Processing technology of silicon rubber mould

A mold manufacturing and silicone rubber technology, applied in the field of silicone rubber mold manufacturing technology, can solve problems such as material waste, achieve the effects of being less prone to damage, improving life, and overcoming quality problems of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

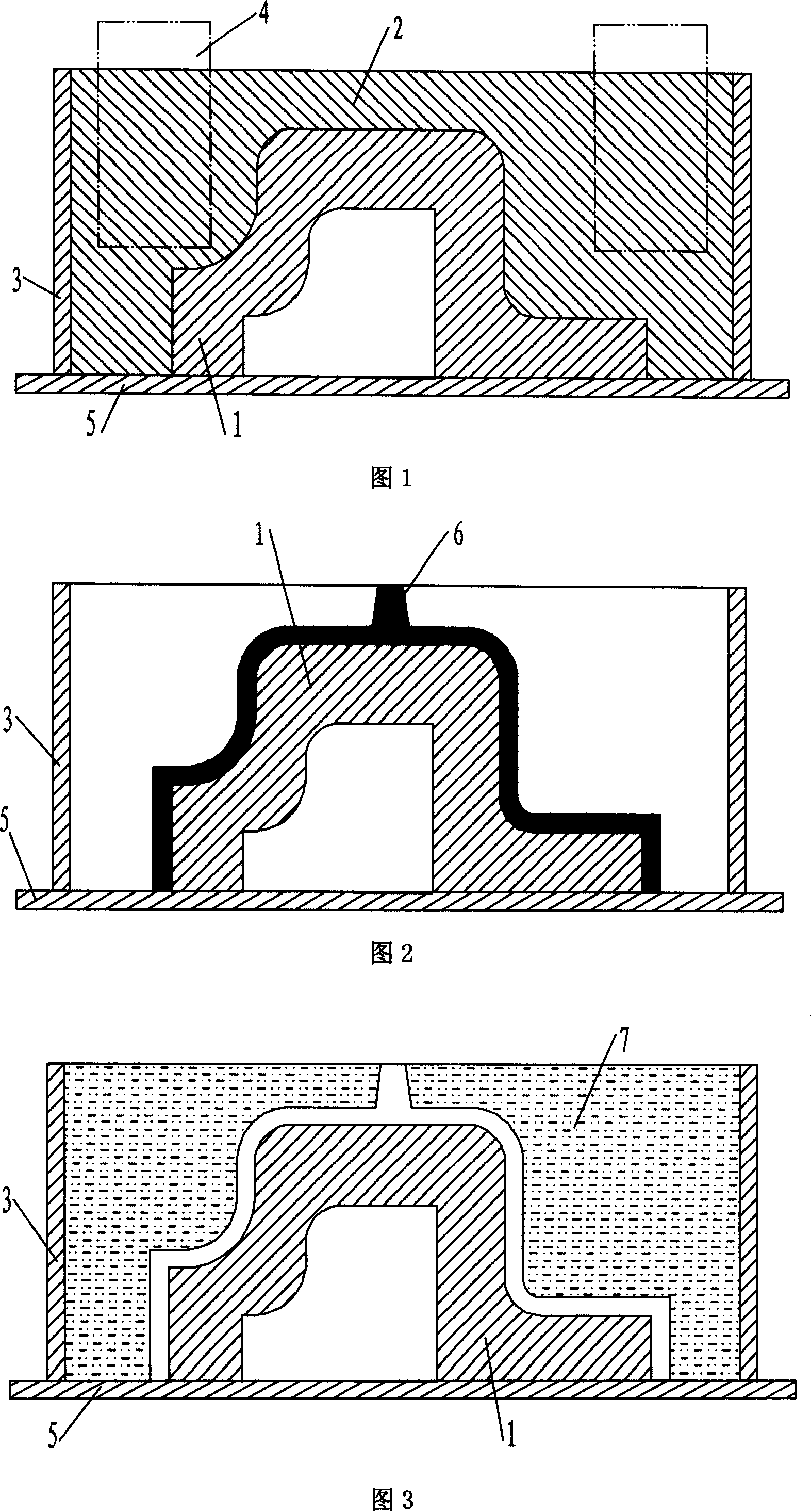

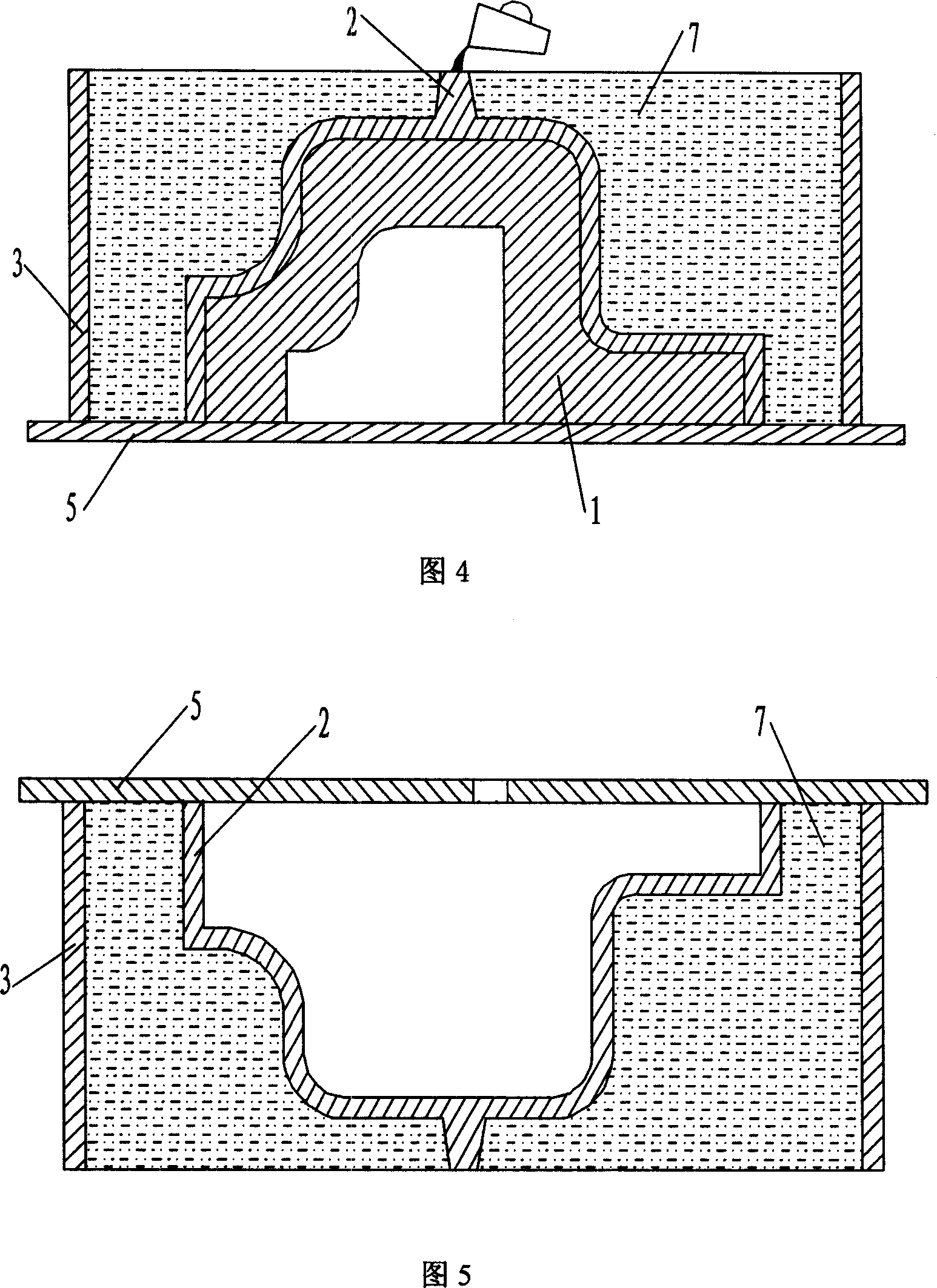

[0021] The technological process of the present invention is: sample prototype (can be manufactured by rapid prototyping technology)—type processing—paste clay or plasticine—build the mold frame—mix gypsum slurry—gypsum molding—remove clay—cast silicone rubber—silicone rubber vulcanization — Take out the prototype and process the cavity.

[0022] The specific process is as follows:

[0023] 1. As shown in Figure 2, carry out the necessary surface cleaning and smoothing treatment on the sample prototype 1, and fix the sample prototype on the flat plate 5, stick clay or plasticine 6 on the surface of the sample prototype, clay or plasticine 6 It can also be replaced by hot-melt materials, and the thickness of the paste is generally about 10mm. According to the overall size of the mold and the minimum wall thickness requirements, a mold frame 3 of a half mold is made on the flat plate 5 .

[0024] 2. As shown in Figure 3, mix gypsum powder and water evenly according to a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com