Adjustable tweezers for multi-hole anti-skidding sleeves

A non-slip sleeve and porous technology, which is applied in the field of adjustable tweezers with porous anti-slip sleeves, can solve problems such as non-standard, affect the user's use effect, and the position cannot be moved, and achieve the effect of meeting the anti-slip needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

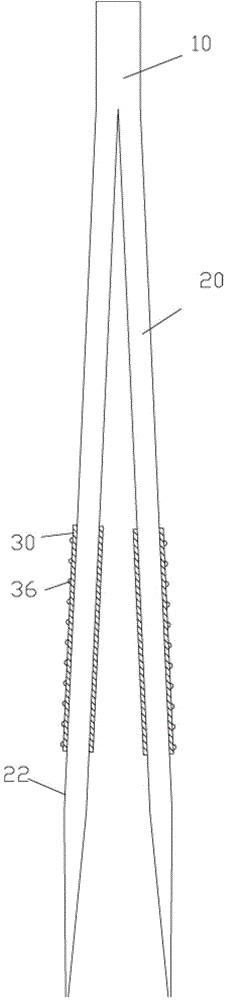

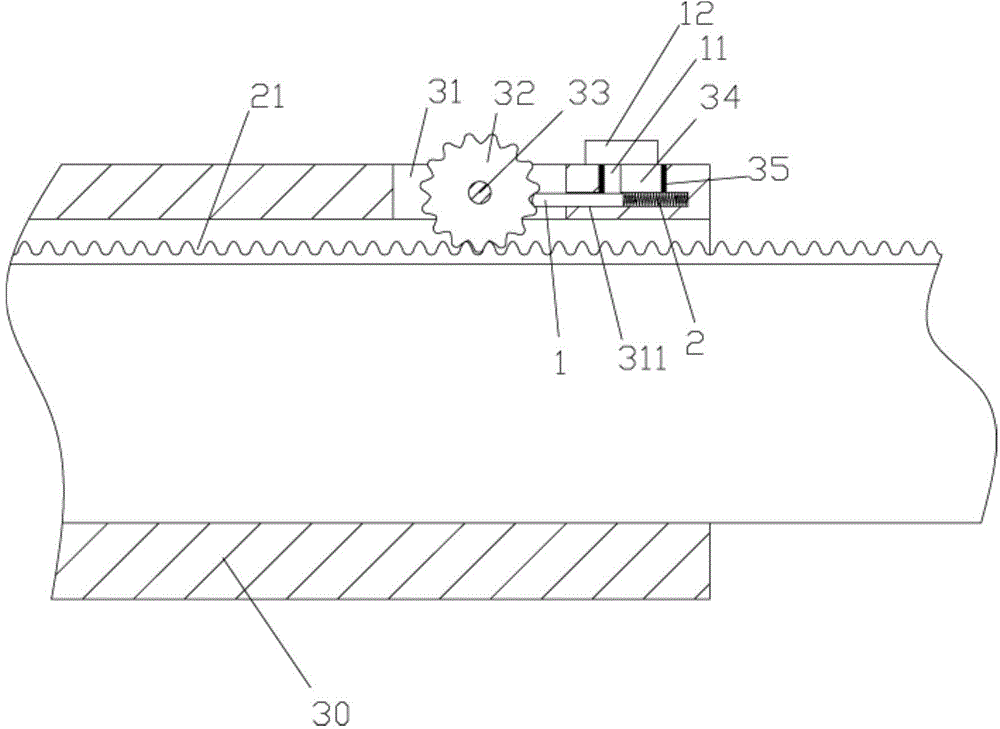

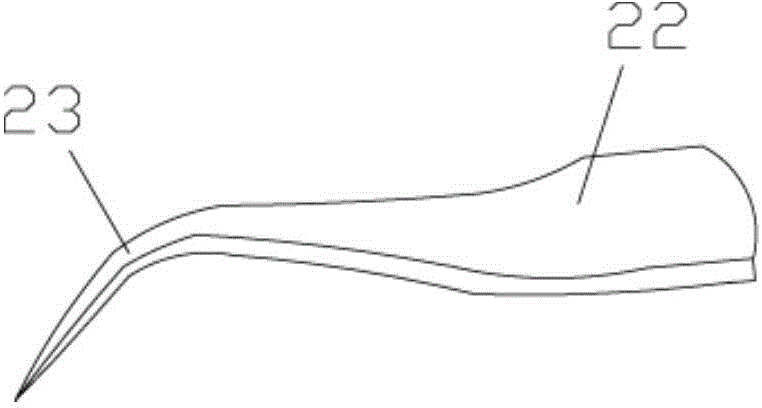

[0022] Examples, see e.g. Figures 1 to 6 As shown, a porous anti-slip sleeve adjustable tweezers includes a body, the body includes a connecting portion 10 and a tweezer arm 20, the connecting portion 10 has a plurality of stepped through holes 101, and the large diameter section of the stepped through hole 101 There are at least two opposite transverse insertion holes 102 on the inner side wall of the position, and the locking spring 103 and the steel ball 104 are inserted in the transverse insertion holes 102, and the transverse insertion hole 102 is close to the inner side wall of the large diameter section of the stepped through hole 101 The limiting plate 105 is fixed, the middle part of the limiting plate 105 has a middle through hole 106, the steel ball 104 is inserted into the middle through hole 106, the front part of the steel ball 104 protrudes from the middle through hole 106, and one end of the locking spring 103 exerts force The bottom end of the horizontal inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com