Electromechanical actuator capable of achieving full-scale, non-full-scale or follow-up function after lead screw is stuck

A technology of electromechanical actuator and lead screw card, which is applied in the field of flight control execution, can solve the problems of launch vehicle failure, steering rudder stuck, uncontrollable impact, etc., and achieve the effect of saving length cost and complex development cycle cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

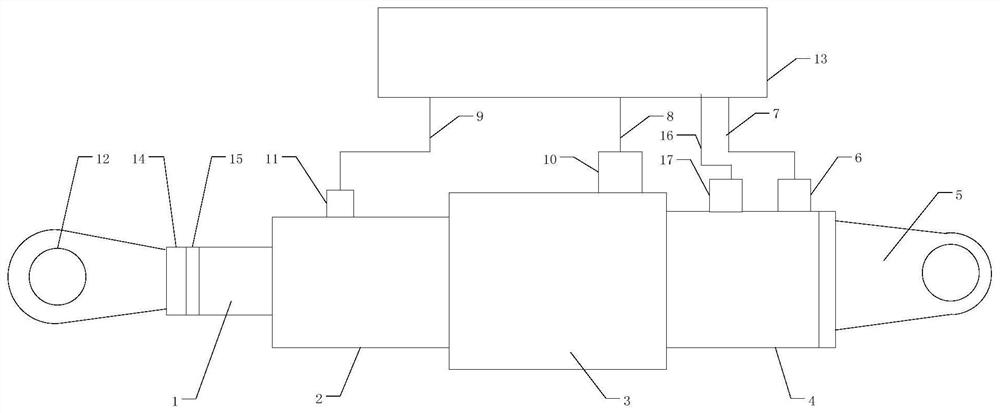

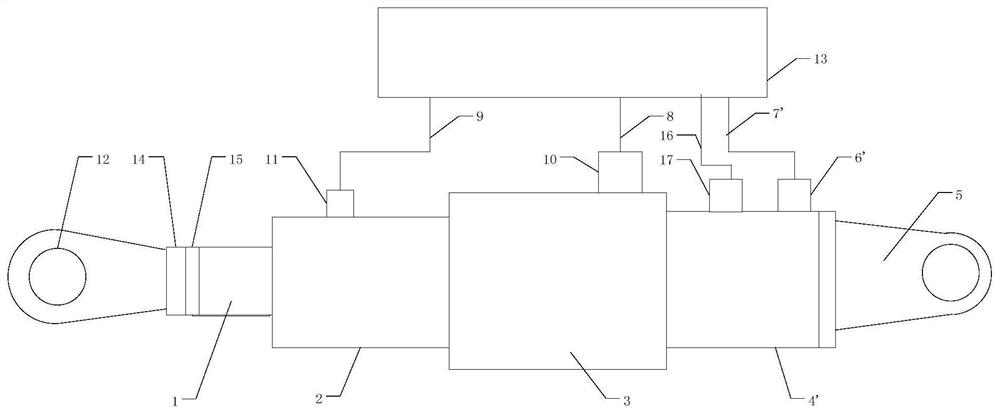

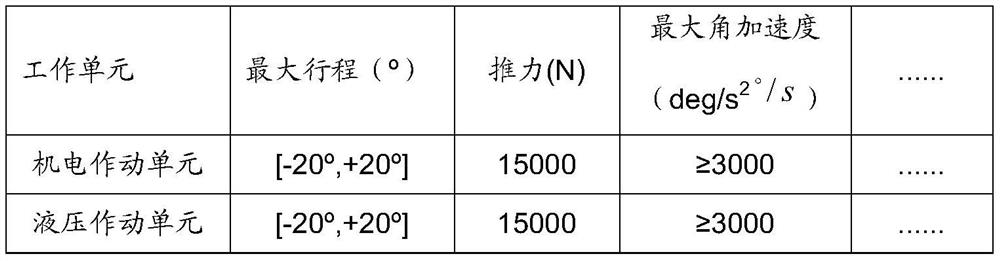

[0042] In the present invention, a hydraulic actuating unit is connected in series between the motor end of the electromechanical actuator (or the end of the motor and the reducer assembly or the end of the motor and the differential assembly) and the end of the rear lug, and the screw pair of the electromechanical actuator is locked at any position. When dead, the hydraulic actuating unit works to realize the full-scale or non-full-scale function of the actuator. If the lead screw pair of the electromechanical actuator is stuck at any position, the hydraulic actuating unit is activated and starts to work, and realizes the full-scale function or the non-full-scale function according to the actual working conditions.

[0043]In the present invention, the servo unit is connected in series between the motor end of the electromechanical actuator, the motor and reducer assembly end or the motor and differential gear assembly end, and the rear lug end, so that when the lead screw pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com