Rock fracture shear seepage test device and test method thereof

A technology for rock fissures and test devices, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. Analytical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

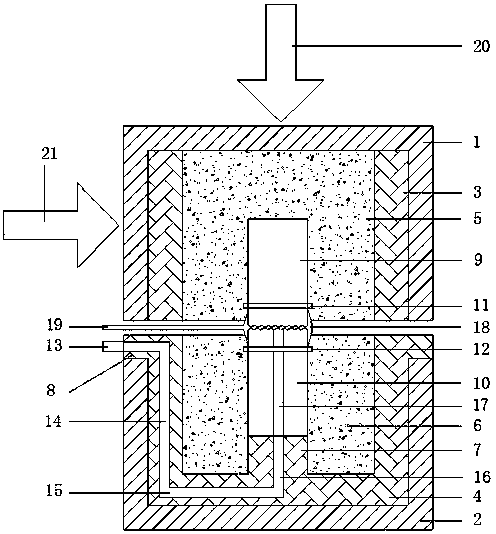

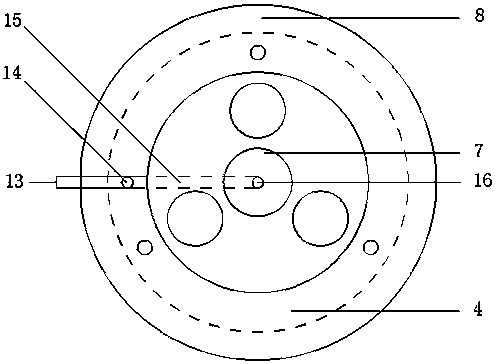

[0022] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: a rock fissure shear seepage test device, including four systems of loading control system, measurement system, fluid source loading system, shear box and its sealing system, the loading control system It uses the loading control system in the RD200 shear instrument produced by GCTS, which can provide normal load 20 and shear load 21 loading methods, and can control the whole process of the test in real time through the control system.

[0023] The measurement system includes the measurement of load and rock mass crack displacement during normal loading, the measurement of load and rock mass crack displacement during shear loading, and the measurement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com