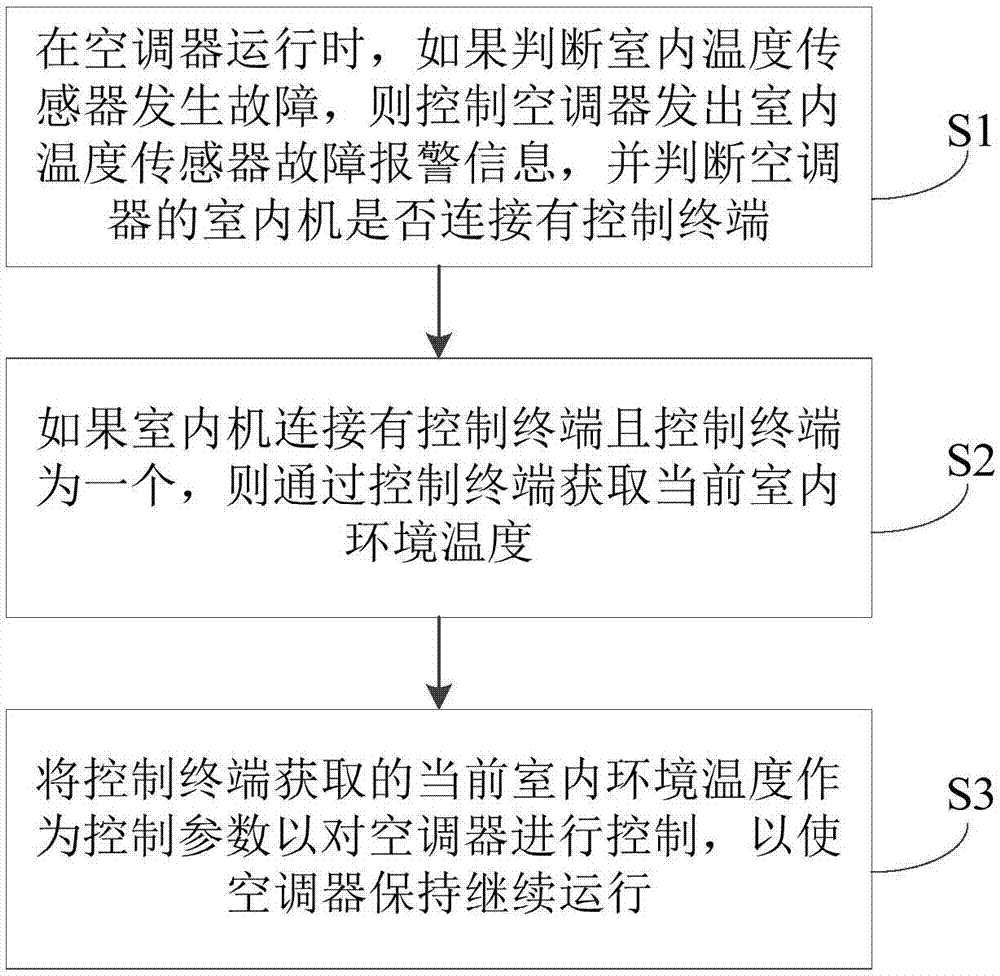

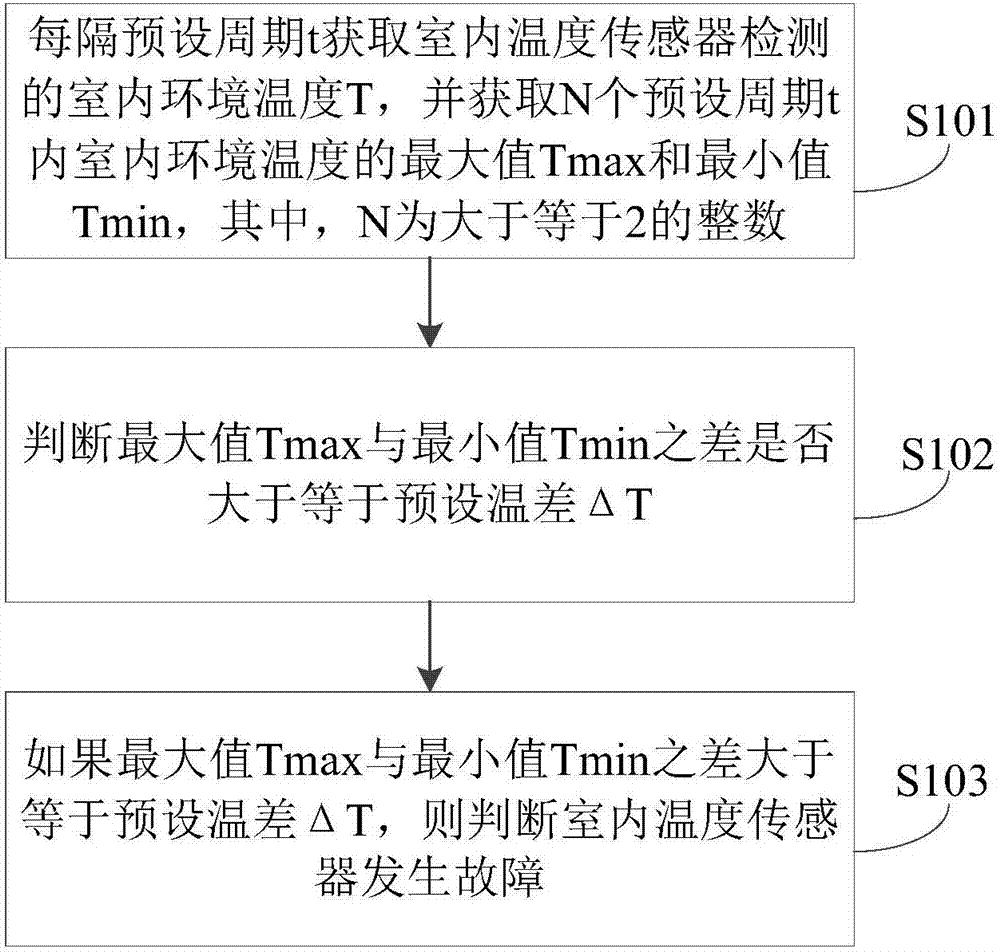

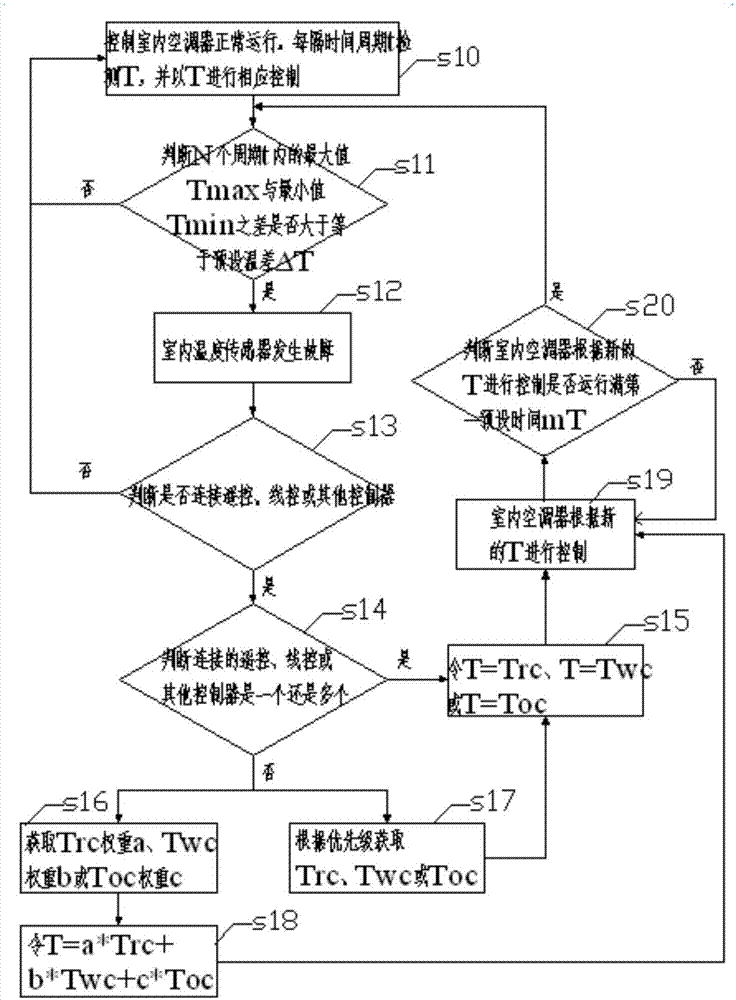

Air conditioner, control method and device thereof and computer readable storage medium

InactiveCN107166678AGuaranteed uptimeImprove experienceMechanical apparatusSpace heating and ventilation safety systemsComputer terminalControl parameters

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Automatic knotting device of full-automatic doubling mechanism

The invention relates to an automatic knotting device of a full-automatic doubling machine. A wire winding mechanism, a wire clamping mechanism, a wire pushing mechanism and a knotting driving deviceare included. The wire winding mechanism comprises a wire winding disc. The wire clamping mechanism comprises a wire clamping rod and a first sleeve. The wire pushing mechanism comprises a wire pushing rod and a second sleeve. One end of the wire clamping rod is provided with a first positioning block and positioned at the end portion of the first sleeve through the first positioning block. One end of the wire pushing rod is provided with a second positioning block and positioned at the end portion of the second sleeve through the second positioning block. A first elastic component is arrangedin the first sleeve, a second elastic component is arranged in the second sleeve, the wire clamping rod is used for conducting telescopic movement in the first sleeve through the first elastic component, and the wire pushing rod is used for conducting telescopic movement in the second sleeve through the second elastic component. The automatic knotting device is high in knotting success rate, a wire hooking mechanism is omitted, and the problems that an existing full-automatic doubling machine is low in automatic knotting success rate and large in occupied space, and machining and assembling are difficult are solved.

Owner:SHANGHAI NANYANG ELECTRICAL EQUIP

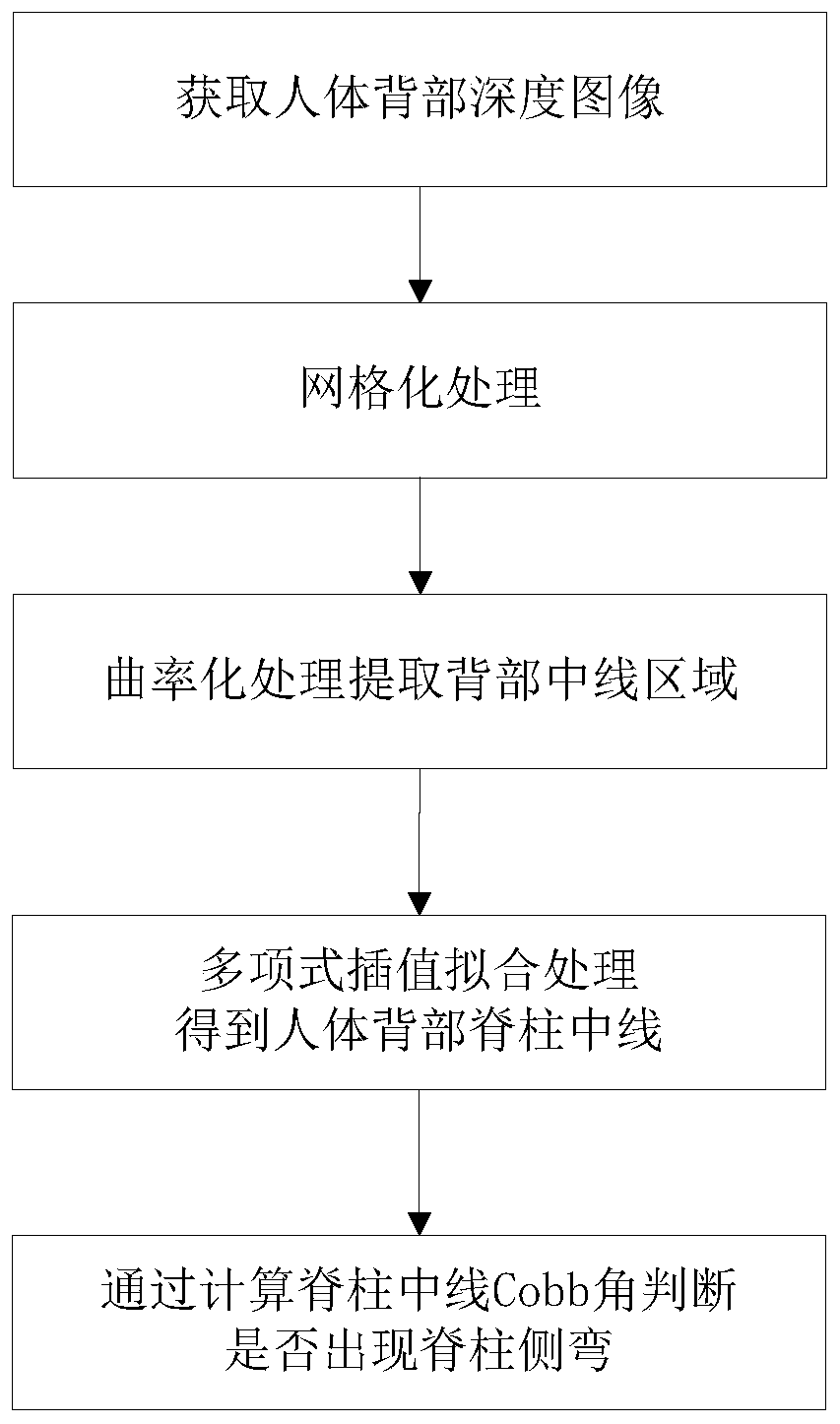

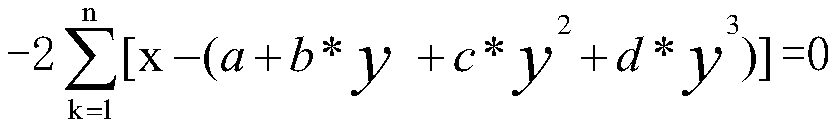

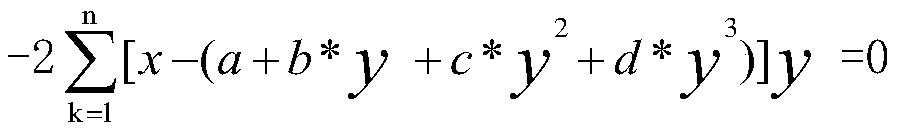

A scoliosis detection method based on polynomial curve fitting

InactiveCN109903277AGuaranteed follow-upConditions that Affect AccuracyImage analysisMachine visionCurve fitting

