Wind power blade posterior-edge die spotting PVC foam design method

A wind turbine blade and design method technology, applied in the directions of calculation, geometric CAD, electrical digital data processing, etc., can solve the problems of high cost of PVC foam shape, long cycle, waste and pollution, etc., and achieve good operability, low cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

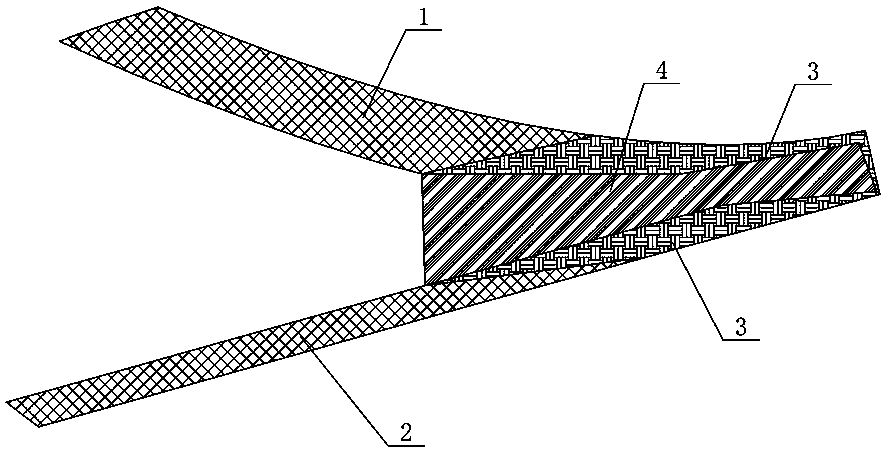

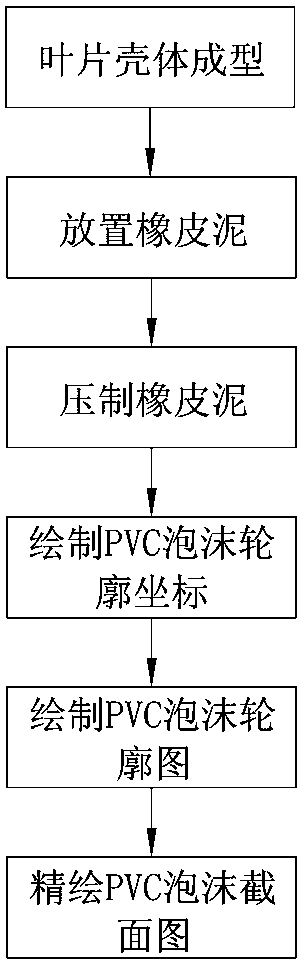

[0026] Figure 1 to Figure 3 A kind of embodiment of the PVC foam design method of wind power blade trailing edge clamping molding of the present invention is shown, comprising the following steps:

[0027] S1: Blade shell forming: According to the blade shell forming process, make the PS surface shell 1 and SS surface shell 2 of the shaped blade;

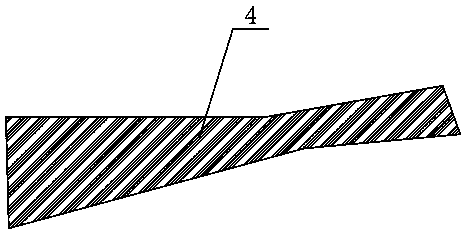

[0028] S2: Place the plasticine: place the plasticine 4 along the rear edge 3 of the SS surface, the plasticine 4 must run through the entire rear edge bonding surface, and the height of the plasticine 4 is higher than the height of the rear edge cavity;

[0029] S3: Press plasticine: Turn over the PS surface mold and lock it to obtain a plasticine compact that matches the cavity of the trailing edge of the blade, cut the plasticine 4 along the cross section, and obtain the cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com