Tractor suspension force measuring device

A force measuring device and tractor technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of inaccurate measurement results, fixed measurement direction, etc., and achieve the effects of increasing reliability, improving accuracy, and weakening drastic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

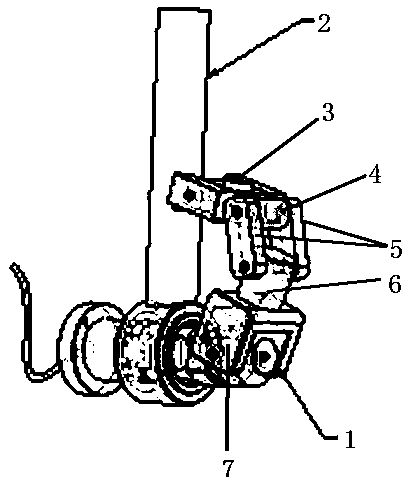

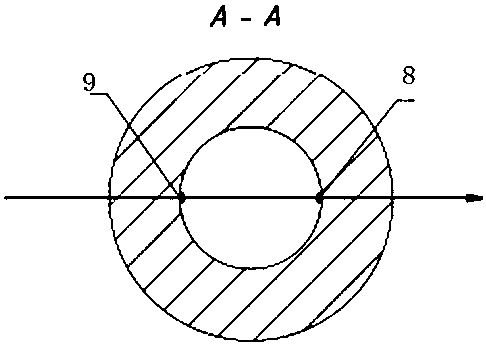

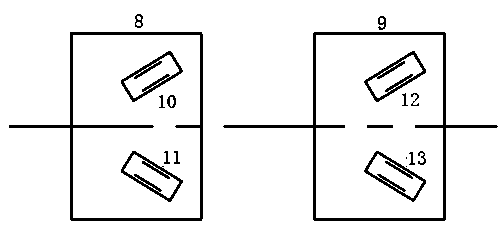

[0020] Such as figure 1 As shown, a tractor suspension force measuring device uses a pivot pin sensor 1 to measure the traction force, including a pivot pin and a Wheatstone bridge circuit.

[0021] A tractor three-point suspension force measuring device. Considering the convenience of installation and use, the pivot pin sensor 1 is installed at the hinge point between the three-point suspension pull rod 2 and the tractor body, and one end is connected to the front-end traction equipment through a universal joint coupling. One end is connected to the pull rod 2, the front-end traction device is a tractor, the rear-end device is a farm tool or other equipment that needs towing, and the pull rod 2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com