Polishing grinding disc for restraining full-band error of optical surface

A technology for polishing grinding discs and optical surfaces, which is applied to optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve problems such as complex finite element analysis, limited wide application, and cumbersome optical components, so as to increase the amount of grinding removal, Eliminate the effect of rotation conduction and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

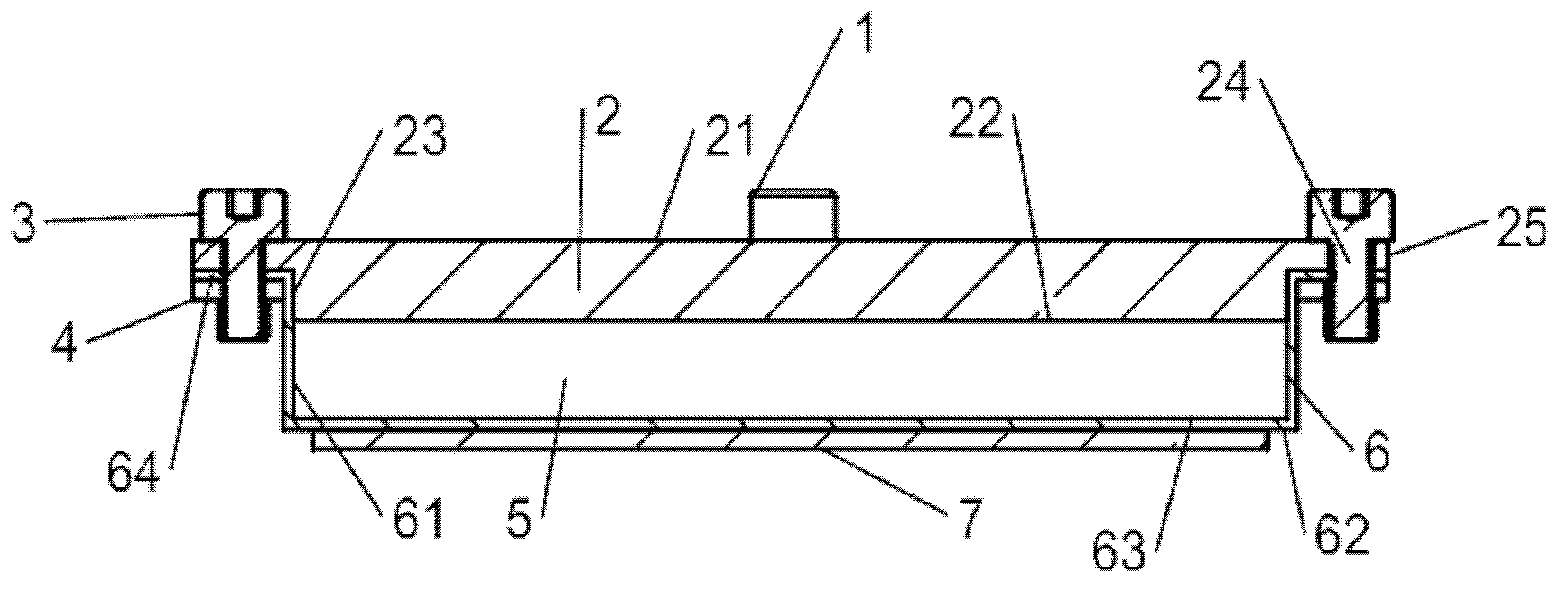

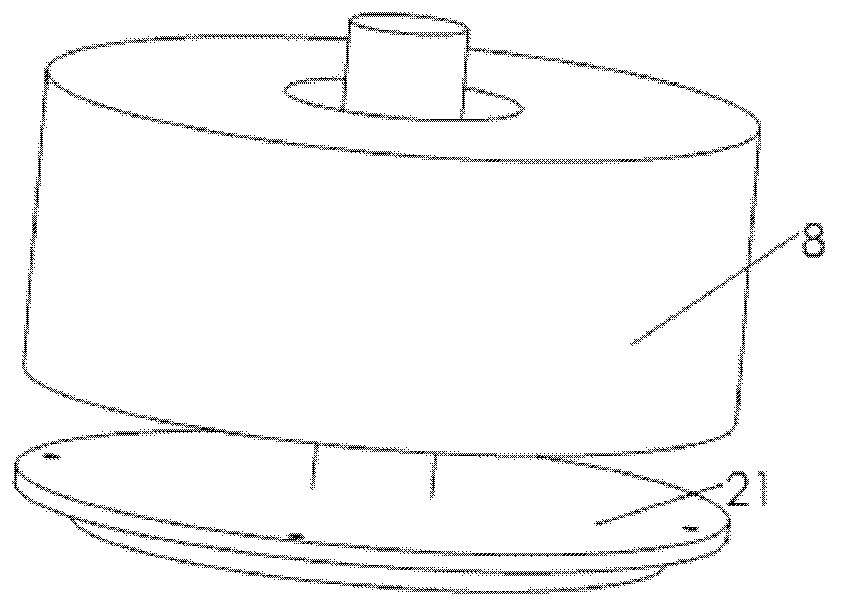

[0033] refer to figure 1 , a polishing disc for suppressing the full-frequency error of the optical surface, comprising a shaft connection end 1, a base 2, a bolt 3, a flange ring 4, a magnetorheological plasticine 5, a diaphragm sealing diaphragm 6, a polishing layer 7, and a magnetic field generator 8; where:

