Two-component organosilicone plasticine

A technology of plasticine and silicone, applied in the field of two-component curable silicone plasticine, which can solve the problems of complex production process and low content of dimethyl polysiloxane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

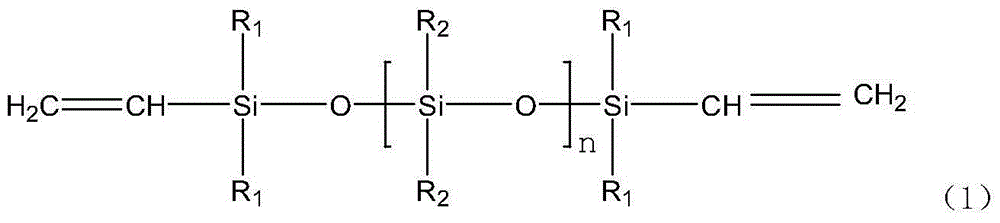

Method used

Image

Examples

Embodiment 1

[0016] 1. Preparation of two-component silicone plasticine A component:

[0017] Put 75 parts of methyl vinyl polysiloxane, 20 parts of filler, and 5 parts of silicone oil in a device with strong stirring, mix and stir, raise the temperature to 160 ° C for 1.5 hours, and then lower it to room temperature to obtain the base; then Put 98 parts of the base material, 1.5 parts of the pigment and 0.5 parts of the catalyst in a mixer, and mix them uniformly to prepare the A component.

[0018] 2. Preparation of two-component silicone plasticine B component:

[0019] Put 76 parts of methyl vinyl polysiloxane, 20 parts of filler, and 4 parts of silicone oil in a mixer, mix and stir, raise the temperature to 170°C for 2 hours, and then cool down to room temperature to obtain the base; mix 97 parts of the base, Put 1.5 parts of pigment, 1.2 parts of cross-linking agent, and 0.3 parts of speed control agent into the mixer, mix well and make component B evenly.

[0020] 3. Prepare test ...

Embodiment 2

[0023] 1. Preparation of two-component silicone plasticine A component:

[0024] Put 80 parts of methyl vinyl polysiloxane, 17 parts of filler, and 3 parts of silicone oil in a device with strong stirring, mix and stir, raise the temperature to 150 ° C for 2 hours, and then lower it to room temperature to obtain the base; then Put 97 parts of the base material, 1.5 parts of the pigment, and 0.5 parts of the catalyst into a mixer, and mix them uniformly to prepare component A.

[0025] 2. Preparation of two-component silicone plasticine B component:

[0026] Put 80 parts of methyl vinyl polysiloxane, 18 parts of filler, and 2 parts of silicone oil in a mixer, mix and stir, raise the temperature to 170 ° C for 2 hours, and then cool down to room temperature to obtain the base; mix 98 parts of the base, Put 0.5 parts of pigment, 1.2 parts of cross-linking agent, and 0.3 parts of speed control agent into the mixer, mix well and make component B evenly.

[0027] 3. Prepare test s...

Embodiment 3

[0030] 1. Preparation of two-component silicone plasticine A component:

[0031] Put 65 parts of methyl vinyl polysiloxane, 32 parts of filler, and 3 parts of silicone oil in a device with strong stirring, mix and stir, raise the temperature to 160 ° C for 1.5 hours, and then lower it to room temperature to obtain the base; then Put 98 parts of the base material, 1.5 parts of the pigment and 0.5 parts of the catalyst in a mixer, and mix them uniformly to prepare the A component.

[0032] 2. Preparation of two-component silicone plasticine B component:

[0033] Put 65 parts of methyl vinyl polysiloxane, 30 parts of filler, and 5 parts of silicone oil in a mixer, mix and stir, raise the temperature to 170°C for 2 hours, and then cool down to room temperature to obtain the base; mix 97 parts of the base, Put 1.5 parts of pigment, 1.2 parts of cross-linking agent, and 0.3 parts of speed control agent into the mixer, mix well and make component B evenly.

[0034] 3. Prepare test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com