High-strength and high-water-permeation water permeable bricks and preparation technology thereof

A technology of permeable bricks and cement, which is applied to pavements paved with prefabricated blocks, pavement details, buildings, etc. It can solve problems such as deformation and cracking, resin-based permeable bricks are easy to age, and poor water permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

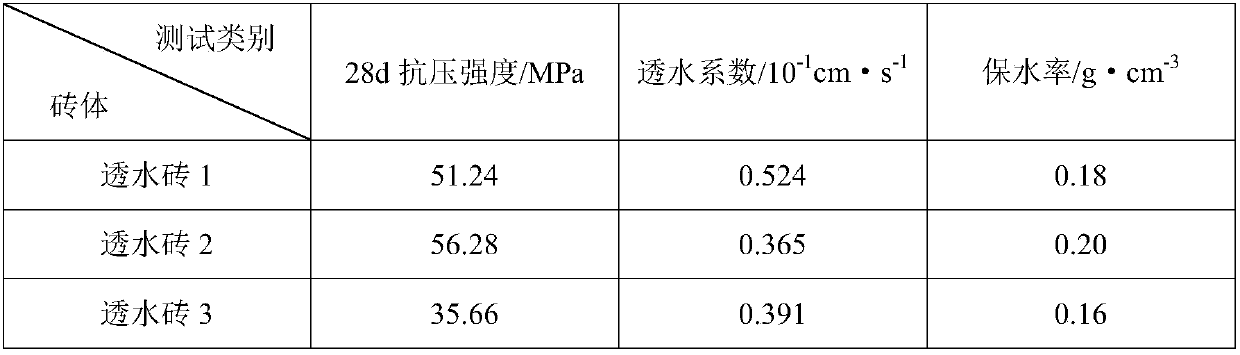

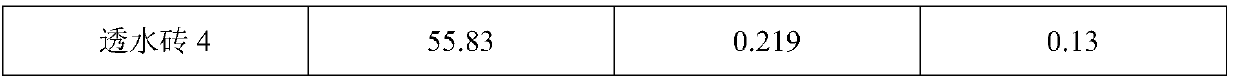

Examples

Embodiment 1

[0028] (1) Configure each raw material according to the following ratio:

[0029] Configure the bottom material: take 450kg of conventional cement, 1332kg of stones with a particle size of 3-8cm, and 8kg of reinforcing agent.

[0030] Configure surface materials: take 63kg white cement, 81kg black sand, 252kg white sand with a particle size of 40-80, and 0.92kg reinforcing agent.

[0031] (2) Mixing: vibrate and mix the stones required for the bottom layer materials and the cement conveyed by the screw conveyor, add the reinforcing agent and send them to the molding machine through the belt conveyor after the mixing is completed; the black sand required for the surface layer materials , White sand is mixed evenly, and the cement conveyed by the screw conveyor is vibrated and stirred, and the reinforcing agent is added and mixed, and then sent to the fabric machine through the belt conveyor.

[0032] (3) Forming: the bottom material is pressed into the desired shape by a formi...

Embodiment 2

[0036] Configure each raw material according to the following ratio:

[0037] Configure the bottom material: take 450kg of conventional cement, 1332kg of stones with a particle size of 1-3cm, and 8kg of reinforcing agent.

[0038] Configure surface materials: take 63kg white cement, 81kg black sand, 252kg white sand with a particle size of 40-80, and 0.92kg reinforcing agent.

[0039] (2) Mixing: vibrate and mix the stones required for the bottom layer materials and the cement conveyed by the screw conveyor, add the reinforcing agent and send them to the molding machine through the belt conveyor after the mixing is completed; the black sand required for the surface layer materials , White sand is mixed evenly, and the cement conveyed by the screw conveyor is vibrated and stirred, and the reinforcing agent is added and mixed, and then sent to the fabric machine through the belt conveyor.

[0040] (3) Forming: the bottom material is pressed into the desired shape by a forming m...

Embodiment 3

[0044] Configure each raw material according to the following ratio:

[0045] Configure the bottom material: take 450kg of white cement, 1332kg of stones with a particle size of 3-8cm, and 8kg of reinforcing agent.

[0046] Configure surface materials: take 63kg white cement, 81kg black sand, 252kg white sand with a particle size of 40-80, and 0.92kg reinforcing agent.

[0047] (2) Mixing: vibrate and mix the stones required for the bottom layer materials and the cement conveyed by the screw conveyor, add the reinforcing agent and send them to the molding machine through the belt conveyor after the mixing is completed; the black sand required for the surface layer materials , White sand is mixed evenly, and the cement conveyed by the screw conveyor is vibrated and stirred, and the reinforcing agent is added and mixed, and then sent to the fabric machine through the belt conveyor.

[0048] (3) Forming: the bottom material is pressed into the desired shape by a forming machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com