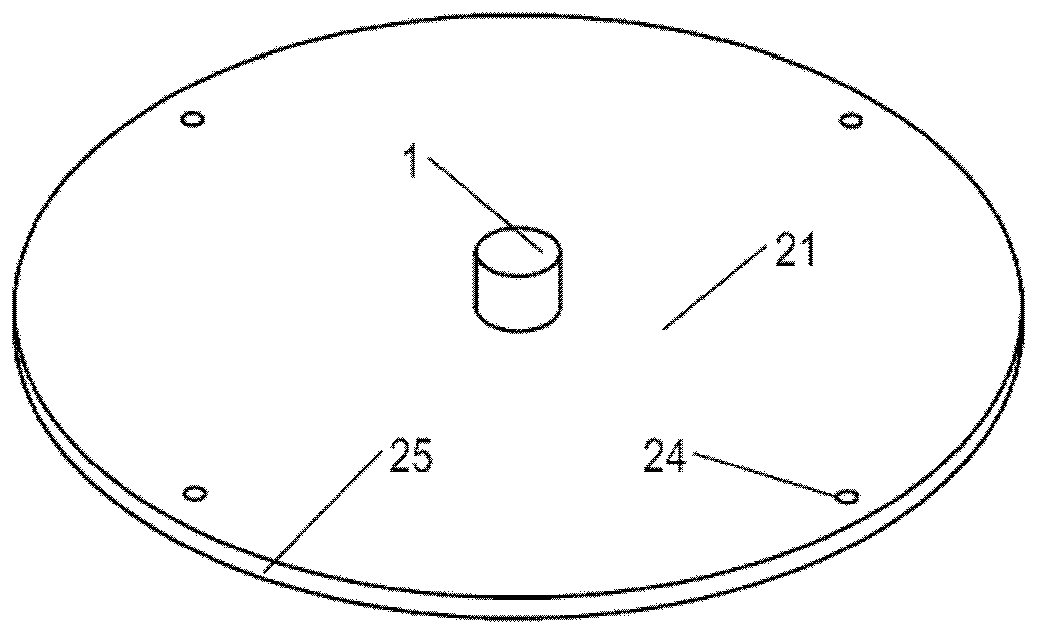

[0034] The connecting end 1 of the rotating shaft is located at the center of the outer upper part 21 of the base, and is used to connect the power output rotating shaft of the machine tool to obtain the driving force to drive the entire polishing disc of the present invention to rotate;

[0035] The base 2 is a cylinder with an outer upper part 21, an outer lower part 22, a side wall 23, a fixed screw hole 24 and an annular boss 25; the annular boss 25 is located outside the side wall 23, and the annular boss 25 has a set of Connect the screw holes 24, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com