High-temperature-resistant polyurethane/modified vermiculite composite material and preparation method thereof

A composite material and polyurethane technology, applied in the field of high temperature resistant polyurethane/modified vermiculite composite material and its preparation, can solve the disadvantages of composite materials and other problems, and achieve simple and easy preparation method, mild reaction conditions, mechanical properties and temperature resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation method of embodiment 1 nano base vermiculite

[0016] After pulping the raw vermiculite according to the mass ratio of vermiculite to water of 1:10, add a slightly excess amount of sodium agent NaCl according to the cation exchange capacity (119mmol / 100g), stir in a water bath at 70-75°C for about 2 hours, and cool Suction filtration, washing with deionized water for several times, and then activating at 110° C. for 2 hours in an electric thermostat blast drying oven, grinding, and sieving (200 mesh) to prepare sodium-based vermiculite.

Embodiment 2

[0017] Example 2 The preparation method of different long-chain quaternary ammonium salt surfactants modified vermiculite

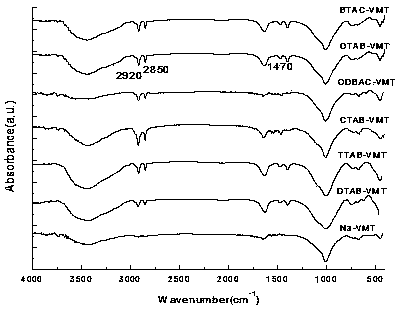

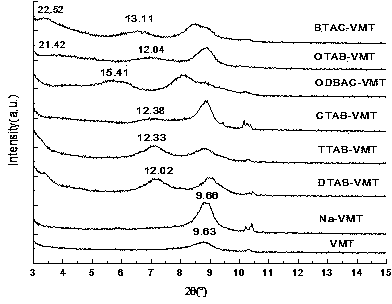

[0018] 10g nano-base vermiculite is pulped, add dodecyltrimethylammonium bromide (DTAB) 3.67g, tetradecyltrimethylammonium bromide ( TTAB) 4.00g, cetyltrimethylammonium bromide (CTAB) 4.33g, octadecyldimethylbenzyl ammonium chloride (ODBAC) 5.05g, octadecyltrimethylammonium bromide ( OTAB) 4.66g and behenyltrimethylammonium chloride (BTAC) 4.80g, stirred in a water bath at 70-75°C for about 2h, cooled and filtered, washed with deionized water several times, and then heated with an electric thermostat drum Air drying oven was activated at 110°C for 2 hours to produce different long-chain quaternary ammonium salt surfactant-modified vermiculite (X-VMT, X represents surfactant). It can be seen from the infrared spectrum that at 2920cm -1 、2850cm -1 Methyl-CH appears on both left and right 3 and methylene-CH 2 stretching vibration absorption peak; 1470cm...

Embodiment 3

[0019] Example 3 Preparation method of modified vermiculite with different additions of octadecyltrimethylammonium bromide

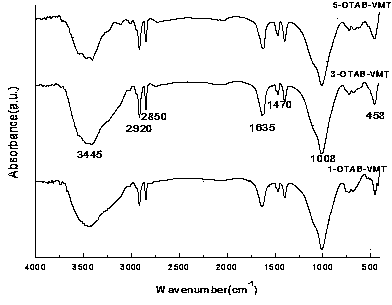

[0020] 10g nano-based vermiculite is pulped, and according to the cation exchange capacity (119mmol / 100g) of vermiculite, the addition of octadecyltrimethylammonium bromide is respectively 4.66g (1 times, 1-OTAB), 13.98g ( 3 times, 3-OTAB) and 23.30g (5 times, 5-OTAB), stirred in a water bath at 70-75°C for about 2 hours, cooled and filtered, washed with deionized water for many times, and then dried in an electric constant temperature blast drying oven Activated at 110°C for 2 hours to produce organically modified vermiculite with different additions of octadecyltrimethylammonium bromide (Y-OTAB-VMT, Y represents the multiple of OTAB). It can be seen from the infrared spectrum that 3445cm -1 The left and right broad absorption peaks are the stretching vibration absorption peaks of water-OH adsorbed on the surface and interlayer of vermiculite; 2920cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com