A method of cold extrusion wave shaping for curved parts

A technology of cold extrusion and arc-shaped parts, which is applied in the direction of metal extrusion dies, etc., can solve the problems of high shape and position accuracy, large internal stress of arc-shaped parts, and large springback, so as to improve forming accuracy and reduce springback deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

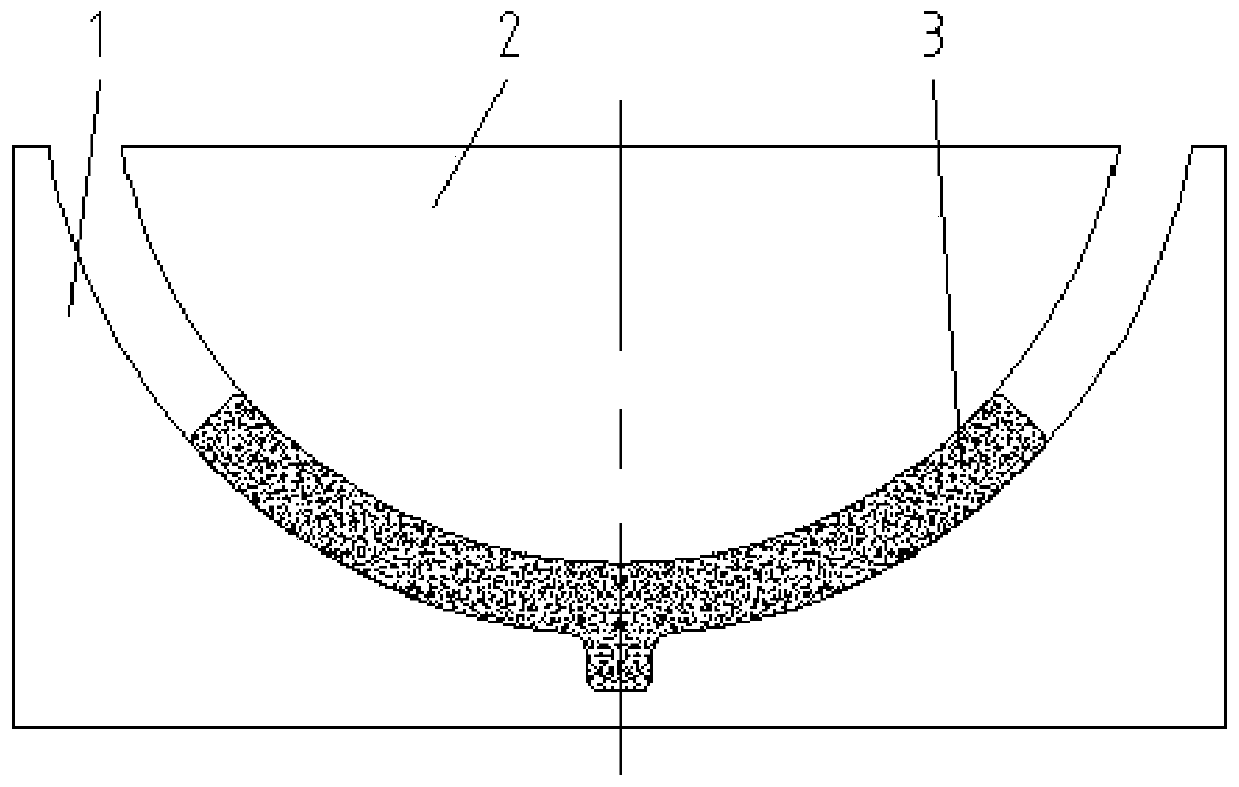

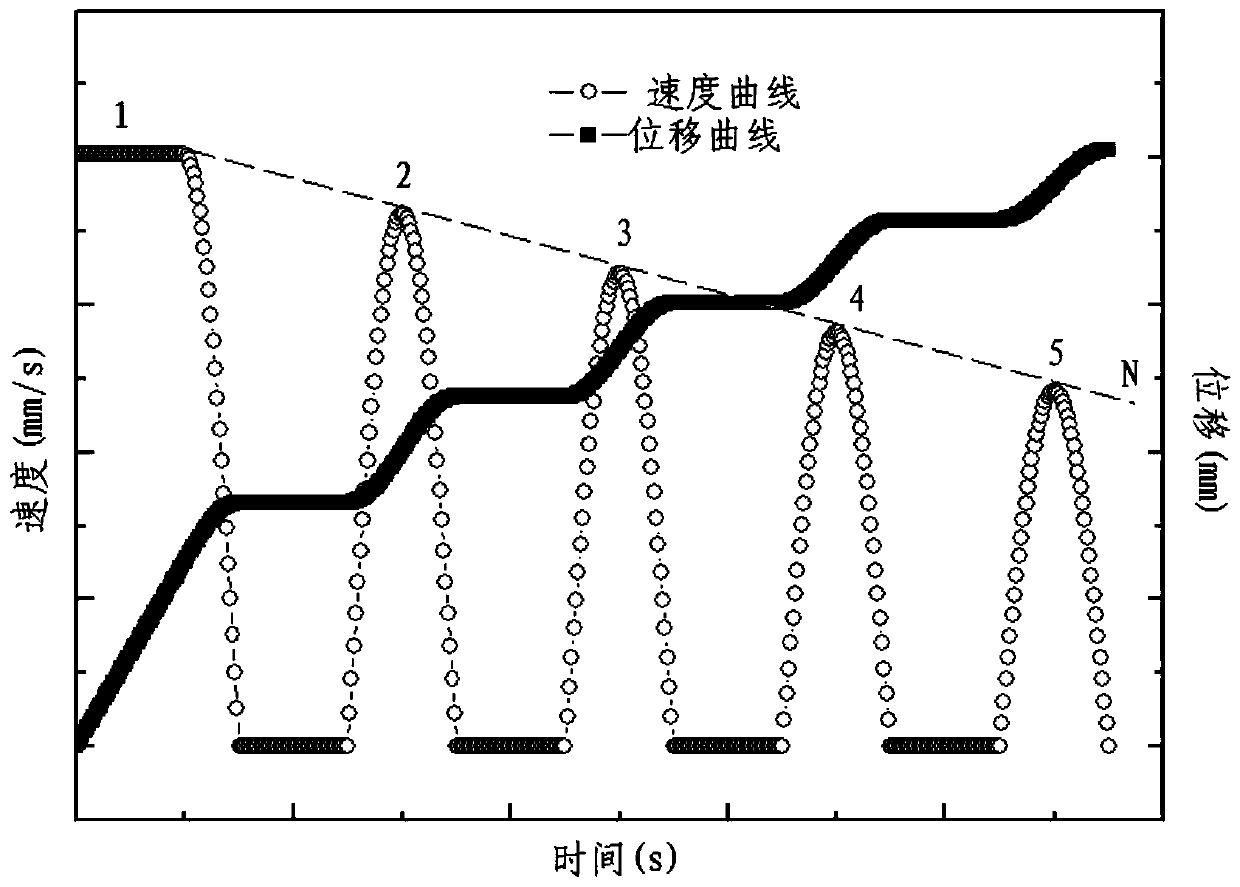

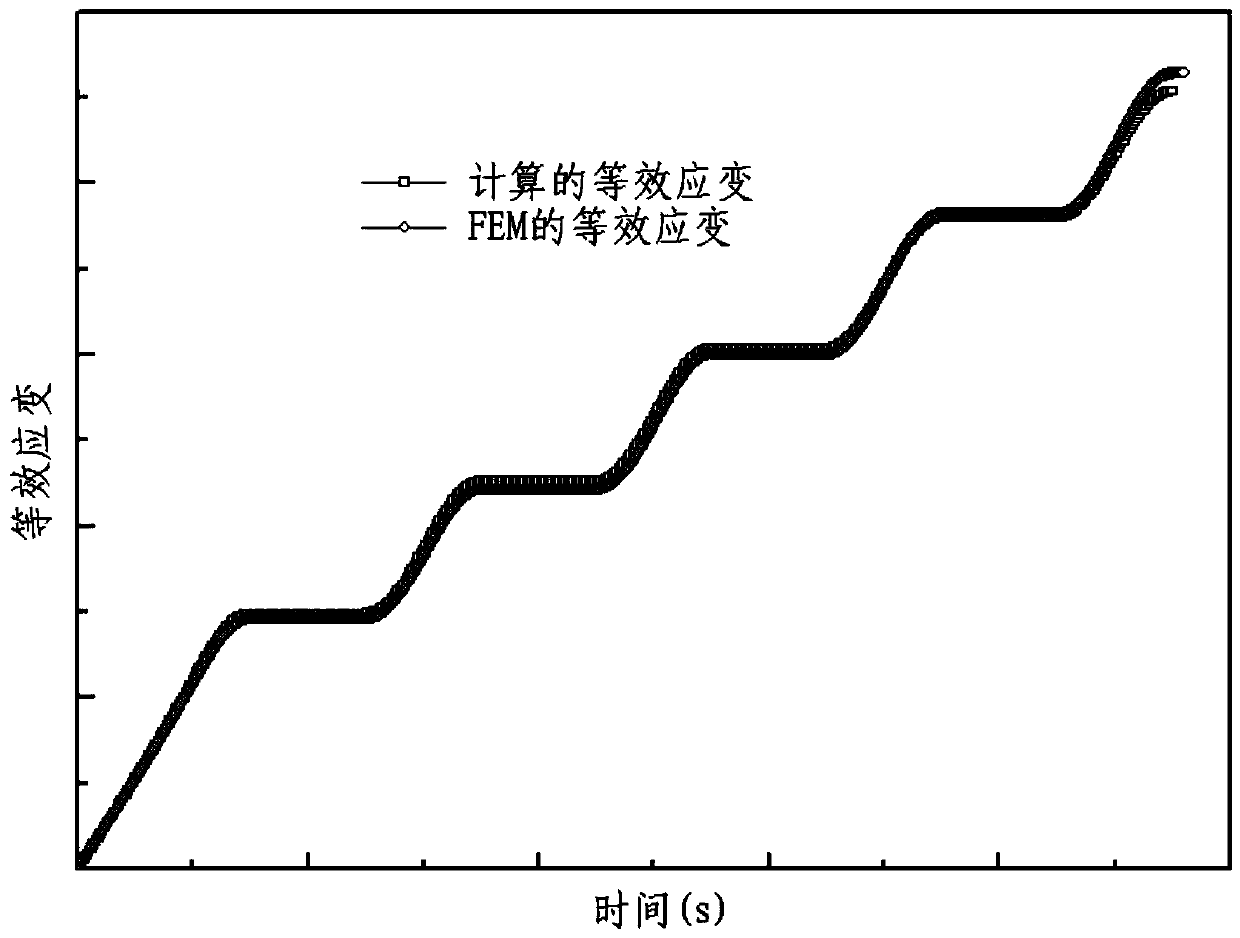

[0021] Taking the pure copper arc-shaped piece as the implementation object, the main body thickness of the blank is 4mm, and the cold extrusion shaping die is as follows: figure 1 As shown, the loading on the upper die of cold extrusion includes 10 periodic composite velocities, in which the amplitude of the fluctuating velocity in the adjacent effective plastic deformation cycle decreases from 0.2mm to 0.02mm in turn, and the fluctuating velocity frequency is 1.6 Hz, the number of discrete points is 100, and the loaded compound speed and trajectory are as follows figure 2 As shown in the figure, the upper mold sequentially performs multiple cycle forming on the billet downwards, such as accelerating loading, decelerating loading, and holding pressure. Using the same method, set the wave recombination speed in the finite element (FEM) simulation software, and import the pure copper material model to simulate and analyze the wave shaping process of cold extrusion of arc parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com