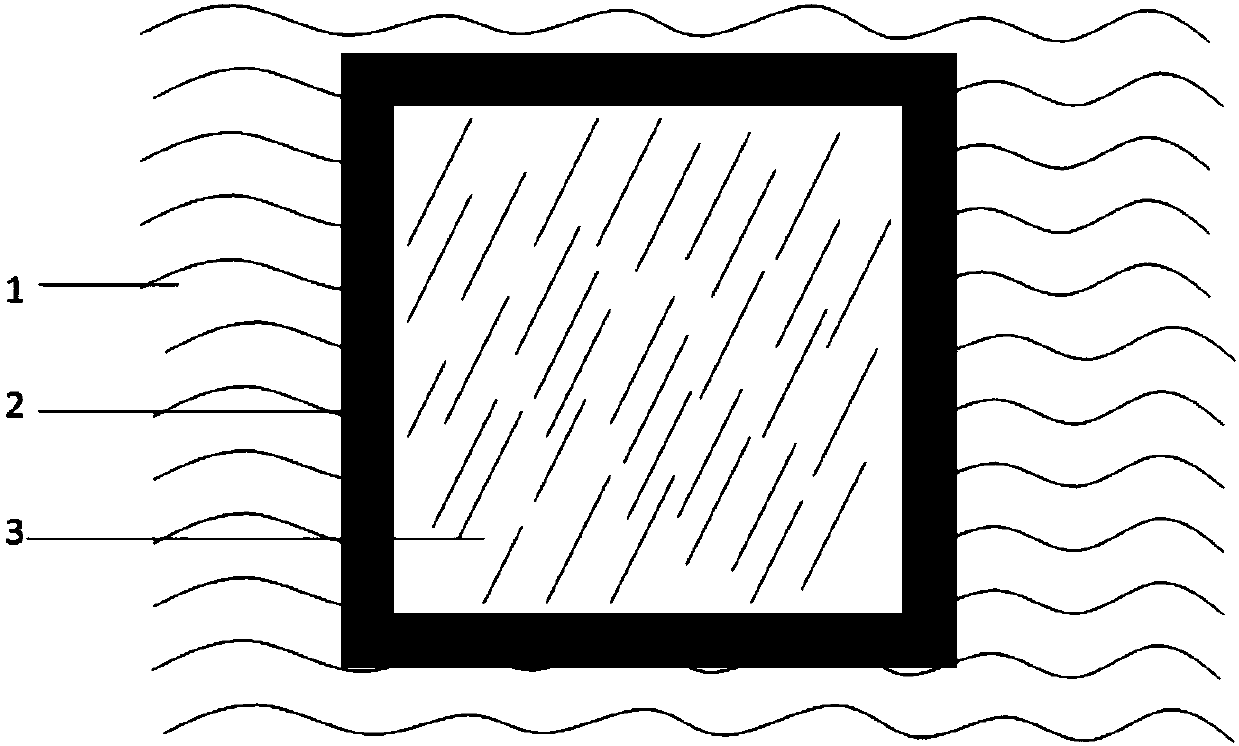

Roughness detecting method for combined surface of concrete prefabricated part

A technology of prefabricated components and detection methods, applied in the direction of measuring devices, instruments, etc., can solve the problem that the sand filling method cannot be applied to non-horizontal surfaces, and achieve the effect of increasing speed and stable and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

