Preparation method of black sand primer paint assorted with ceramic tile simulated outer-wall coating

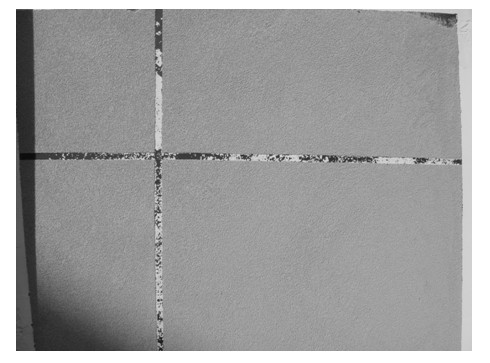

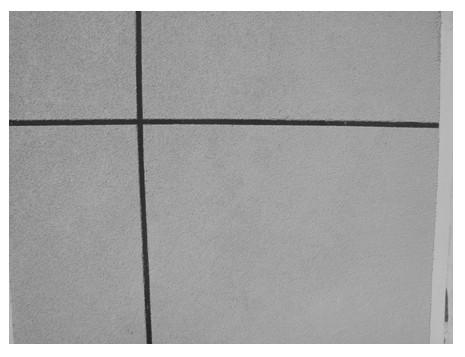

A technology of exterior wall paint and black sand, applied in the direction of coating, can solve the problems of affecting the decorative effect of the overall sand wall texture paint, uneven and dense coating surface, insufficient adhesion of black primer, etc., to achieve enhanced decorative effect, surface Uniform dense, easy thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of described coating comprises the steps:

[0027] (1) Prepare the early slurry. Add water, cellulose ether, ethylene glycol, defoamer, film-forming aid, and dispersant into the tank in sequence, and fully stir with the disperser for 20-30 minutes. Finally, add titanium dioxide and heavy calcium powder, disperse at low speed (100-300 rpm) for 3-5 minutes, then add fungicide and stir evenly.

[0028] (2) The above-mentioned slurry is introduced into the special equipment for texture paint, put into the quartz sand for dispersion, and after adding the color paste, disperse at a high speed (800-1000 rpm) for 15-20 minutes;

[0029] (3) Contrast color, inspection, warehouse loading;

[0030] Construction and Precautions

[0031] (1) Putty construction: Before scraping the texture of black sand, the wall must be dry and firm, and there should be no defects such as sanding, cracks, looseness, shelling, and hollowing (such as newly plastered cement wa...

Embodiment 1

[0034] The paint is mixed according to the following formula (parts by weight):

[0035]

[0036] The test results are as follows:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com