Servo device of trenching machine pipe coiling system

A technology of a follow-up device and a pipe system, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problem of large volume, unsatisfactory follow-up of the reducer drive device, and the spring drive device can not meet the construction requirements of deep groove operations. and other problems, to achieve the effect of small size, meeting the construction requirements of deep groove operation, and good effect of constant tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

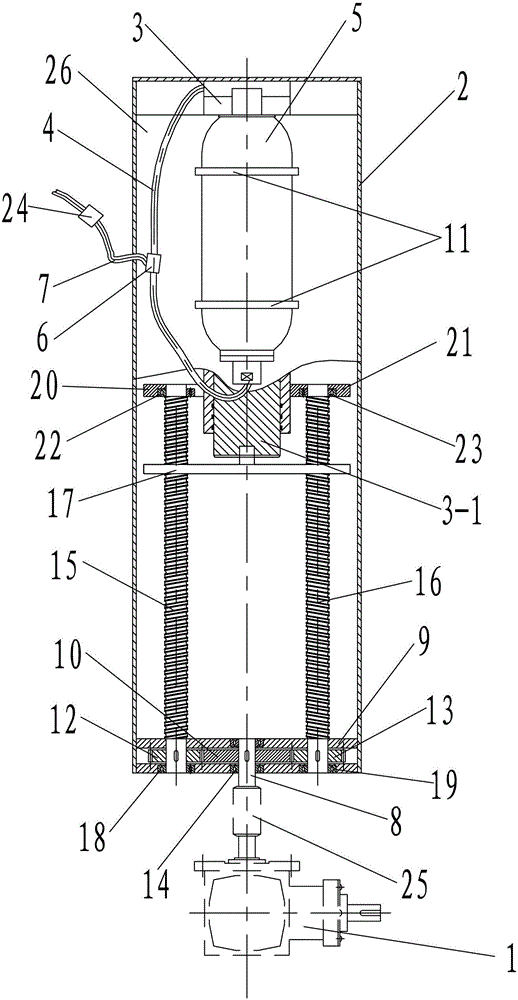

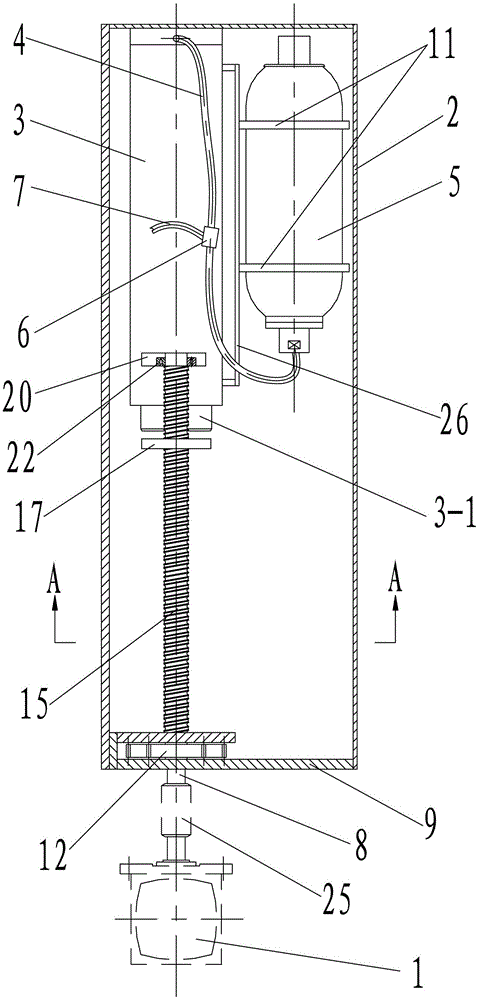

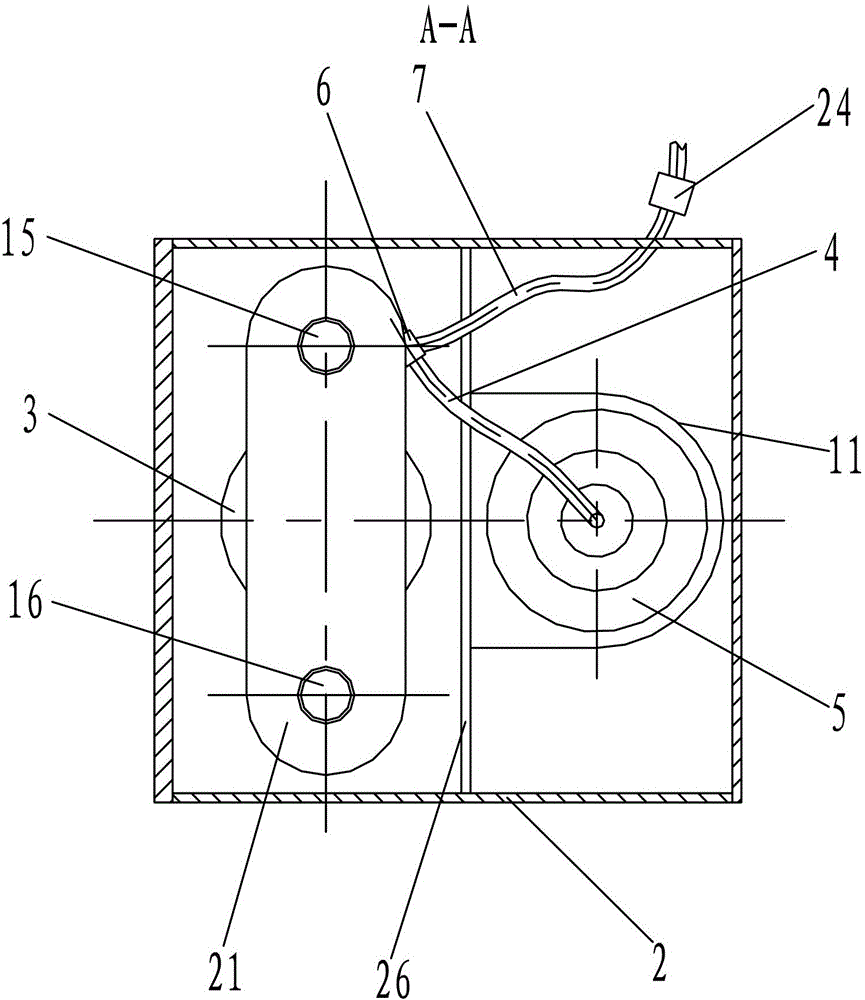

[0044] Such as figure 1 , figure 2 and image 3As shown, the present invention includes a reducer 1 fixedly connected to the hydraulic hose reel 31 in the groove forming machine and a constant tension control mechanism for providing constant tension for the hydraulic hose 30 in the groove forming machine, and for outputting the reducer 1 The power is transmitted to the constant tension control mechanism to realize the transmission mechanism of the hydraulic rubber hose 30 and the steel wire rope 28 in the slotting machine; The accumulator 5 connected to the oil cylinder 3, the first oil pipe 4 is connected with the second oil pipe 7 connected with the hydraulic oil tank in the groove forming machine through the tee joint 6; the transmission mechanism includes the output of the reducer 1 The transmission shaft 8 connected to the shaft, the gear transmission mechanism connected to the transmission shaft 8, and the gear transmission mechanism connected to the gear transmission...

Embodiment 2

[0056] combine Figure 5 The difference between this embodiment and Embodiment 1 is that the oil pressure controller includes a pressure sensor 24-3 and a solenoid valve 24-4 connected to the second oil pipe 7, and is used to control the pressure sensor 24-3 The detected signal is analyzed and processed and used for the controller module 24-5 that controls the solenoid valve 24-4 and the human-computer interaction device 24-6 connected with the controller module 24-5. The pressure sensor 24-3 It is connected with the input end of the controller module 24-5, and the solenoid valve 24-4 is connected with the output end of the controller module 24-5. All the other structures are the same as in Example 1.

[0057] During specific implementation, the controller module 24-5 may use a PLC module or a single-chip microcomputer, and the human-computer interaction device 24-6 may use a touch-type liquid crystal display.

[0058] When the present invention is used, it is different from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com