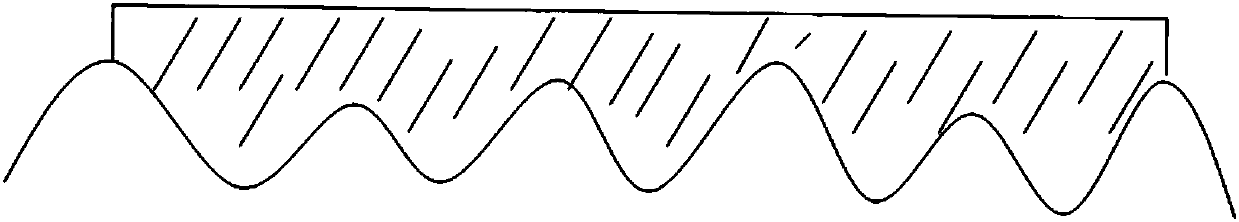

Method used

Image

Examples

Embodiment 1

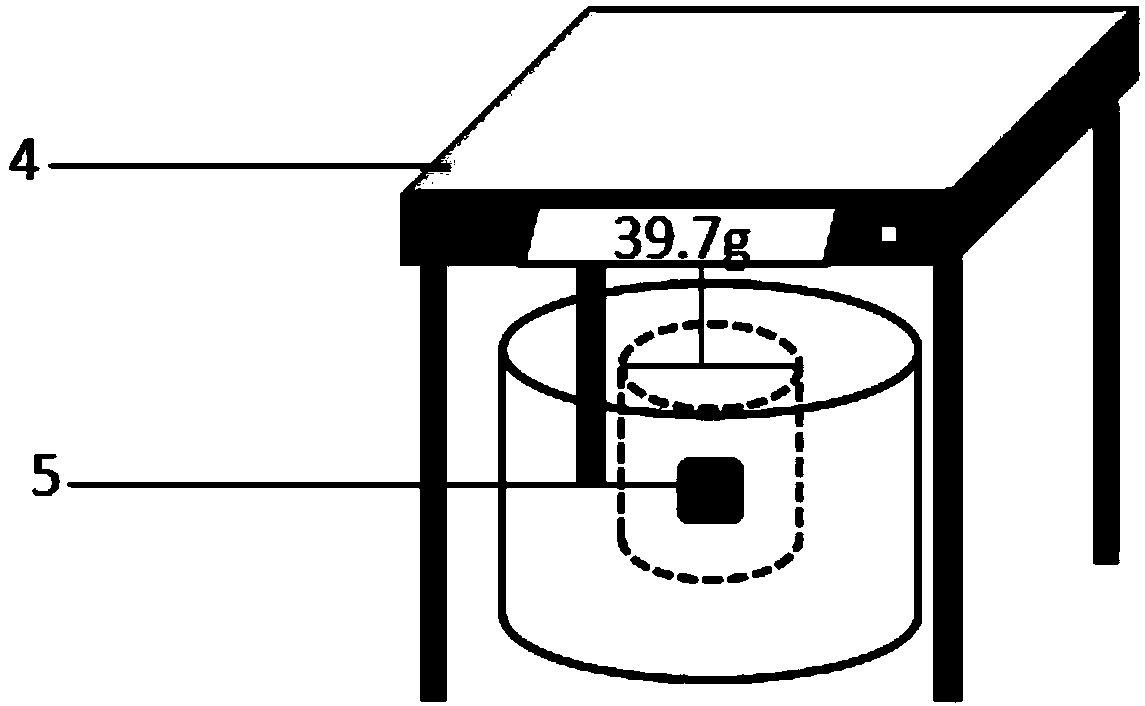

[0035] Randomly select 10 areas on the joint surface of a concrete component, apply a layer of release oil to the selected area, and fix the stainless steel frame in this area; fill the stainless steel frame with plasticine until it is flush with the surface of the frame In this process, it can be squeezed by hand to ensure that the unevenness of the surface of the component is filled with plasticine, and the excess plasticine is removed with a spatula; remove the stainless steel frame, remove the plasticine attached to the surface of the component, and use a hydrostatic balance 4 its weight in air m 1 , accurate to 0.01g, then put the plasticine in the basket and put them in distilled water together, and weigh the mass of the plasticine in water with a hydrostatic balance 4 m 2 Accurate to 0.01g. The obtained data and results are shown in Table 1 below:

[0036] Table 1 uses plasticine to test the surface roughness of concrete (mm)

[0037]

[0038] It can be seen from ...

Embodiment 2

[0040] Randomly select 10 areas on the joint surface of a concrete component, apply a layer of release oil to the selected area, and fix the stainless steel frame in this area; fill the stainless steel frame with plasticine until it is flush with the surface of the frame In this process, it can be squeezed by hand to ensure that the unevenness of the surface of the component is filled with plasticine, and the excess plasticine is removed with a spatula; remove the stainless steel frame, remove the plasticine attached to the surface of the component, and use a hydrostatic balance 4 its weight in air m 1 , accurate to 0.01g, then put the plasticine in the basket and put them in distilled water together, and weigh the mass of the plasticine in water with a hydrostatic balance 4 m 2 Accurate to 0.01g. The obtained data and results are shown in Table 2 below:

[0041] Table 2 uses plasticine to test the surface roughness of concrete (mm)

[0042]

[0043] It can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com