The invention discloses a scoliosis detection and recognition method based on polynomial curve fitting. The method comprises the steps that a machine vision scheme is used for automatically extractingthe center line of a back spine, curve fitting is conducted in combination with back feature points, and cobb angle calculation is conducted. According to the method, the spine center line of a person can be efficiently and accurately obtained through the depth camera, cobb angle calculation is carried out on the spine center line to carry out lateral bending judgment, the labor intensity of manual detection is greatly reduced, and the diagnosis precision is improved. Through cubic polynomial fitting, subsequent processing of the data can be ensured, the situation that higher-order polynomialfitting generates oscillation in actual use and affects the data precision is avoided, and a guarantee is provided for the accuracy of the data.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Stainless steel sand mold casting process

InactiveCN104338899AGuaranteed follow-upGuaranteed processing efficiencyFoundry mouldsMoulding machinesSS - Stainless steelLiquid steel

The invention relates to the technical field of casting processes, and particularly relates to a stainless steel sand mold casting process. The process specifically comprises the following steps: making a mold; producing product models; finely trimming the models; assembling and splicing inner and outer models; heating liquid steel in a casting furnace; breaking the outermost layer and an inner core sand shell into pieces after the liquid stainless steel is cooled and solidified; emptying the inner core sand shell to expose a solid stainless steel product; cutting and separating the product one by one, and then roughly grinding the product to form a simplex blank part; slinging; inspecting the blank; washing the blank; performing other working procedures until a finished product is obtained. The process disclosed by the invention can solve the problem of production of the stainless steel product which is strange in shape and cannot be produced by using processes such as pipe bending and welding; the production process can enable the processing capacity of each product to be minimized, and an inner chamber is totally finished according to the requirements of a product design, so that the subsequent processing and the processing efficiency of the product are guaranteed, the production efficiency is maximized, the production cost is lowered, the production efficiency is improved, and the brightness and the toughness of the produced product are both further improved.

Owner:黄旭伟

Quick living paris polyphylla tuber tillering and propagation technology

InactiveCN104620805AEfficient accumulationReduce dosageCultivating equipmentsPlant cultivationBiotechnologyPlantlet

The invention relates to a quick traditional Chinese medicinal material paris polyphylla propagation technology, in particular to quick living paris polyphylla tuber tillering and propagation technology. The technology solves the problems that in the prior art, the (seeds, slices and tissue culturing) seedling reproduction rate is low, the seedling emergence speed is low, and a great number of tubers are consumed. The quick living paris polyphylla tuber tillering and propagation technology mainly includes the following steps of (1) paris polyphylla female parent selection, (2) topdressing, (3) growing point priming, (4) terminal bud healing and transplant and (5) seedling emergence and transplant. According to the method, quick tillering and propagation are conducted on living paris polyphylla tubers, under the condition that the living tubers are not destroyed, and the living paris polyphylla tubers are promoted to generate multi-point germination by interdicting the original growing points of plants through a biological principle.

Owner:镇沅圣元堂生物科技开发有限责任公司

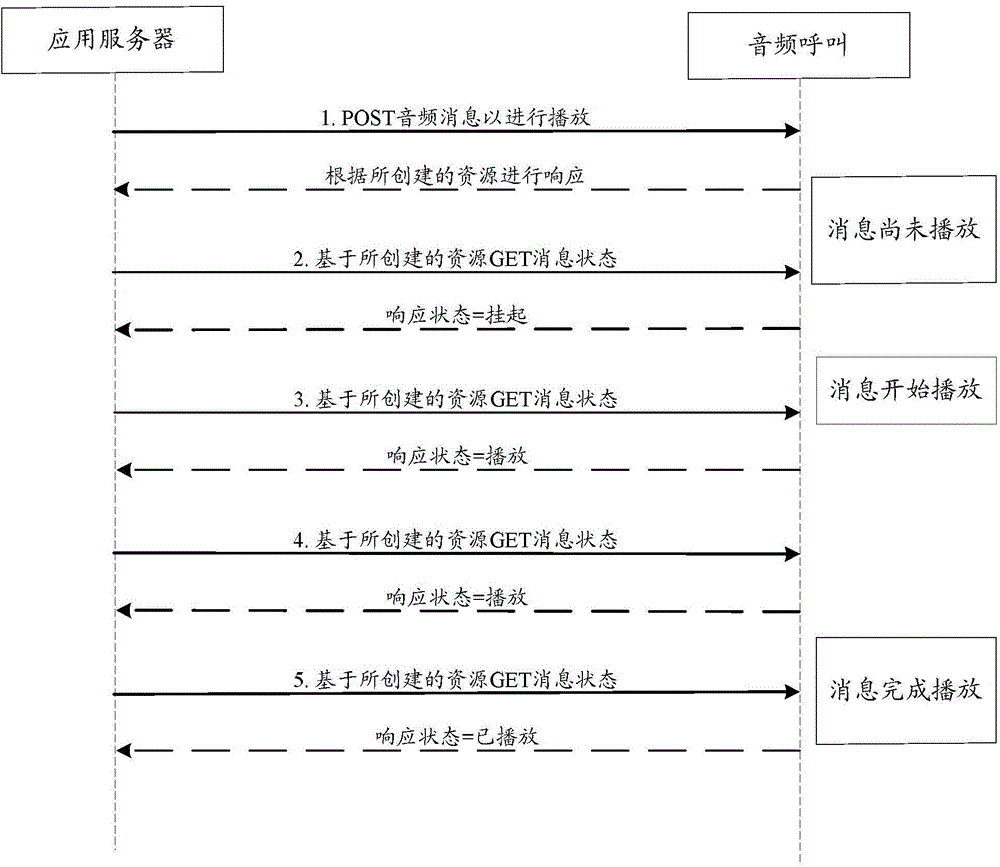

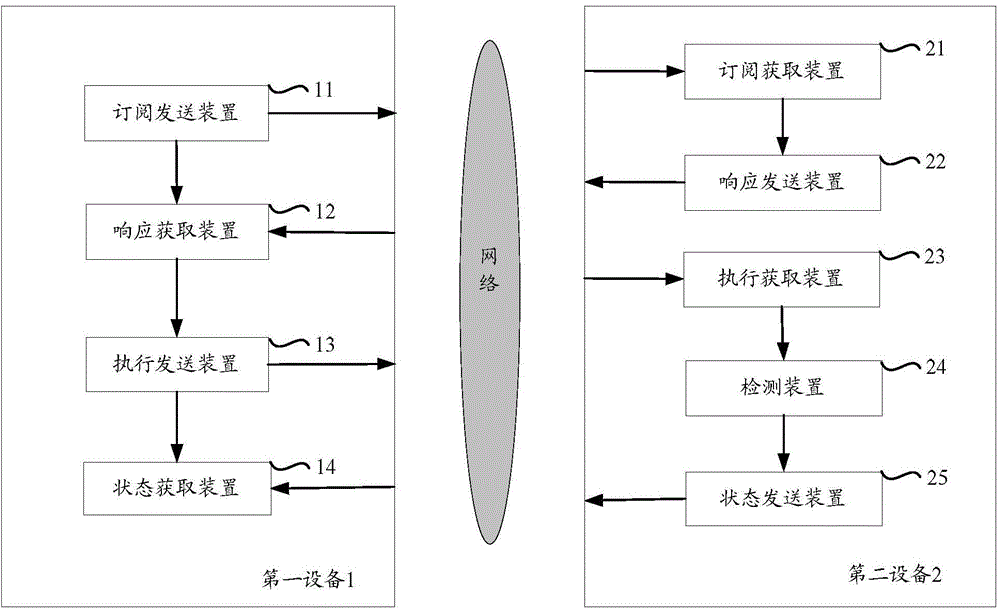

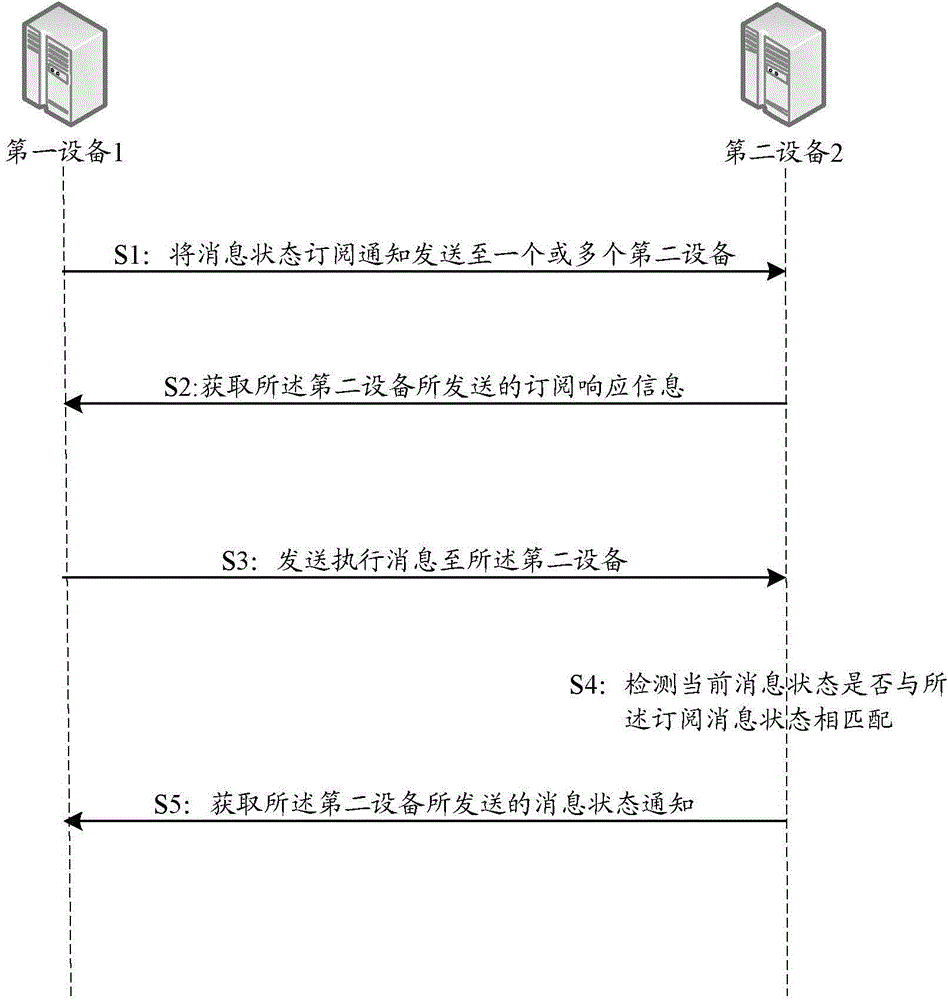

Method, devices and system for acquiring HTTP message status

InactiveCN106161196AImprove processing efficiencyAvoid delayData switching networksInformation processingResource identifier

The purpose of the invention is to provide a method, devices and a system for acquiring the HTTP message status. A first device sends a message status subscription notice to one or more second devices, and acquires subscription response information sent by the second device(s); then, the first device sends an execution message to the second device(s) based on a resource identifier in the subscription response information; and finally, when the message status notice matches the subscription message status, the first device acquires a message status notice sent by the second device(s). Compared with the prior art, the message status of the second device(s) is acquired by the first device in real time, message status delay is avoided, the efficiency of information processing is improved, the waste of resources is reduced, and the user experience is improved.

