Conveying roller way control device for producing corrugated paper through rolling temperature control

A technology of conveying roller table and control device, which is applied in the direction of machining/deformation, and can solve the problems of complex tension control structure, high center temperature, and low surface temperature of hot plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

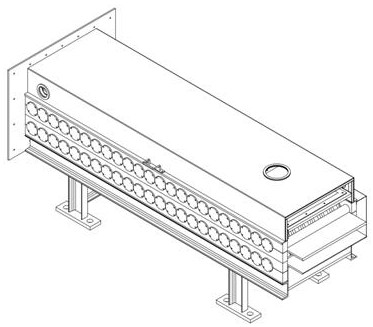

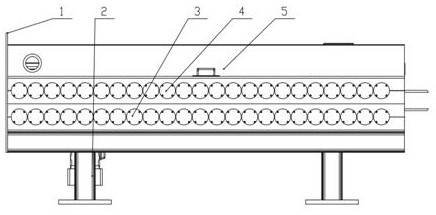

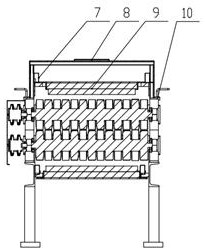

[0046] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0047] The roll pressure temperature control corrugated paper conveying roller table control device of the present invention includes a connection port 1, a bottom frame 2, a lower roller assembly 3, an upper roller assembly 4, a sealing cover 5, a frequency conversion deceleration motor 6, a hot air source pipeline 7, Exhaust port 8, resistance heater 9, roll gap adjustment bolt 10, roller table I 11, bearing end cover 12, bearing housing 13, bearing 14, shaft circlip 15, dustproof ring 16, bearing cover 17 , sprocket 18, sprocket pressure plate 19, fixing bolt 20, roller table II 20, guide plate 22. It is a production line equipment suitable for temperature control and speed control process of corrugated paper.

[0048] The connection port 1 is installed and fixed on the left side of the bottom frame 2, the lower roll assembly 3 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com