Method for preparing deep-fried collagen casings by wet soaking

A collagen casing and frying technology, which is applied in sausage casings, slaughtering, food science and other directions, can solve the problems of aluminum human health hazards, aluminum food pollution, pollution and other problems, and achieve the effects of simple and easy production, elimination of peculiar smell, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

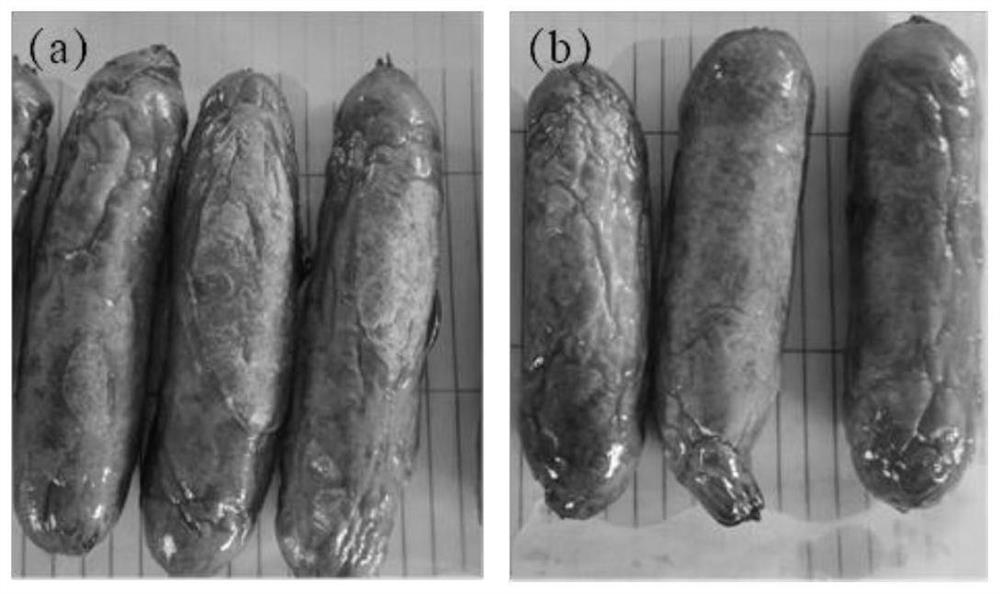

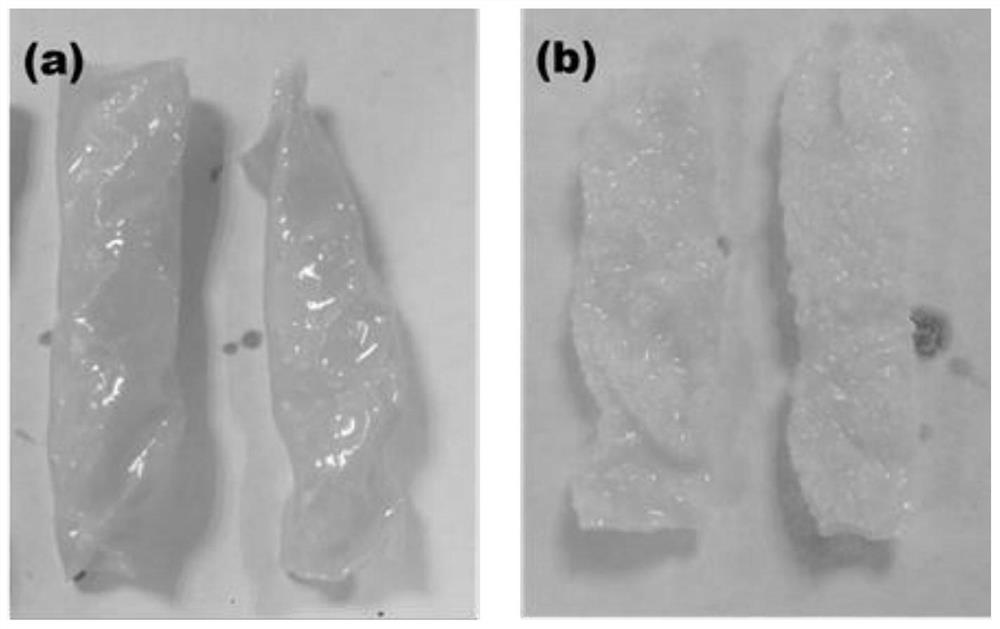

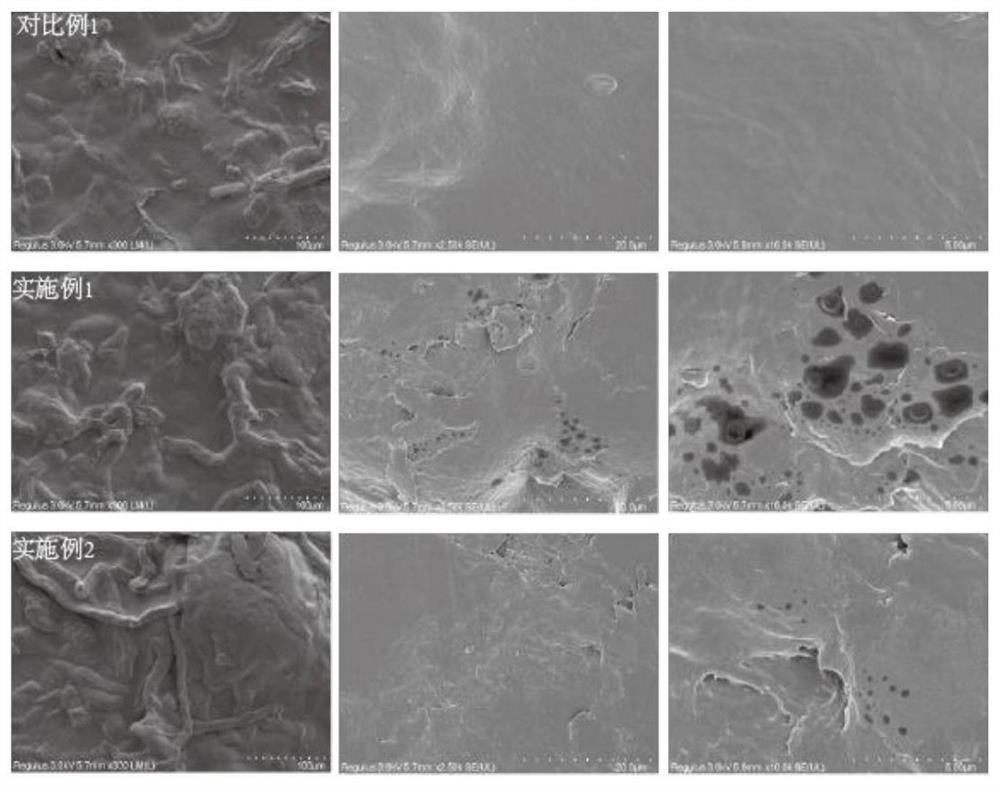

[0041] The oil-fried collagen casing was prepared by wet immersion, as follows:

[0042] (1) Preparation of Bullithm: Bullocate the pretreated cattle 2 layers, cutting 7 min at a high speed pulverizer, and adding threshing ice to control the temperature at 13 ° C;

[0043] (2) Preparation of mixed acids: 0.36 wt% hydrochloric acid solution, add 2.3 wt% cork, hydrochloric acid solution, mix well to obtain an acid mixture;

[0044] (3) Preparation of colon group: mixed with a maternal mixture prepared in (2) with a leather pulp in (1) to prepare collagen group, stored at 8 ° C for 18 h;

[0045] (4) Extrusion curing: After the collagen group is filtered under 30 MPa pressure, the rotation speed is 20 rpm extruded machine extrusion, venting air and ammonia gas, the pressure is 20 psi, the temperature is at room temperature, the temperature is 2 min ;

[0046] (5) Crosslinking water: The cured casing passes through the crosslinked soaking pool; the crosslinking time is 30 min; the cro...

Embodiment 2

[0051] The oil-fried collagen casing was prepared by wet immersion, as follows:

[0052] (1) Preparation of Bullithm: Bullocate the pretreated cattle 2 layers, cutting 7 min at a high speed pulverizer, and adding threshing ice to control the temperature at 13 ° C;