Owner:ALCATEL LUCENT SAS

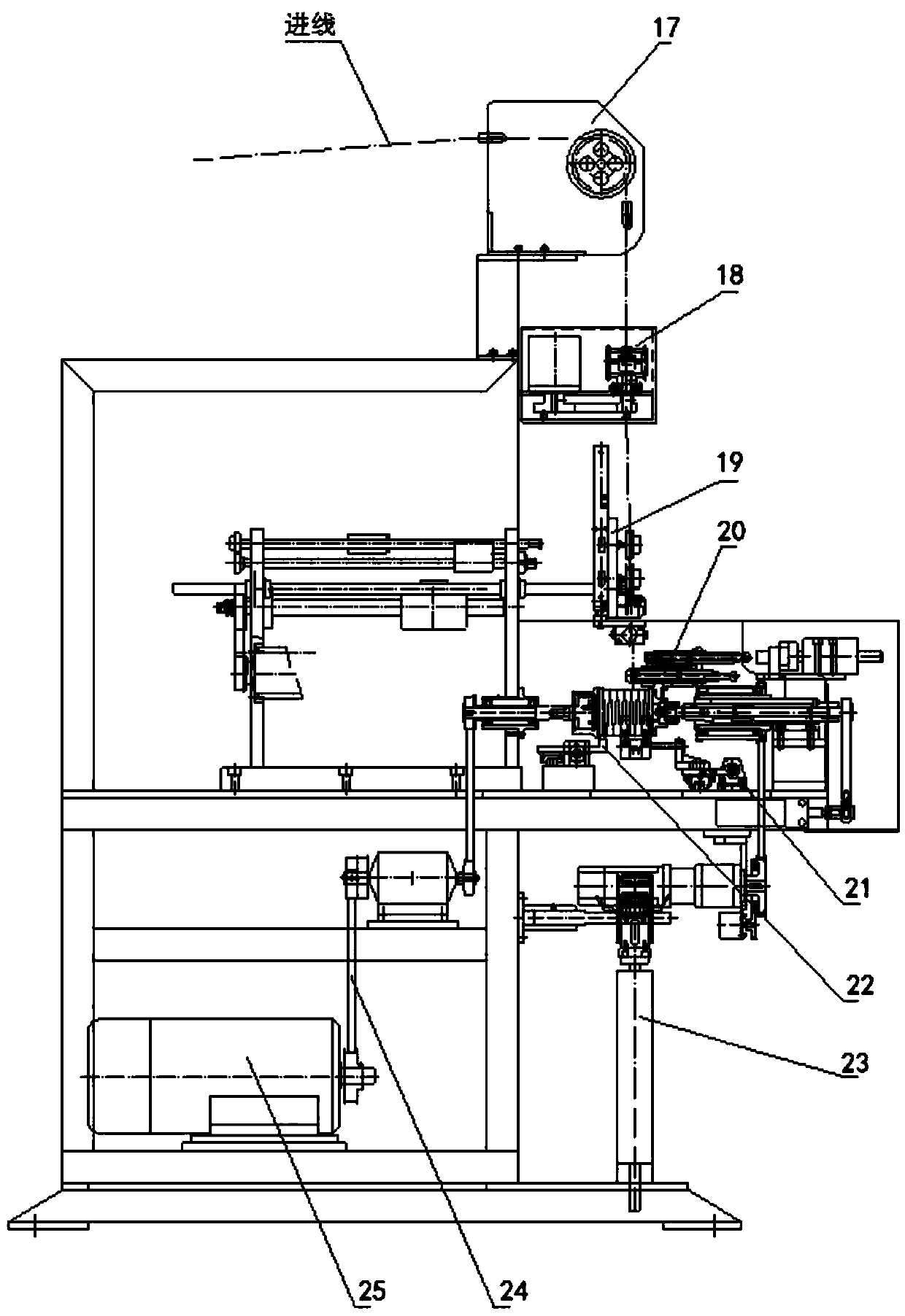

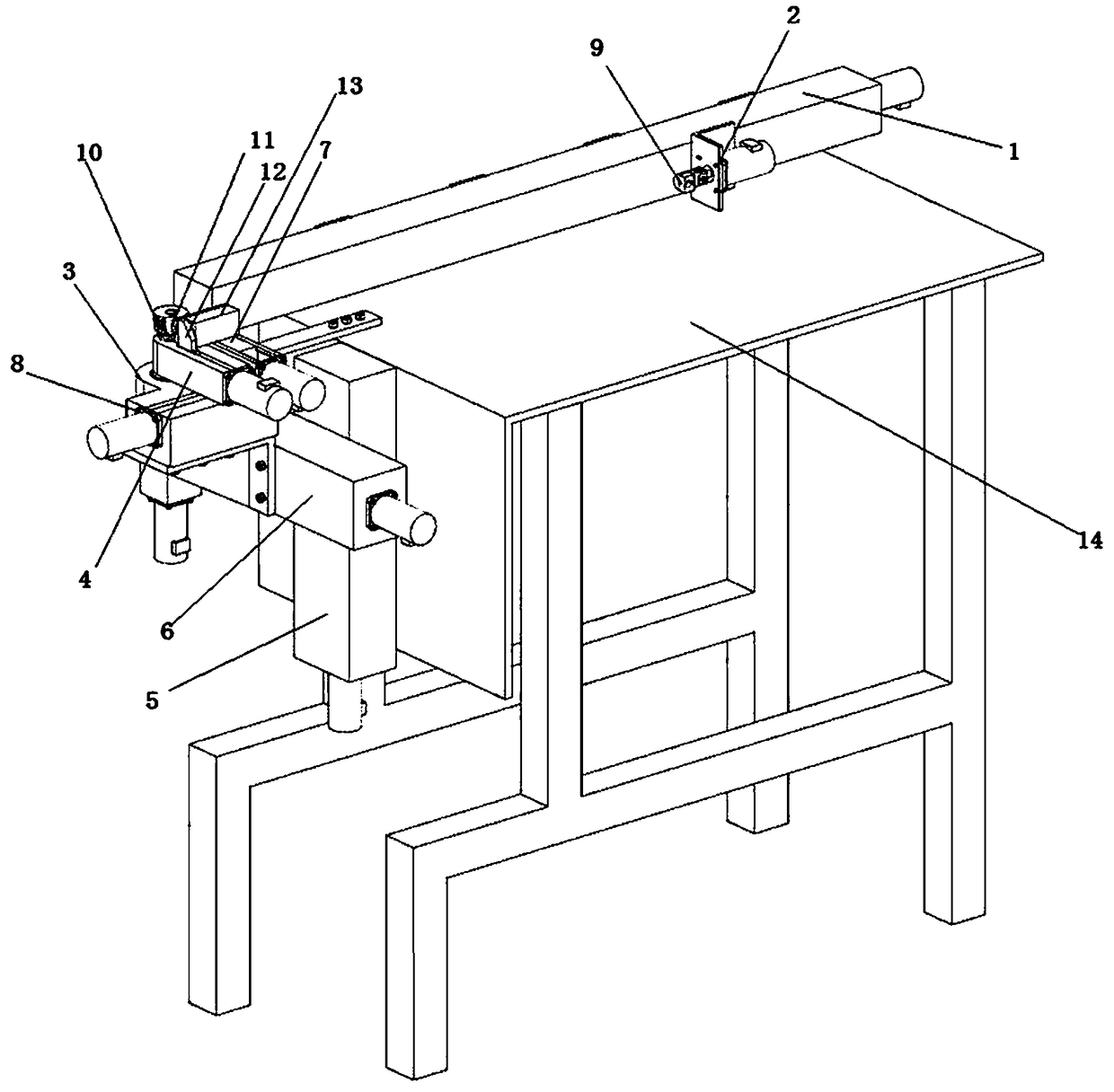

Full-servo numerical control pipe bending machine

InactiveCN109108120AEnsure consistencyReduce mistakesMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention discloses a full-servo numerical control pipe bending machine, and relates to the technical field of pipe bending processing. The device comprises a feeding mechanism, an angle rotatingmechanism, a pipe bending mechanism, a clamping mechanism, a lifting mechanism, a horizontal moving mechanism, a backup plate mechanism and a servo mechanism. According to the pipe bending machine, 8-axis servo control is adopted to complete the movement of different angles and positions, bending machining of any angle and radius can be realized, and machining precision is guaranteed; and meanwhile, a pipe bending die and a feeding clamp can be quickly replaced on the structure, so that the pipe bending machine has a function of welding before bending.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

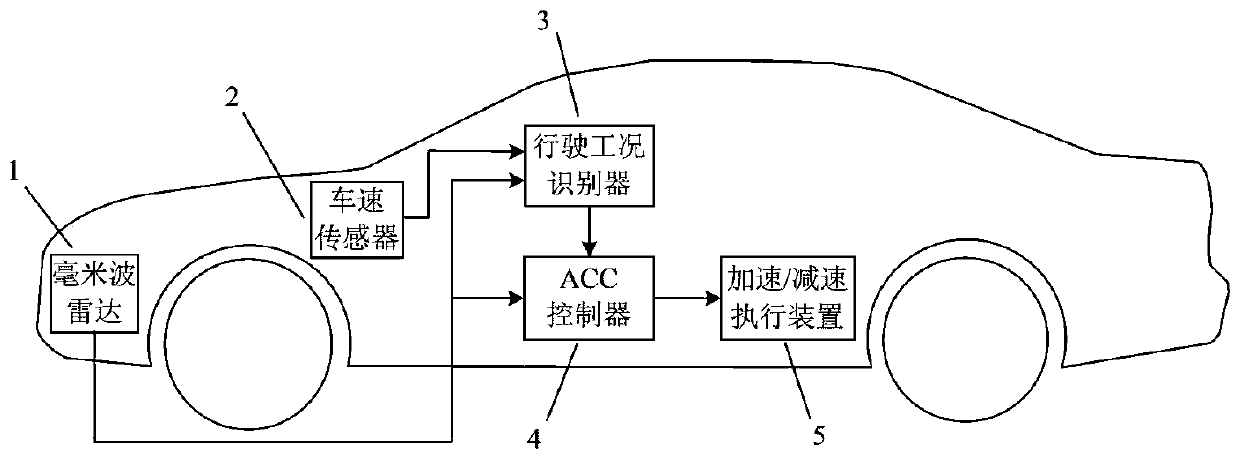

Economical adaptive cruise control system and method suitable for various driving conditions

