Negative pressure groove end face mechanical seal structure

A kind of end face mechanical seal and negative pressure technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of sealing air film disturbance, poor anti-interference ability, short service life, etc., to increase air film damping, Enhanced anti-jamming ability and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

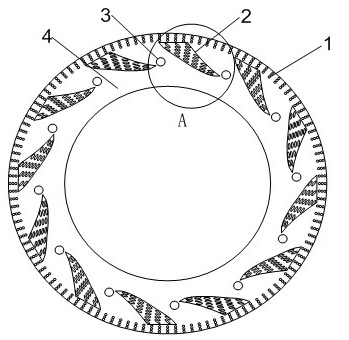

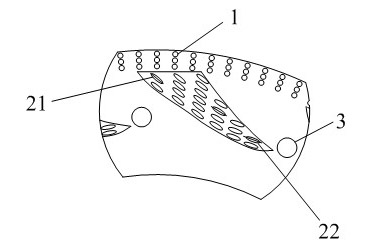

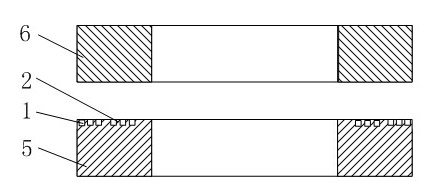

[0021] refer to Figure 1-3 , a negative pressure groove end face mechanical seal structure, including a moving ring 5 and a static ring 6 of a mechanical seal, one side of the end faces of the moving ring 5 and the static ring 6 is the high pressure side, that is, the upstream, the moving ring 5 and the The other side of the end surface of the static ring 6 is the low-pressure side, that is, the downstream side. The end surface of the moving ring 5 is provided with a negative pressure groove group symmetrically distributed according to the rotation center, and a microporous ring is arranged upstream of the negative pressure groove group. Belt 1, the negative pressure groove group is composed of spiral deformation inclination microporous dynamic pressure grooves 2 and decompression grooves 3 distributed at intervals, the decompression groove 3 is close to the end of the dynamic pressure groove 2, the negative pressure groove group The downstream is provided with a smooth plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com