Plasticine and preparation method and reusable sand table using plasticine

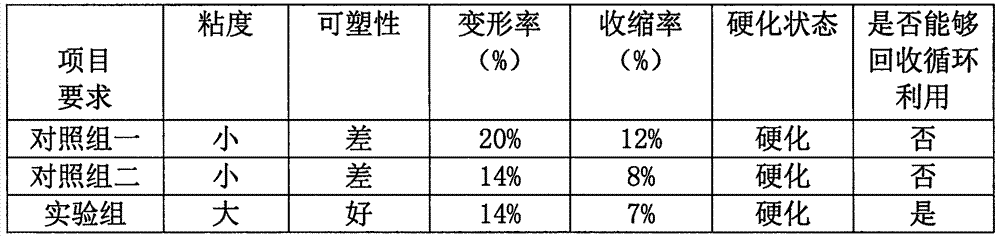

A plasticine and model technology, applied in the field of environmental art, can solve the problems of non-recyclability and high cost of sand table production, and achieve the effects of not easy to deform, low hardening and shrinkage, and convenient for recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention is a kind of plasticine and its preparation method and the recyclable sand table using the plasticine, wherein the plasticine comprises:

[0025] (1) A plasticine, which comprises the following raw materials in parts by weight: 20-28 parts of xanthan gum, 11-15 parts of glycerol, 20-24 parts of gum arabic, 9- 13 parts, 10-14 parts of isopropanol, 5-9 parts of titanium dioxide, 20-28 parts of konjac flour, 6-10 parts of clay, 11-13 parts of liquid paraffin, 3-5 parts of palm oil, 2- 4 parts, 3-5 parts of silicone oil, 4-6 parts of organic silicon quaternary ammonium salt, 4-6 parts of sodium citrate and 30-36 parts of deionized water.

[0026] (2) A plasticine, which comprises the following raw materials in parts by weight: 28 parts of xanthan gum, 11 parts of glycerin, 22 parts of gum arabic, 10 parts of sodium tripolyphosphate, 11 parts of isopropanol , 9 parts of titanium dioxide, 28 parts of konjac flour, 8 parts of clay, 11 parts of liquid par...

Embodiment 1

[0039] A plasticine, which comprises the following raw materials in parts by weight: 20 parts of xanthan gum, 11 parts of glycerol, 20 parts of gum arabic, 9 parts of sodium tripolyphosphate, 10 parts of isopropanol, titanium dioxide 5 parts, konjac flour 20 parts, clay 6 parts, liquid paraffin 11 parts, palm oil 3 parts, acetyl chitin 2 parts, silicone oil 3 parts, silicone quaternary ammonium salt 4 parts, sodium citrate 4 parts and deionized water 30 parts .

[0040] A preparation method of plasticine, comprises the steps:

[0041] 1) Take deionized water and pour it into the internal mixer, heat it through the internal mixer for 10 minutes, so that the temperature of the deionized water is raised to 70 ° C, then take xanthan gum and gum arabic and add it to the internal mixer at the same time with the heated deionized Water is mixed, and start internal mixer to rotate with the rotating speed of 30r / pm, make xanthan gum and carrageenan dissolve in deionized water, make gel...

Embodiment 2

[0049] A plasticine, which comprises the following raw materials in parts by weight: 28 parts of xanthan gum, 15 parts of glycerol, 24 parts of gum arabic, 13 parts of sodium tripolyphosphate, 14 parts of isopropanol, titanium dioxide 9 parts, konjac flour 28 parts, clay 10 parts, liquid paraffin 13 parts, palm oil 5 parts, acetyl chitin 4 parts, silicone oil 5 parts, silicone quaternary ammonium salt 6 parts, sodium citrate 6 parts and deionized water 36 parts share.

[0050] A preparation method of plasticine, comprises the steps:

[0051] 1) Take deionized water and pour it into the internal mixer, heat it through the internal mixer for 10 minutes, so that the temperature of the deionized water is raised to 70 ° C, then take xanthan gum and gum arabic and add it to the internal mixer at the same time with the heated deionized Water is mixed, and start internal mixer to rotate with the rotating speed of 30r / pm, make xanthan gum and carrageenan dissolve in deionized water, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com