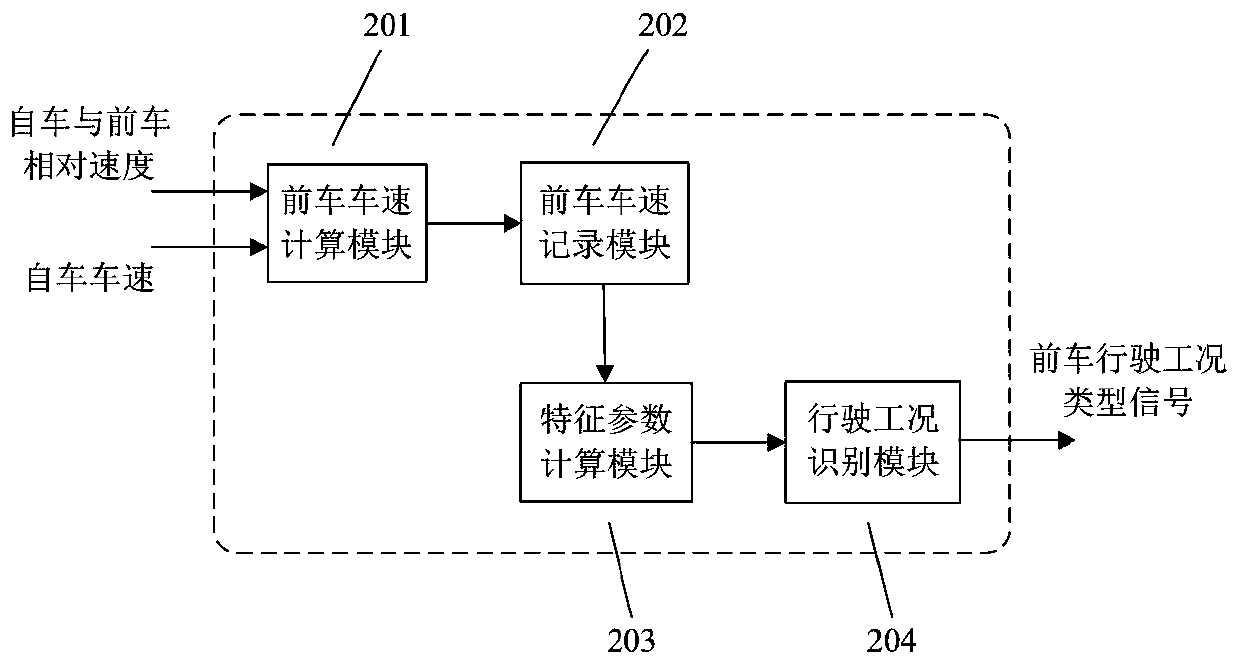

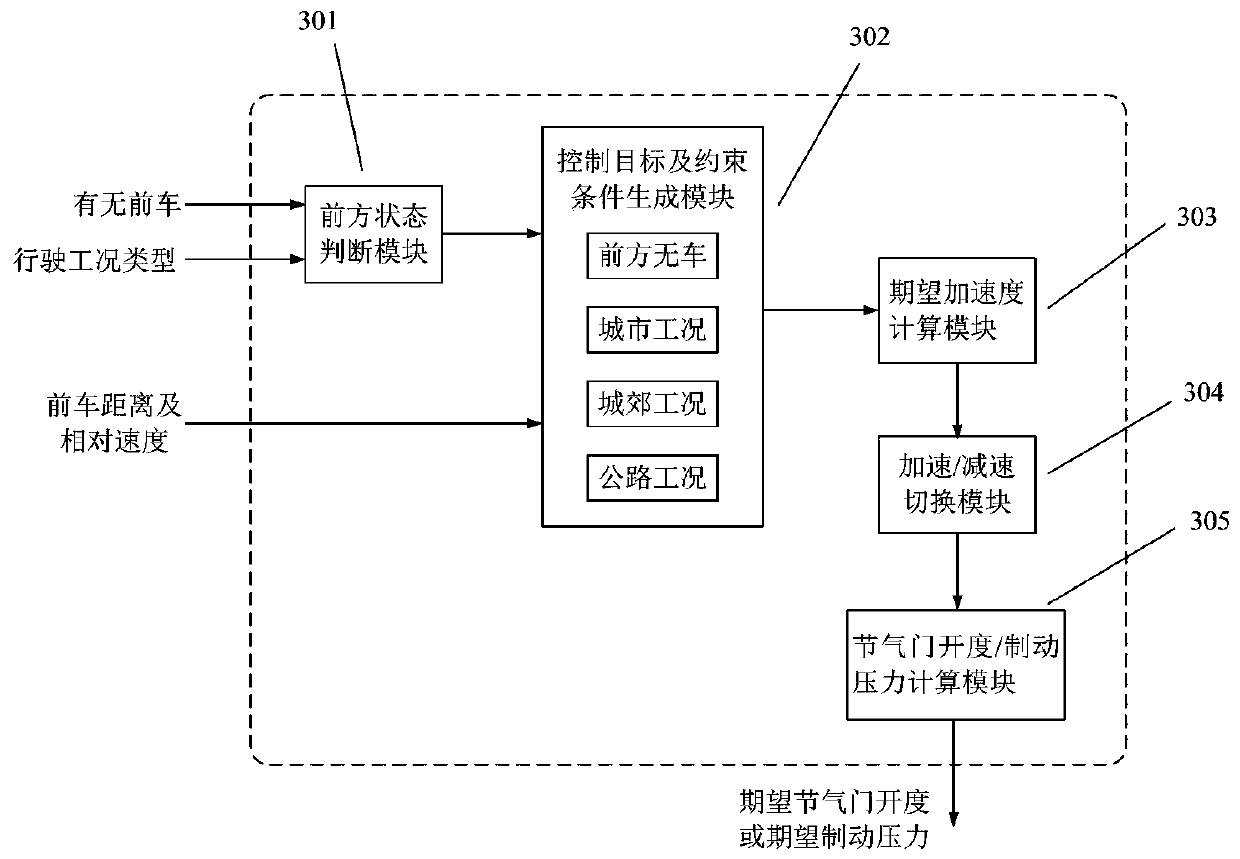

The invention discloses an economical adaptive cruise control system suitable for various driving conditions. The system comprises a millimeter wave radar, a vehicle speed sensor, a driving working condition identifier, an ACC controller and an acceleration / deceleration executive device; a running architecture of the driving working condition identifier comprises a front vehicle speed calculationmodule, a front vehicle speed recording module, a characteristic parameter calculation module and a driving working condition identification module; a running architecture of the ACC controller comprises a front state judgment module, a control target and constraint condition generation module, a desired acceleration calculation module, an acceleration / deceleration switching module and a throttleopening / brake pressure calculation module. The system can identify the driving state in front, the control target and the constraint condition of the adaptive cruise system can be reasonably selectedaccording to the recognition judgment result, the dynamic change of the importance degree of each performance under different driving conditions can be adapted, and the energy consumption economy canbe improved in a targeted mode under various working conditions.

Owner:JIANGSU UNIV

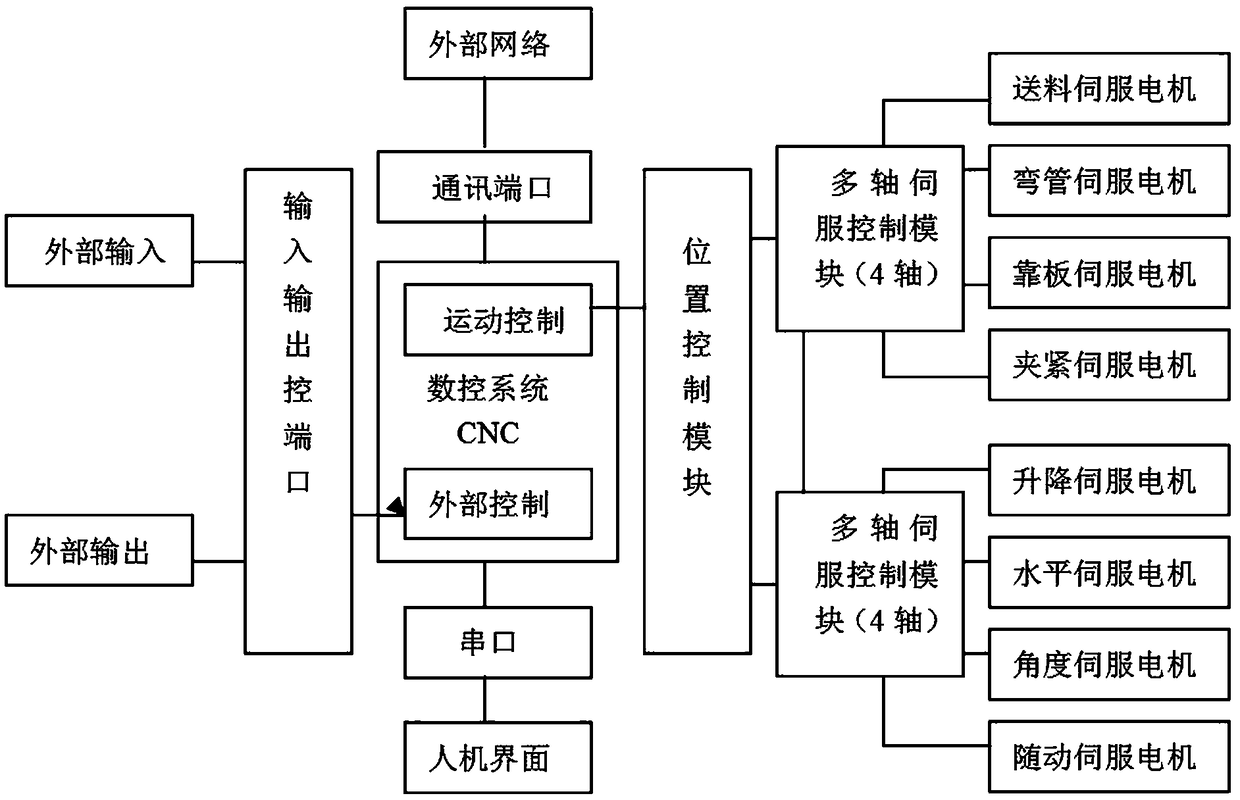

Numerical control pipe-bending machine control system

InactiveCN109127812AReduce springback deformationEnsure consistencyMetal-working feeding devicesPositioning devicesNumerical controlMachine control

The invention discloses a numerical control pipe-bending machine control system, and relates to the technical field of pipe bending machining. The numerical control pipe-bending machine control systemcomprises a central controller, external inputting equipment, external outputting equipment and a pipe-bending machine executing part. The pipe-bending machine executing part comprises a feeding servo mechanism, an angle rotating servo mechanism, a pipe-bending servo mechanism, a clamping servo mechanism, a lifting servo mechanism, a horizontal moving servo mechanism, a plate backing servo mechanism and a follow-up servo mechanism. According to the numerical control pipe-bending machine control system, moving at different angles and positions is completed through eight-axis servo control, bending machining at any angle and radius can be achieved, and the machining precision is guaranteed; and meanwhile, quick replacing of a pipe-bending mold and a feeding clamp can be structurally achieved, and thus, a pipe-bending machine has the function of welding prior to bending.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

