Steel bar prestress tensioning machine

A prestressing and tensioning machine technology, applied in the field of construction engineering, can solve the problems of large human operation errors, manual on-duty, time-consuming and labor-intensive problems, and achieve the effects of high synchronization, reliable structure, simple and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

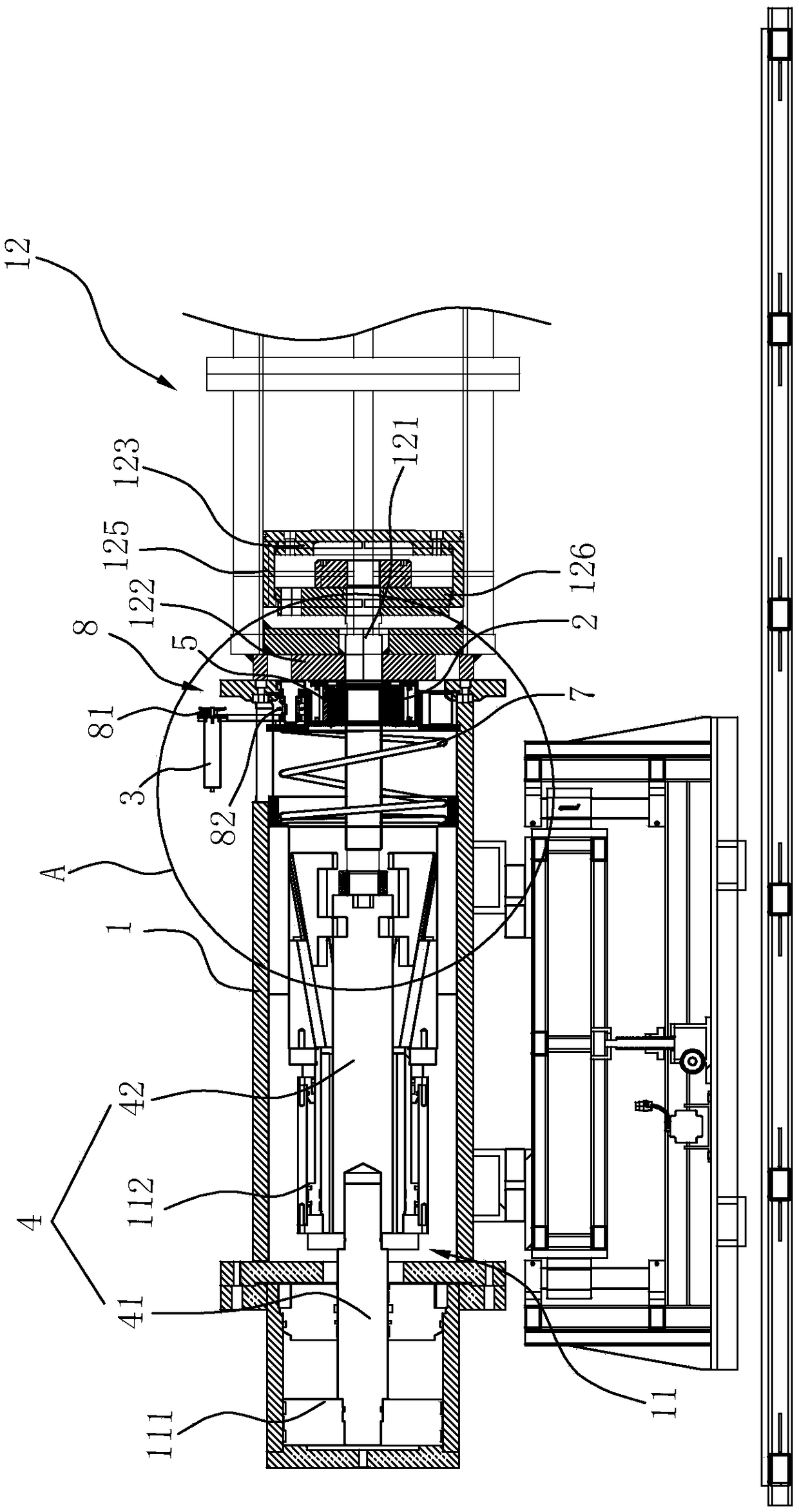

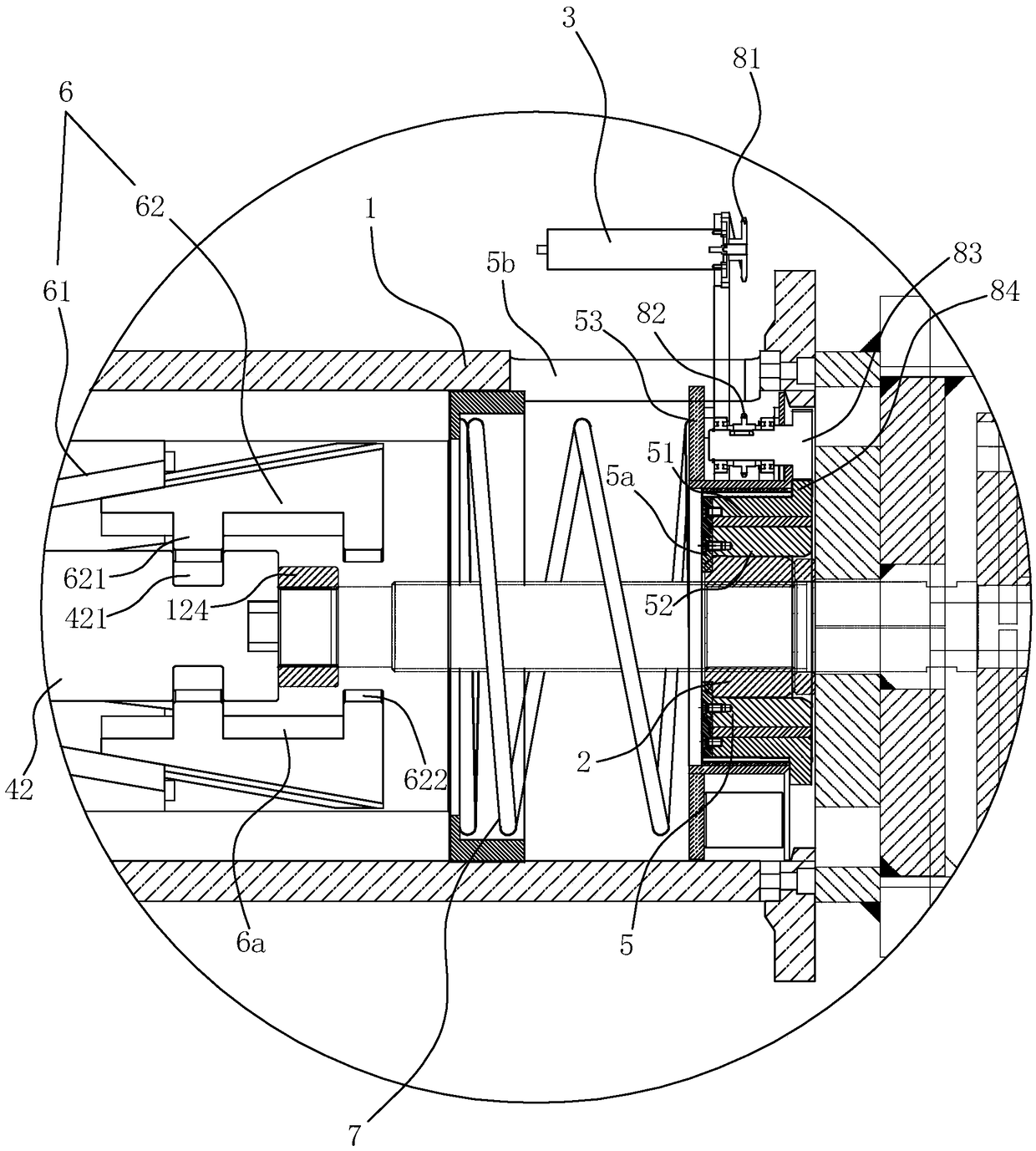

[0020] Such as figure 1 and figure 2 As shown, it is a preferred embodiment of the present invention. In this embodiment, the steel bar prestressed tensioning machine includes a fuselage 1, and the fuselage 1 is provided with a first driving mechanism 11, and the first driving mechanism 11 can drive the tensioning machine. The tensioning assembly 12 moves to cause axial deformation of the steel bar. The tensioning assembly 12 has a large tensioning nut 2 sleeved on the tensioning screw rod 121 that can slide and is locked on the fixed end plate 122 to prevent the deformation of the steel bar from recovering. It also includes a bracket 53 that can move synchronously with the tension nut 2 to the direction away from the fixed end plate 122 during the tensioning process, and the bracket 53 can move with the tension nut 2 during the process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com