Accelerometer core butting structure and butting method

A technology of accelerometer and watch movement, applied in speed/acceleration/shock measurement, detailed information of speed/acceleration/electric shock meter, measuring device, etc. It can solve the problem of unquantifiable docking force, damaged docking of watch movement, and uneven force application and other problems, to achieve the effect of increasing the adjustable range, increasing the stepping accuracy, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

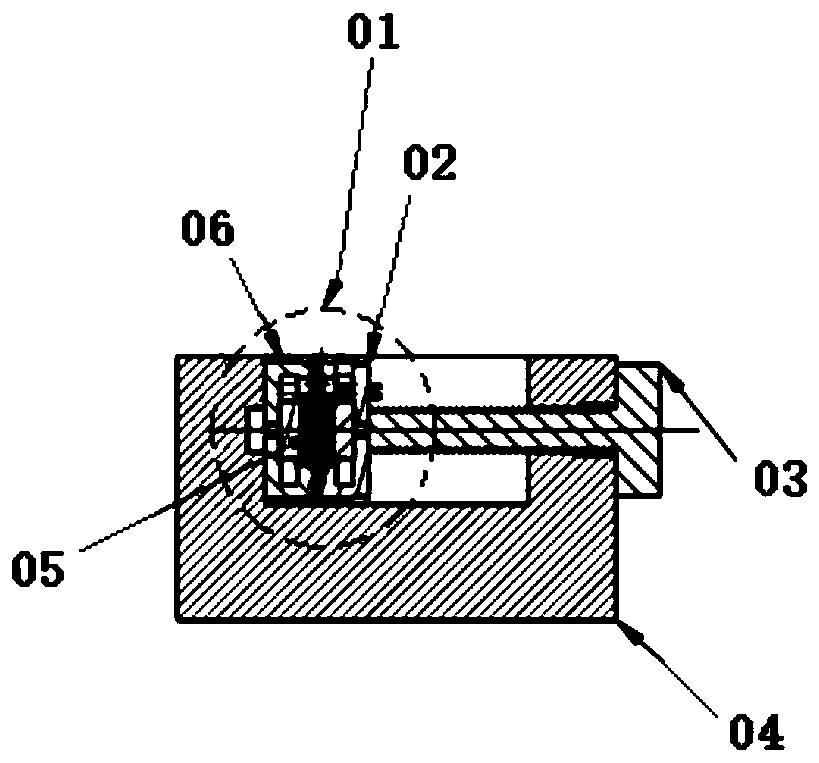

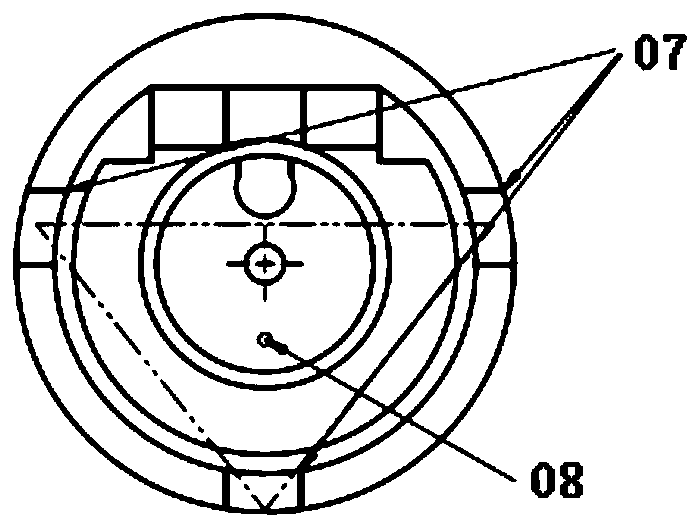

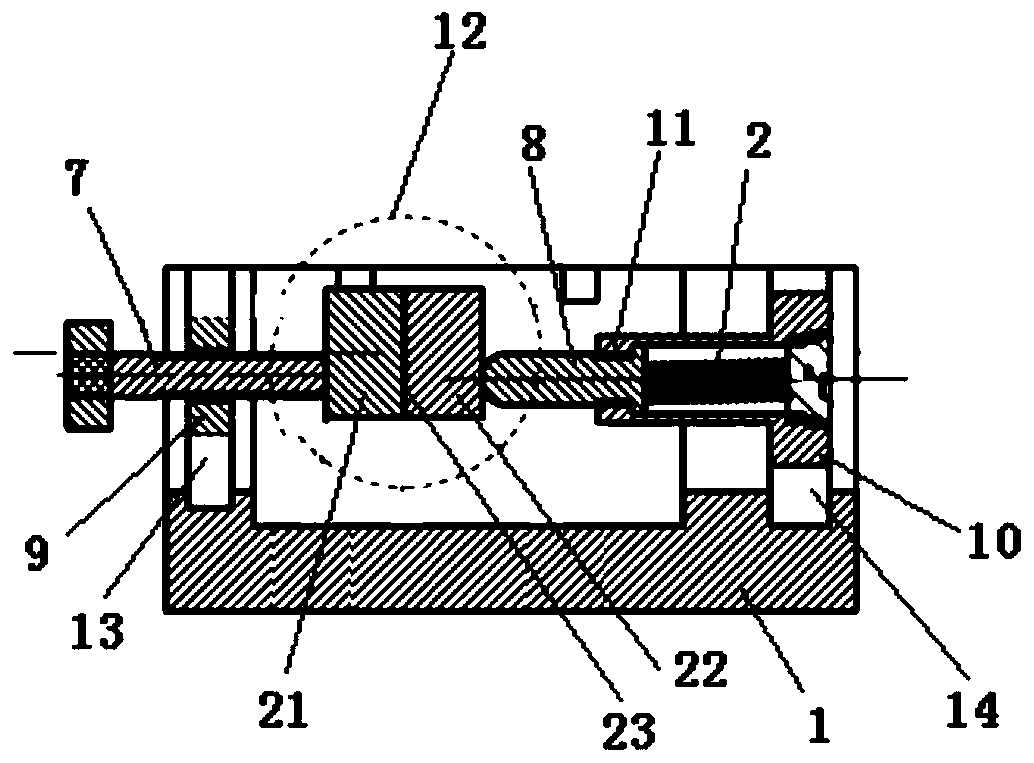

[0040] Such as image 3 and Figure 4 As shown, a docking structure of an accelerometer watch core includes a first axial push rod 7, a second axial push rod 8, a first radial push plate 3, a second radial push plate 4, a first radial adjustment The rod 5 and the second radial adjustment rod 6; the docking base 1 is provided with a first sliding cavity 13 and a second sliding cavity 14 along the vertical direction.

[0041]The first axial push rod 7 passes through the side wall of the docking base 1 and is arranged in the axial direction of the watch movement 12 to be installed. The first axial push rod 7 is covered with a first mounting seat 9, and the first mounting seat 9 is installed on the docking In the first sliding cavity 13 in the base 1, the first mounting seat 9 is screwed with the first axial push rod 7; the second axial push rod 8 is coaxially arranged with the first axial push rod 7, and the second axial The ejector rod 8 is installed in the docking base 1 thro...

Embodiment 2

[0043] Such as Figure 4 and Figure 5 As shown, a docking structure of an accelerometer watch core includes a first axial push rod 7, a second axial push rod 8, a first radial push plate 3, a second radial push plate 4, a first radial adjustment The rod 5 and the second radial adjustment rod 6; the docking base 1 is provided with a first sliding cavity 13 and a second sliding cavity 14 along the vertical direction.

[0044] The first axial push rod 7 passes through the side wall of the docking base 1 and is arranged in the axial direction of the watch movement 12 to be installed. The first axial push rod 7 is covered with a first mounting seat 9, and the first mounting seat 9 is installed on the docking In the first sliding cavity 13 in the base 1 , the first installation seat 9 is threadedly engaged with the first axial push rod 7 . The first mounting seat 9 is installed in the first sliding cavity 13, a second spring 15 is provided between the first mounting seat 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com