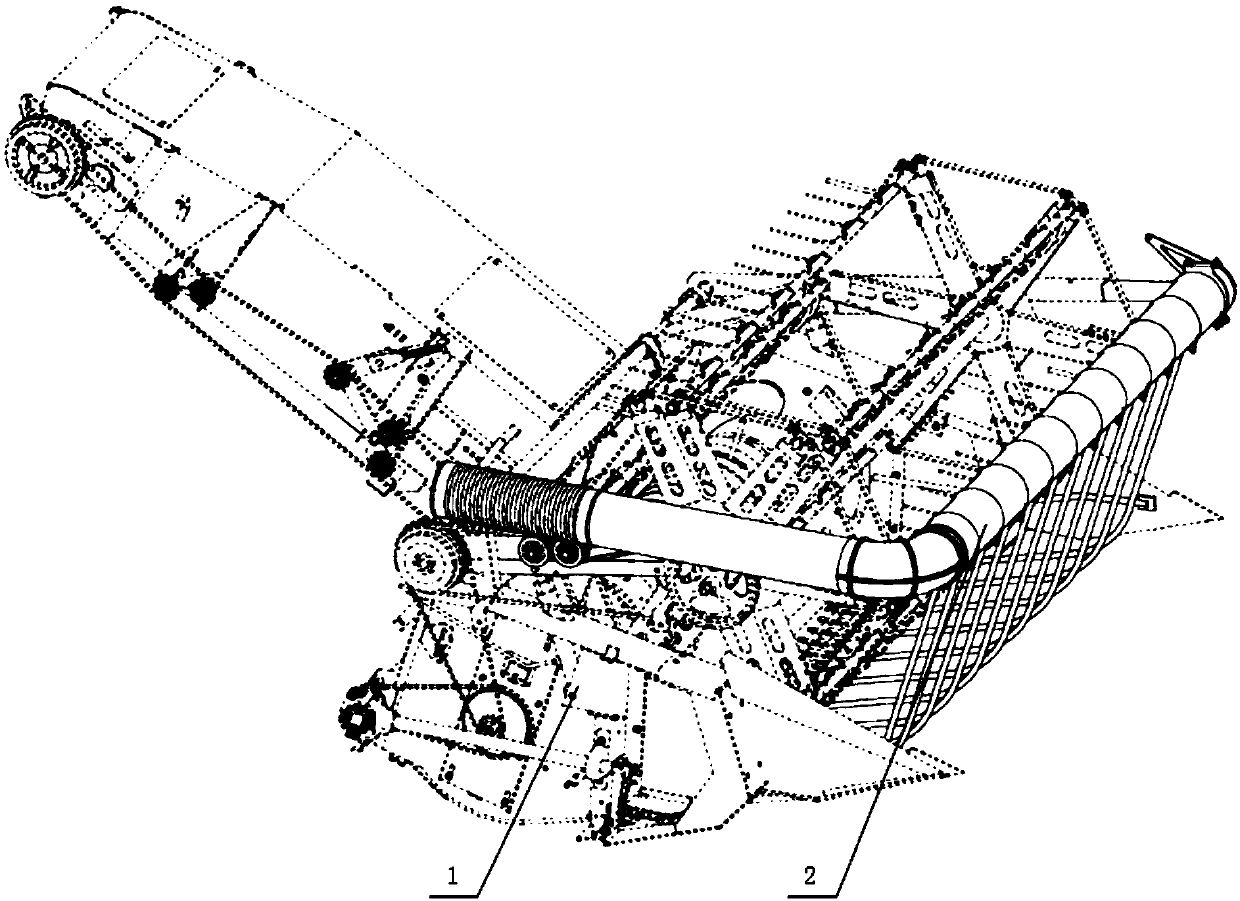

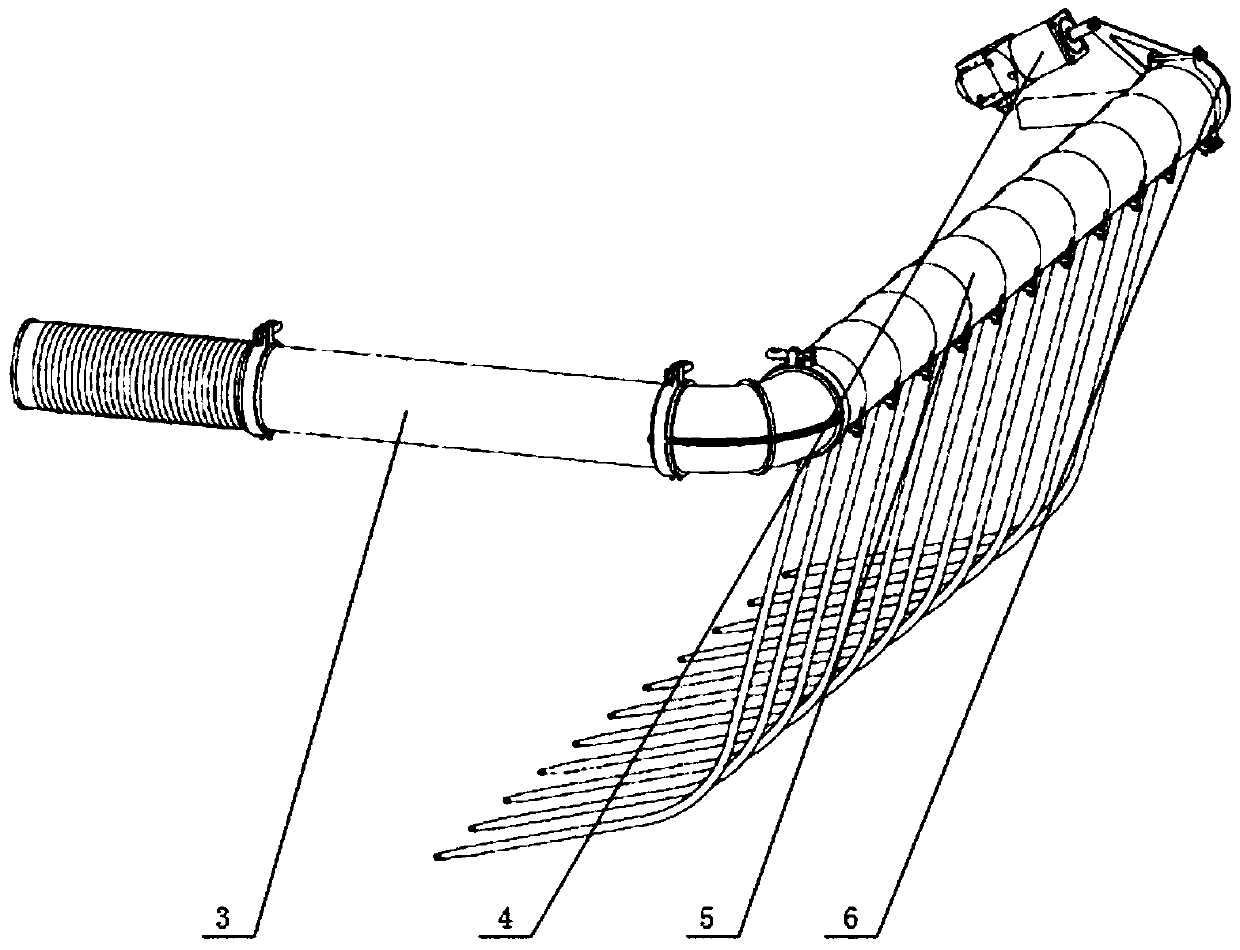

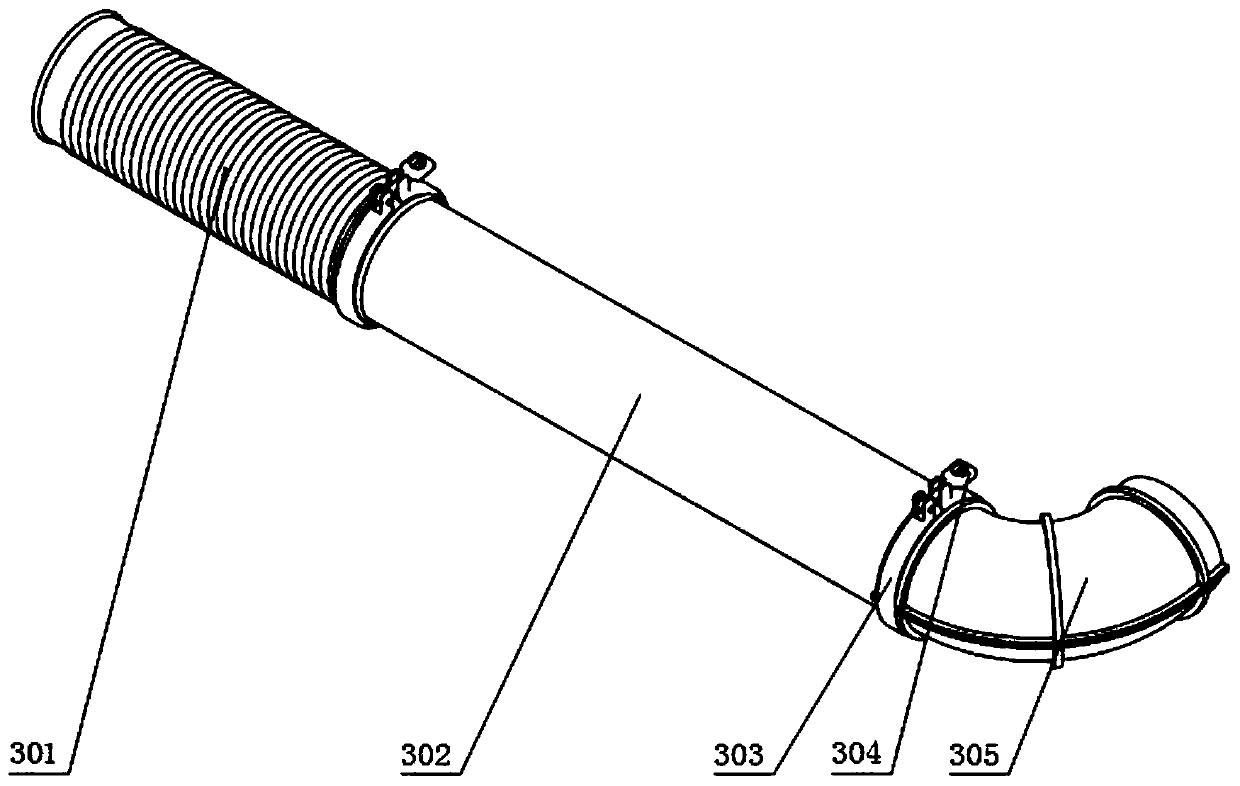

Pneumatic blowing device for header of combine harvester

The invention discloses a pneumatic blowing device for a header of a combine harvester, which comprises a header body, a servo electric cylinder and an air collecting pipe. The header body is interconnected with a pneumatic blowing assembly, and the air collecting pipe is interconnected with a tail end framework. The air collecting pipe is interconnected with a lower saddle and a U-shaped clamp, and the lower saddle is arranged below the U-shaped clamp, and the bottom end of the lower saddle is interconnected with the top end of an air nozzle. A wind collecting bushing is interconnected with areinforcing bent pipe, and the reinforcing bent pipe is interconnected with a ventilation straight pipe, and the reinforcing bent pipe and the ventilation straight pipe are both interconnected with aclamp. The ventilation straight pipe and a telescopic hose are connected with each other, and the telescopic hose and the clamp are connected with each other. According to the pneumatic blowing device for the header of the combine harvester, the novel structural design is adopted, so that the device can recover the loss before cutting, the power consumption is low and the efficiency is high. A recovery structure can be adjusted by an adjustment structure and the wind force is enough to recover pellets more efficiently and improve the recovery effect.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Code spraying device and code spraying method

InactiveCN106004085ANot easy to polluteReduce consumable costsDuplicating/marking methodsTypewritersSpray nozzleInjector

The invention provides a code spraying device and a code spraying method. The code spraying device comprises a feeding mechanism, a material carrier, a code spraying mechanism and a blanking mechanism. The material carrier is located at a downstream position of the feeding mechanism along a movement direction of materials; spray nozzles of the code spraying mechanism face to the materials on the material carrier; and the blanking mechanism is located at a downstream position of the material carrier along a flowing direction of the materials. The code spraying device and the code spraying method provided by the invention solve the problems of high consumable cost and low processing efficiency existed when code spraying is carried out on a medical injector in the prior art.

Owner:MAIDER MEDICAL IND EQUIP

Steel bar prestress tensioning machine

PendingCN108908693AGuaranteed normal transmissionGuaranteed follow-upShaping reinforcementsSteel barMechanical engineering

The invention relates to a steel bar prestress tensioning machine, wherein a first driving mechanism can drive a tensioning assembly to move to enable a steel bar to have axial deformation. The tensioning assembly is provided with a tensioning big nut, and the tensioning big nut sleeves a tensioning screw and can slide to be clamped on a fixed end plate to prevent the steel bar from recovering from the deformation. The tensioning assembly further includes a bracket that can move synchronously with the tensioning big nut away from the fixed end plate during the tensioning process. The bracket can slide towards the fixed end plate with the tensioning big nut synchronously in the tensioning big nut screwing process. The bracket is further provided with a nut sleeve detachably connected with the tensioning big nut, a second driving mechanism for driving the nut sleeve to drive the tensioning big nut to rotate and a transmission assembly. Regardless of whether the tensioning big nut moves towards or away from the fixed end plate, the bracket can move together with the tensioning big nut, and the second driving mechanism arranged on the bracket can rotate the tensioning big nut continuously without sudden stop. The structure is simple and ingenious.

Owner:周兆弟

Conveying roller way control device for producing corrugated paper through rolling temperature control

PendingCN112677572AImprove economyCost-effectiveMechanical working/deformationTemperature controlElectric machine

The invention discloses a conveying roller way control device for producing corrugated paper through rolling temperature control, and relates to a corrugated paper production control device. It is characterized in that a corrugated paper temperature control and speed control production line connector is fixedly mounted on the left side of an bottom frame, a lower roller assembly body is fixed on the upper part of the bottom frame, an upper roller assembly body is positioned on the upper part of the lower roller assembly body and is adjusted through a roller gap adjusting bolt structure, a sealing cover is fixed to the upper part of the upper roller assembly, an observation window is formed in the side part of the sealing cover, a variable-frequency gear motor is fixed to one side of the bottom frame, hot air source pipelines are arranged on the left side and the right side of the upper part of the upper roller assembly correspondingly, resistance heaters are fixed to the middle of the upper part of the upper roller assembly and the middle of the lower part of the lower roller assembly correspondingly, the roll gap adjusting bolt is used for adjusting a fixing gap between the lower roller assembly and the upper roller assembly, and the corrugated paper temperature control and the speed control production line lower roller assembly comprises a roller way I, a bearing end cover, a bearing block and a bearing. The device has the characteristics of efficient, accurate and low-consumption temperature control and speed control on conveying of corrugated paper production, and the product quality and the production efficiency are improved.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