[0053] (2) Preparation of mixed acids: formulated 0.36 wt% HCl solution, add 2.3 wt% cork fibril to HCl solution and mix well to obtain an acid mixture;

[0054] (3) Preparation of colon group: mixed with a maternal mixture prepared in (2) with a leather pulp in (1) to prepare collagen group, stored at 8 ° C for 18 h;

[0055] (4) Extrusion curing: After the collagen group is filtered under 30 MPa pressure, the rotation speed is 20 rpm extruded machine extrusion, venting air and ammonia gas, the pressure is 20 psi, the temperature is at room temperature, the temperature is 2 min ;

[0056] (5) Crosslinking water: The cured casing passes through the crosslinked soaking pool; the crosslinking time is 30 min; the crosslin...

Embodiment 3

[0061] The oil-fried collagen casing was prepared by wet immersion, as follows:

[0062] (1) Preparation of Bullithm: Bullocate the pretreated cattle 2 layers, cutting 7 min at a high speed pulverizer, and adding threshing ice to control the temperature at 13 ° C;

[0063] (2) Preparation of mixed acids: formulated 0.36 wt% HCl solution, add 2.3 wt% cork fibril to HCl solution and mix well to obtain an acid mixture;

[0064] (3) Preparation of colon group: mixed with a maternal mixture prepared in (2) with a leather pulp in (1) to prepare collagen group, stored at 8 ° C for 18 h;

[0065] (4) Extrusion curing: After the collagen group is filtered under 30 MPa pressure, the rotation speed is 20 rpm extruded machine extrusion, venting air and ammonia gas, the pressure is 20 psi, the temperature is at room temperature, the temperature is 2 min ;

[0066] (5) Crosslinking water: The cured casing passes through the crosslinked soaking pool; the crosslinking time is 30 min; the crosslin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com