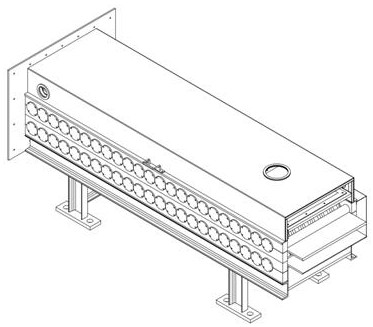

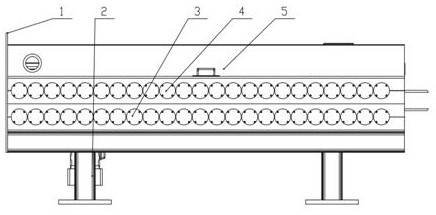

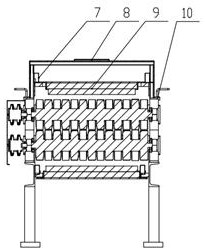

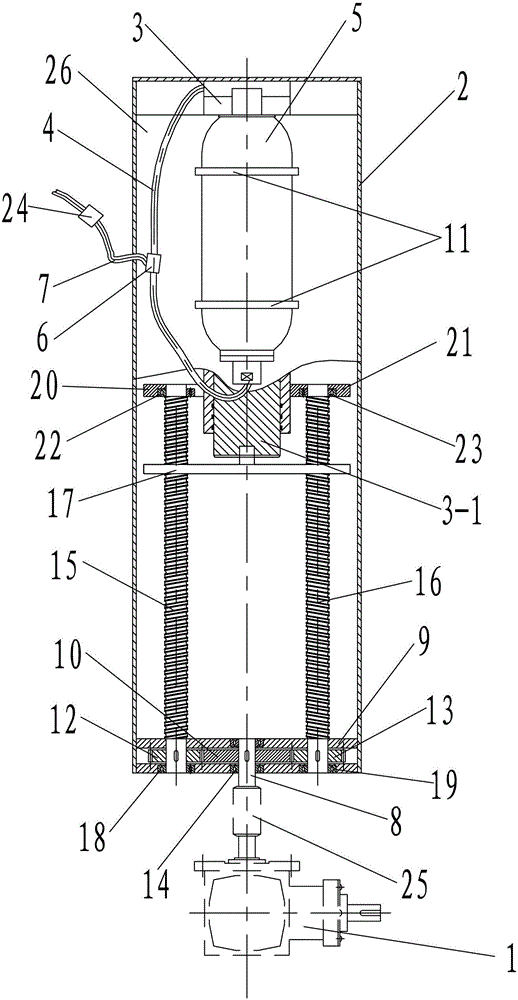

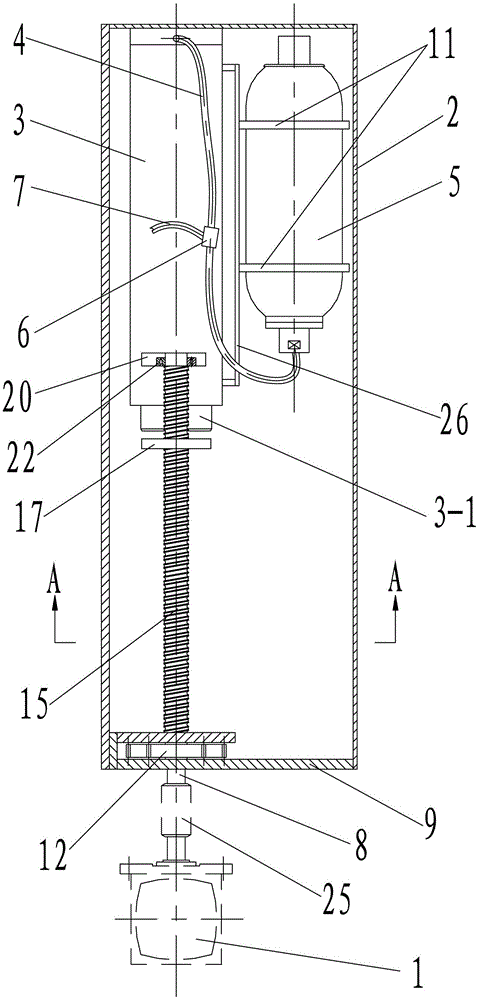

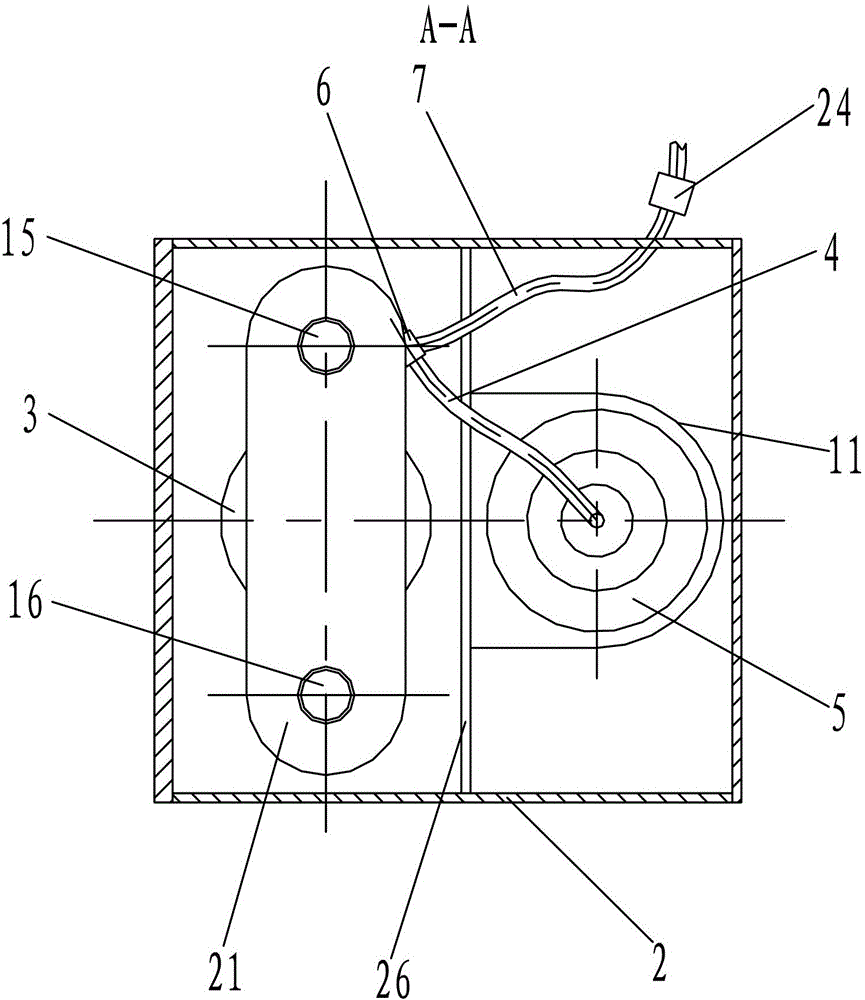

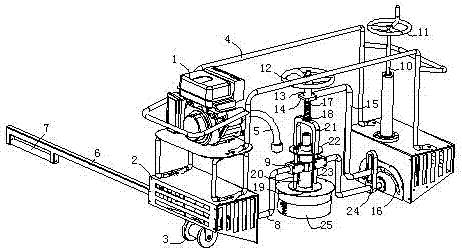

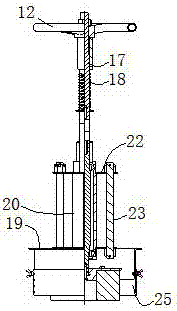

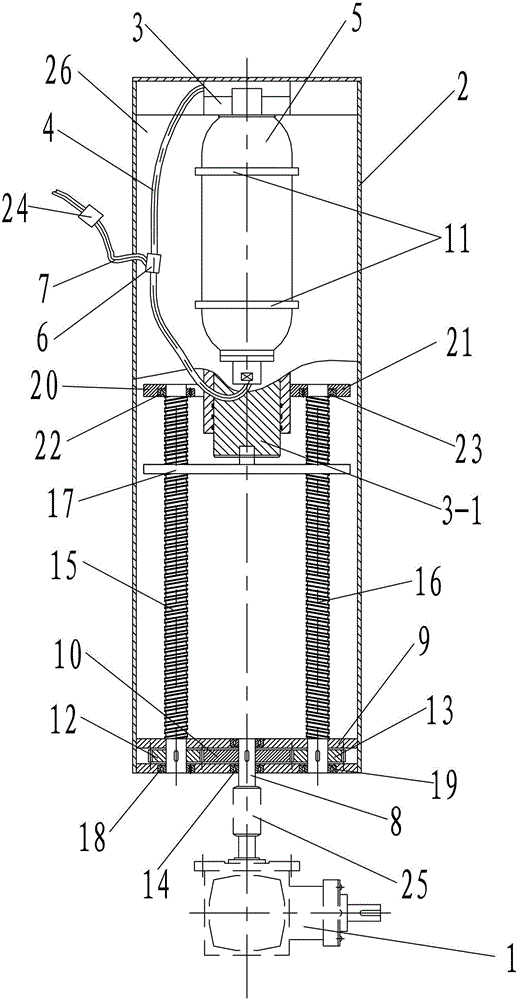

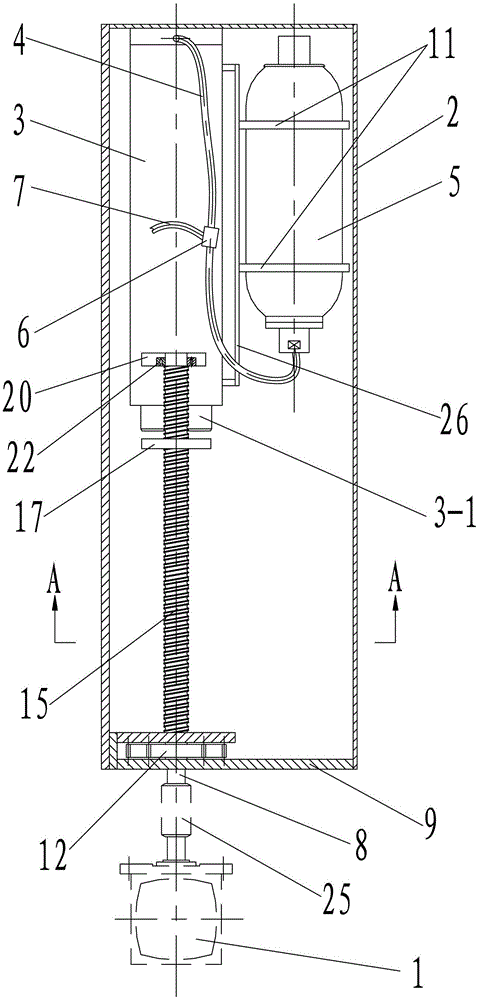

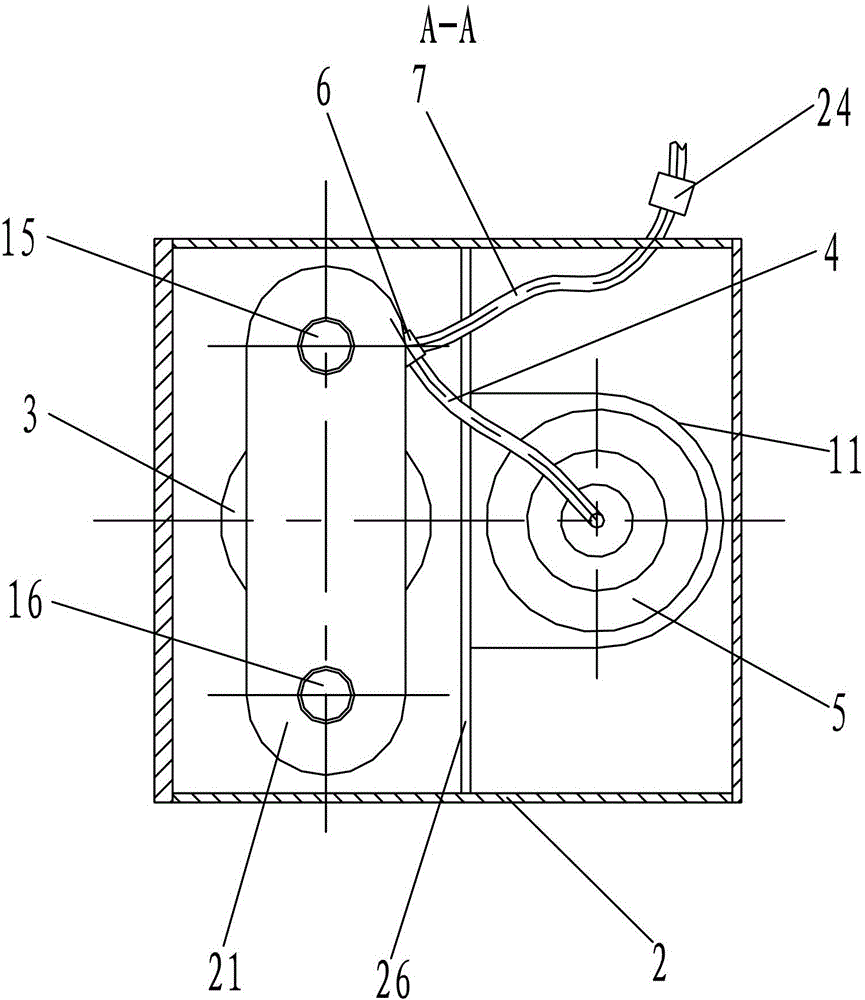

Servo device of trenching machine pipe coiling system

ActiveCN102979129ACompact structureNovel and reasonable designSoil-shifting machines/dredgersGear driveDrive shaft

The invention discloses a servo device of a trenching machine pipe coiling system. The device comprises a speed reducer, a constant tension control mechanism and a driving mechanism, wherein the constant tension control mechanism is used for providing constant tension to a hydraulic rubber pipe in a trenching machine; the driving mechanism is used for transmitting the power output by the speed reducer to the constant tension control mechanism; the constant tension control mechanism comprises a plunger type hydraulic oil tank and an energy accumulator connected with the plunger type hydraulic oil tank through a first oil pipe; a second oil pipe is connected with the first oil pipe through a tee joint; the driving mechanism comprises a driving shaft, a gear driving mechanism and a screw rod driving mechanism; the driving shaft is connected with the speed reducer; the gear driving mechanism is connected with the driving shaft; and the screw rod driving mechanism is connected with the gear driving mechanism, used for converting the rotary movement of the gear driving mechanism into the linear movement of a plunger rod in the plunger type hydraulic oil tank and is connected with the plunger rod in the plunger type hydraulic oil tank. The servo device is compact in structure, reasonable in design, convenient to mount and use, complete in function, good in servo performance, good in constant tension control effect, stable and reliable in performance and high in popularization and application value.

Owner:中铁二十局集团西安工程机械有限公司

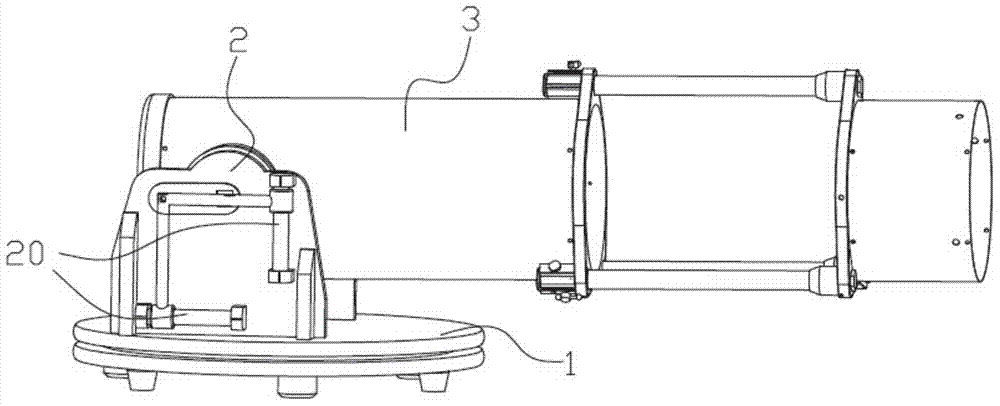

Balance mechanism for lens cone

The invention discloses a balance mechanism for lens cone, and the balance mechanism for lens cone comprises a fixing base used for fixing and mounting the lens cone of a telescope, two fixing sheets are vertically formed on the upper surface of the fixing base, two fixing sheets are symmetrically formed with interval and the lens cone is formed between two fixing sheets; a balance assembly is formed at the outer side of the fixing sheet, and the balance assembly comprises a first elastic piece, a second elastic piece, a first sliding rail and a second sliding rail, one end of the first elastic piece is fixedly connected to one end of the second elastic piece, the other end of the first elastic piece is connected to the first sliding rail in a sliding mode while the other end of the second elastic piece is connected to the second sliding rail in a sliding mode, the first elastic piece and the second elastic piece can slide along the first sliding rail and the second sliding rail while the lens cone rotates. The balance mechanism for lens cone is reasonable in strdryucture design, the balance and stable state for center of gravity for the lens cone can be guaranteed under any rotating angle of the lens cone, the measurement precision for the telescope and the following shoot to the object can also be guaranteed with good practical value.

Owner:江苏斯图加特光学有限公司

Grinding wheel control device for sander for steel rail

InactiveCN107130483AConvenient continuous grindingFacilitate tightness adjustmentRailway track constructionSanderEngineering

The invention discloses a grinding wheel control device for a sander for a steel rail. The grinding wheel control device comprises a grinding wheel device and a rotation regulating mechanism. The grinding wheel control device is characterized in that the rotation regulating mechanism comprises a deflection regulating elbow; two ends of the deflection regulating elbow are horizontally arranged, and further, are each rotatablely mounted on two supporting shells; the middle part of the deflection regulating below is provided with a U-shaped bent part which is upwards concave; the middle part of the bent part is provided with a mounting block for mounting the grinding wheel device; one end of the deflection regulating elbow is a rotation regulating input end; the end part of the rotation regulating input end is provided with a worm wheel; the worm wheel cooperates with a worm vertically mounted on the supporting shell; the upper end of the worm upwards extends out of the supporting shell and is horizontally provided with a rotation control hand wheel. The grinding wheel control device can be used for the sander for the steel rail, so as to be better beneficial to the realization of the tightness regulation and the grinding direction regulation of a grinding wheel, and has advantages of being convenient to operate, flexible to regulate and convenient for realizing the continuous sanding of multiple side surfaces of the steel rail, and the like.

Owner:CHONGQING UNIV OF TECH

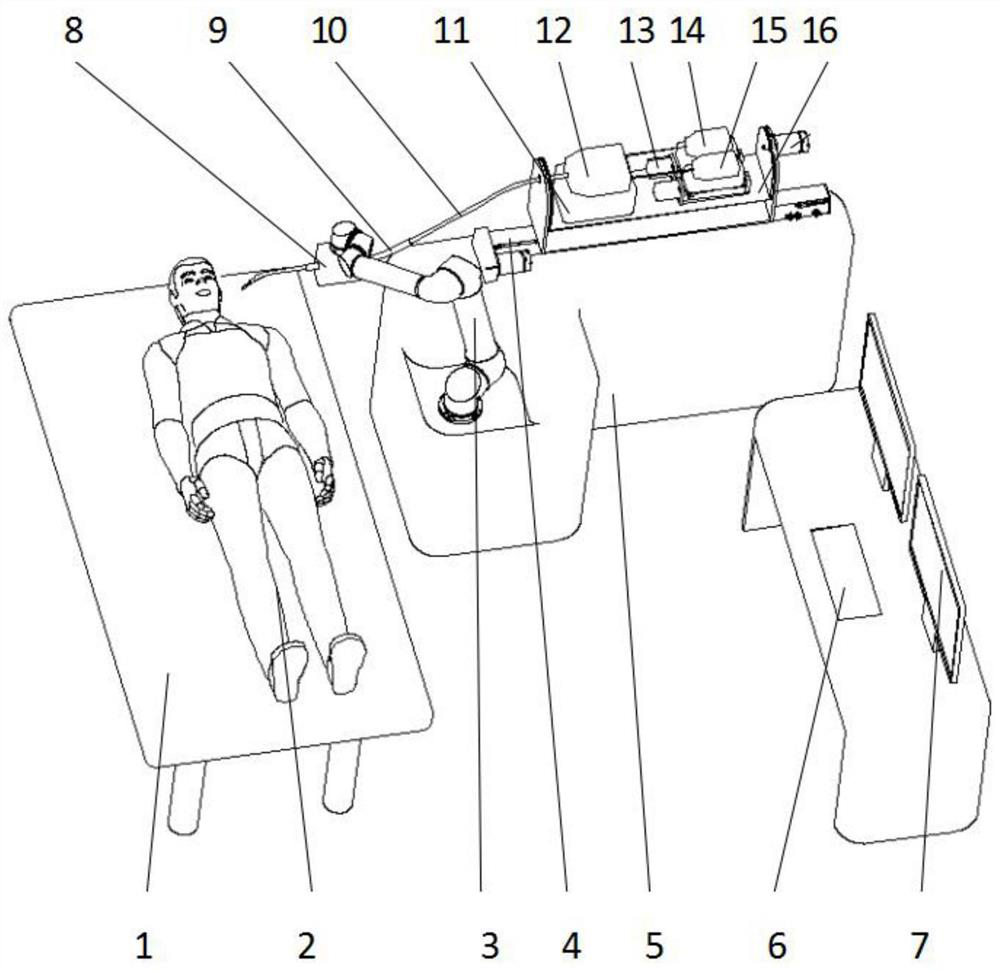

Endoscopic surgical instrument conveying device, control method and robot system

ActiveCN114010318AEasy to movePrecise positioningDiagnosticsSurgical manipulatorsRobotic systemsPhysical medicine and rehabilitation

The invention discloses an endoscopic surgical instrument conveying device, a control method and a robot system. The endoscopic surgical instrument conveying device comprises a robot base, a multi-degree-of-freedom mechanical arm, a first driving platform, a second driving platform and a control module. In an adjusting and aligning stage, the control module calculates the sliding distance of the first driving platform according to movement position conversion of a pipe conveying assembly of the multi-degree-of-freedom mechanical arm, and controls the first driving assembly to drive the first driving platform to move along with the multi-degree-of-freedom mechanical arm; and in a tube body insertion stage, the control module controls the first driving assembly to drive the first driving platform to slide, so that the endoscope body insertion tube is inserted towards the far end. By means of the control module, in the alignment process, when the multi-degree-of-freedom mechanical arm is moved, the first driving platform slides synchronously, the overall follow-up effect of the endoscope body insertion tube is kept, the situation that the endoscope body insertion tube is straightened, tightened and stressed due to distance changes is avoided, and the stable positioning process is achieved.

Owner:SUZHOU ZHONGKE HUAYING HEALTH TECH CO LTD

Grinding wheel control device for rail grinding machine

InactiveCN107130483BGuaranteed follow-upGuaranteed reliabilityRailway track constructionSanderEngineering

The invention discloses a grinding wheel control device for a sander for a steel rail. The grinding wheel control device comprises a grinding wheel device and a rotation regulating mechanism. The grinding wheel control device is characterized in that the rotation regulating mechanism comprises a deflection regulating elbow; two ends of the deflection regulating elbow are horizontally arranged, and further, are each rotatablely mounted on two supporting shells; the middle part of the deflection regulating below is provided with a U-shaped bent part which is upwards concave; the middle part of the bent part is provided with a mounting block for mounting the grinding wheel device; one end of the deflection regulating elbow is a rotation regulating input end; the end part of the rotation regulating input end is provided with a worm wheel; the worm wheel cooperates with a worm vertically mounted on the supporting shell; the upper end of the worm upwards extends out of the supporting shell and is horizontally provided with a rotation control hand wheel. The grinding wheel control device can be used for the sander for the steel rail, so as to be better beneficial to the realization of the tightness regulation and the grinding direction regulation of a grinding wheel, and has advantages of being convenient to operate, flexible to regulate and convenient for realizing the continuous sanding of multiple side surfaces of the steel rail, and the like.

Owner:CHONGQING UNIV OF TECH

Tractor suspension force measuring device

PendingCN108844666AGuaranteed follow-upSlow down drastic changesForce measurementCouplingUniversal joint

The invention relates to a tractor suspension force measuring device. The tractor suspension force measuring device comprises an axle pin sensor, wherein the axle pin sensor is connected between a rear end device and a front end traction device through a universal joint coupling, the axle pin type sensor includes an axle pin, the axle pin is provided with a through hole in the axial direction, a first double shear strain gauge and a second double shear strain gauge are disposed in the through hole, the first double shear strain gauge and the second double shear strain gauge are disposed on a tractor traction force measuring point, the first double shear strain gauge includes a first strain gauge and a second strain gauge, the second double shear strain gauge includes a third strain gauge and a fourth strain gauge, and the first strain gauge, the second strain gauge, the third strain gauge and the fourth strain gauge are connected in series. The traction force with the changing direction is transformed into the radial force with the fixed direction for the pin, drastic change of a measured value with change of a suspension angle is weakened, and detection accuracy is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

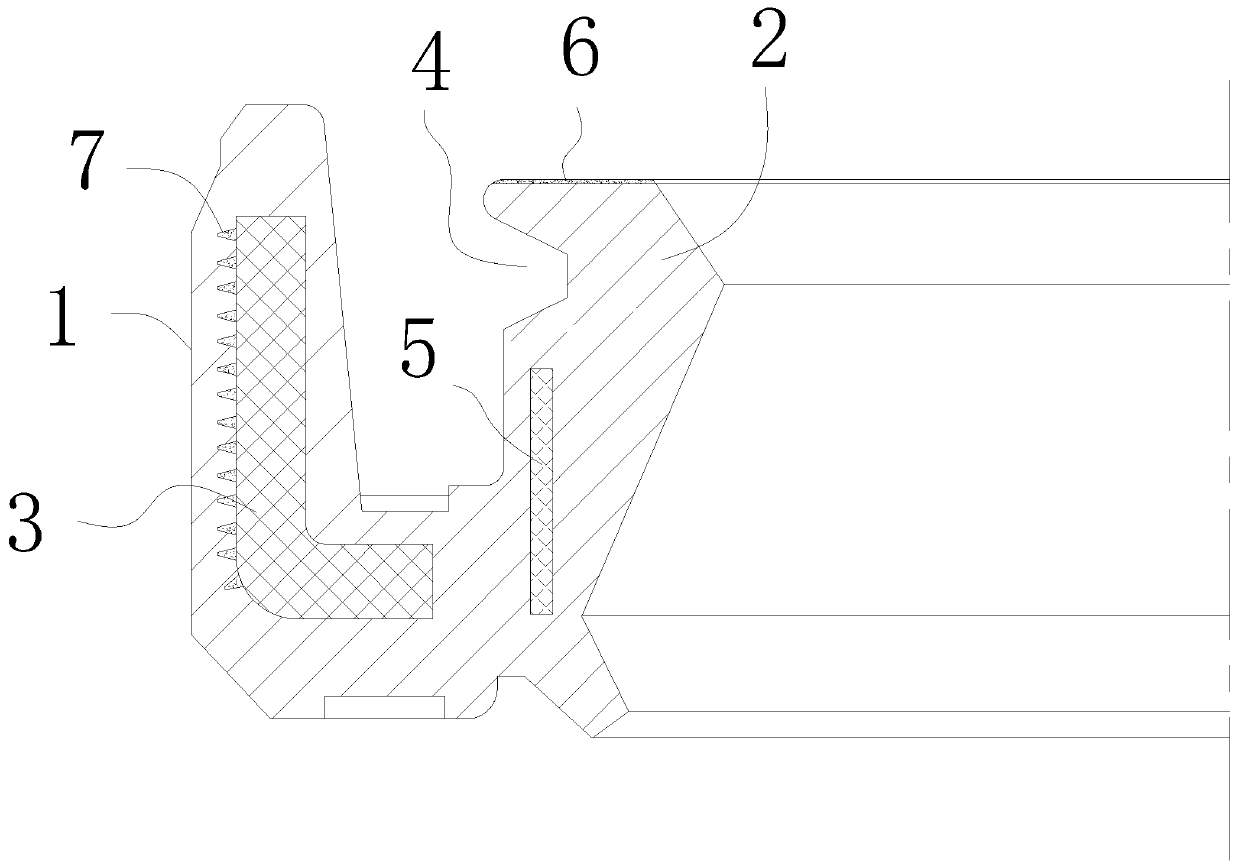

Rotating shaft lip seal ring

InactiveCN110043666AImprove sealingIncreased durabilityEngine sealsPolytetrafluoroethyleneEngineering

Owner:ANHUI RUNKANG RUBBER & PLASTIC TECH CO LTD

Team cooperation management method with secretary function

The invention discloses a team cooperation management method with a secretary function. The method comprises the following steps that: 1, the information of each team member is collected, and a team member information database is built through a network platform; 2, the team members input the types of work at which the team members are skilled through a team member port of the network platform to obtain a team member skilled work type database; and step 3, the team leader issues a task to the network platform through a secretary module, and the network platform classifies the task and compares the task type with the team member skilled work type database. According to the scheme, in the using process, a task issued by the leader can be classified and the type of the task can be determined, a team member skilled at the type is chosen according to the task type to determine a good plan firstly, the plan is shared to all the team members, after all the team members carry out collaborative modification, the modified plan is sent to the team leader, and after the team leader confirms, the team members skilled at the type of task are assigned to execute the task.

Owner:珠海科技学院

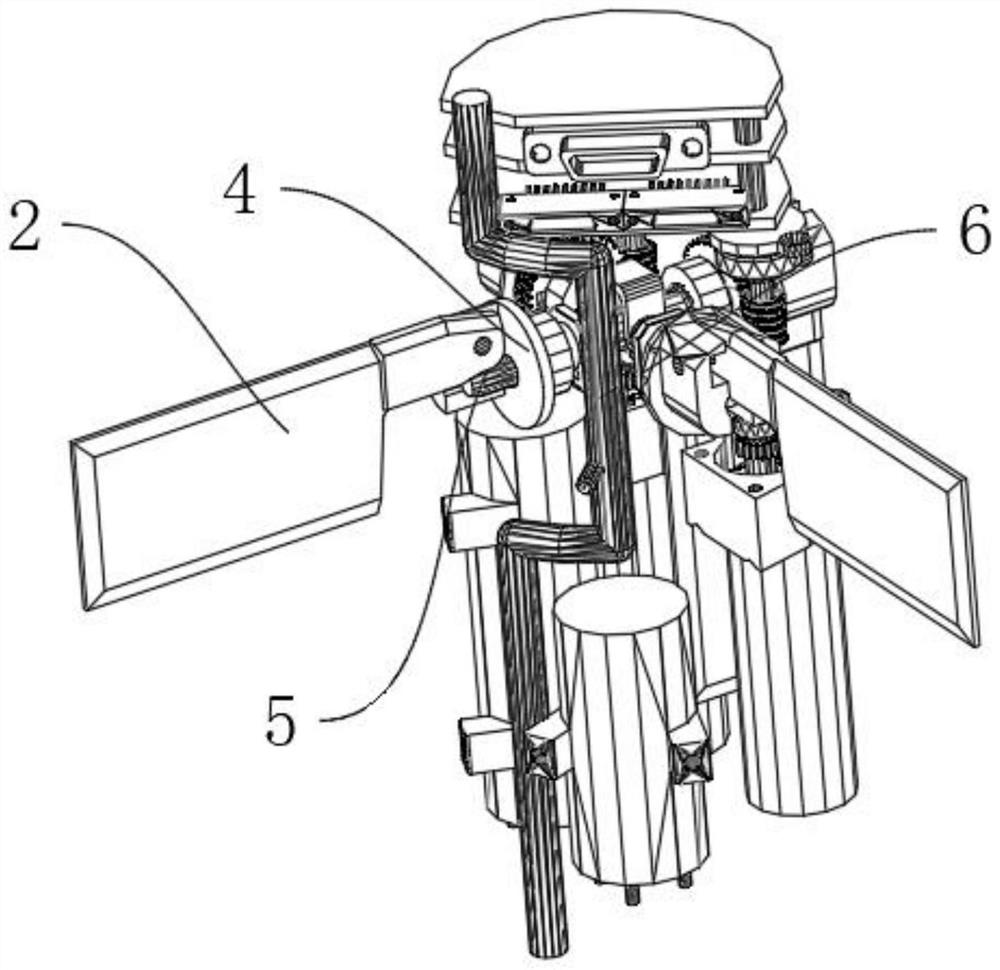

Pop-up mechanism applied to steering engine and steering wing of aircraft

PendingCN114368471AGuaranteed follow-upImprove practicalityAircraft controlWith power amplificationFlight vehicleMechanical engineering

The invention discloses a pop-up mechanism applied to an aircraft steering engine and a rudder wing, the pop-up mechanism comprises the rudder wing, rudder wing pop-up fixing blocks, rudder wing pop-up pins and a steering engine shell, a steering engine part is arranged in the steering engine shell, and four rudder wing pop-up fixing blocks are arranged between the outer side of the steering engine part and the steering engine shell; the rudder wing is fixed to the rudder wing pop-up fixing block, a rudder wing hiding groove is formed between the rudder wing and the steering engine shell, a rudder wing pop-up spring is arranged in the rudder wing pop-up fixing block, and the rudder wing pop-up pin is arranged at the position, located on one side of the rudder wing, of the rudder wing pop-up spring. A containing groove is formed between the rudder wing pop-up pin and the rudder wing pop-up fixing block. The rudder wing ejection pin and the rudder wing ejection spring are matched to eject out the rudder wing, so that it is guaranteed that the rudder wing can be rapidly unfolded after the steering engine shell is ejected out, follow-up operation is guaranteed, and the practicability of the device is improved.

Owner:洛阳安怀达智能科技有限公司

Servo device of trenching machine pipe coiling system

ActiveCN102979129BCompact structureNovel and reasonable designSoil-shifting machines/dredgersGear driveGear wheel

Owner:中铁二十局集团西安工程机械有限公司

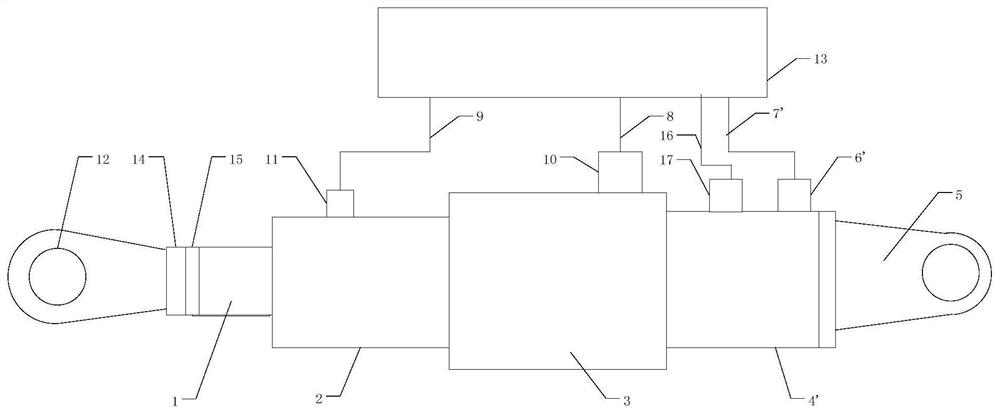

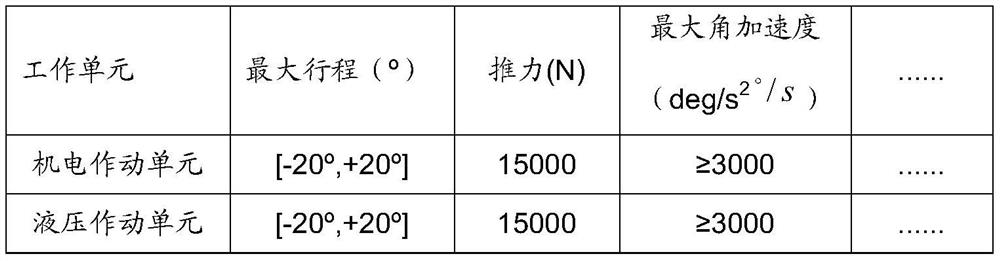

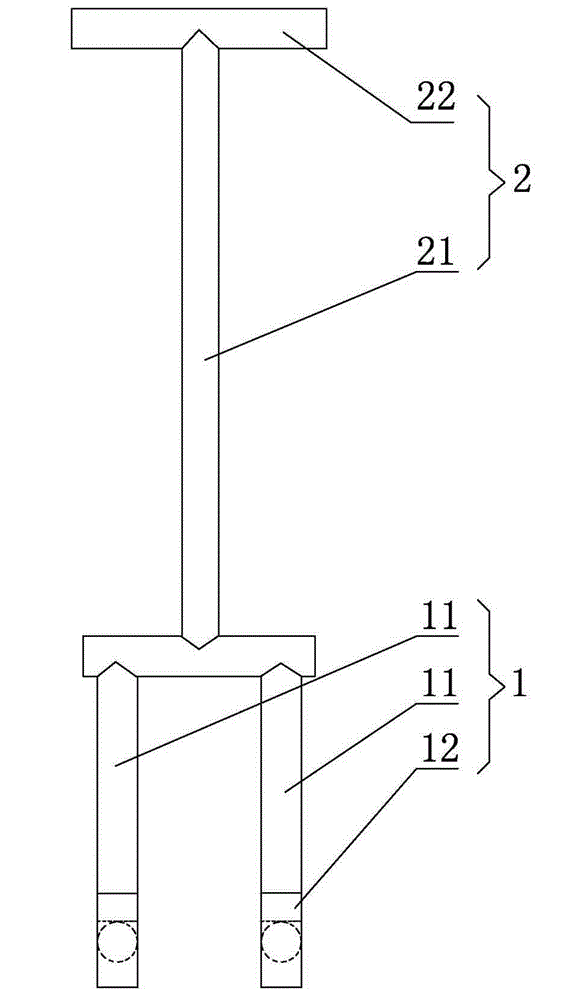

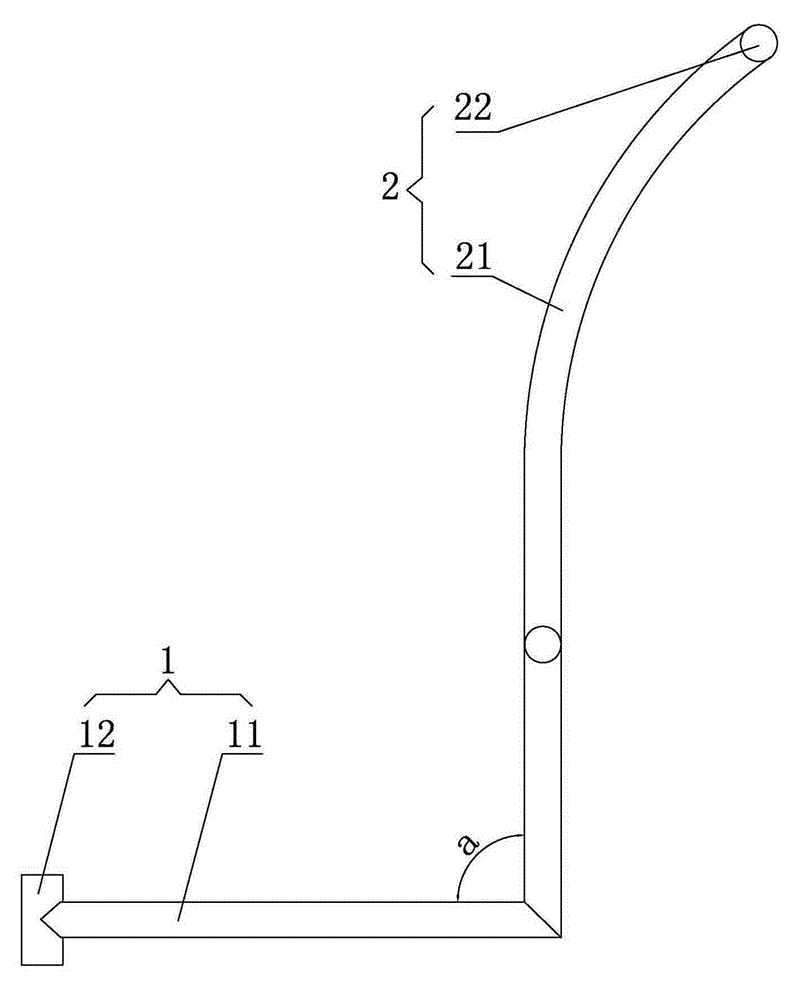

Electromechanical actuator capable of achieving full-scale, non-full-scale or follow-up function after lead screw is stuck

PendingCN112253571AGuaranteed follow-upSave costsSteering ruddersWith power amplificationElectromechanical actuatorBearing (mechanical)

The invention discloses an electromechanical actuator capable of achieving a full-scale, non-full-scale or follow-up function after a lead screw is stuck. A hydraulic actuating unit or a follow-up unit is ingeniously connected between a motor end and a rear support lug end of the electromechanical actuator, and when a lead screw pair of the electromechanical actuator is stuck at any position, thehydraulic actuating unit works, and the full-scale function or the non-full-scale function of the electromechanical actuator is achieved; or the follow-up unit works, and the follow-up function of theelectromechanical actuator is achieved. During bearing, the hydraulic actuating unit or the follow-up unit does not work, once the lead screw pair of the electromechanical actuator is stuck at any position, the hydraulic actuating unit or the follow-up unit is activated and starts to work, and the full-scale function or the non-full-scale function or the follow-up function is achieved according to actual working conditions.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Special extraction tool for hydraulic injector and extraction method for underwater hydraulic injector

InactiveCN102747971BEasy to operateIncrease success rateBorehole/well accessoriesMarine engineeringManipulator

The invention discloses a special take-out tool and a take-out method for a hydraulic injector. The special take-out tool for the hydraulic injector comprises a clamping take-out part and a handle part; the clamping take-out part consists of two parallel clamping bars; the middle parts of both the clamping bars are bent into a preset angle; the handle part consists of a vertical rod and a cross bar; the cross bar is fixed at one end of the vertical rod; and the other end of the vertical rod is fixedly connected to one end of the clamping take-out part. The invention ingeniously applies the lever principle, so that the force for pulling out the injector is greatly increased. When the special take-out tool for the hydraulic injector is in use, the handle part of the special take-out tool is grasped by an underwater robot; then a take-out part of the hydraulic injector is clamped by the tool; and by using the right angle point of the tool as the fulcrum, the handle part is repeatedly pressed by a manipulator of the underwater robot, so that the hydraulic injector can be rapidly taken out of an underwater facility injection hole and the success rate is ultrahigh.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Accelerometer core butting structure and butting method

PendingCN110887973ACompact structureEasy to operateSpeed/acceleration/shock instrument detailsAccelerometerStructural engineering

The invention belongs to an accelerometer mounting structure and mounting method, aims to solve the technical problems of damage to the core or inaccurate butting caused by excessively butting force or uneven force and the fact that the butting force cannot be quantified when the core is butted, and provides an accelerometer core butting structure and butting method. Flexible axial butting betweena first axial ejector rod and a second axial ejector rod is achieved through the butting structure by means of a first spring, and a first radial adjusting rod and a second radial adjusting rod are matched with a first radial push plate and a second radial push plate respectively to conduct radial butting on the accelerometer core. The butting method comprises the following steps: firstly, the first radial adjusting rod and the second radial adjusting rod are used, a first radial push plate and a second radial push plate are close to each other, the core is placed between the two radial pushplates, then the core is axially positioned and radially adjusted again, the mass center of the core to be installed, the first axial ejector rod and the second axial ejector rod are located on the same straight line and then glue pouring packaging is carried out to complete butting.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com