Waste PET-based polyurethane elastomer and preparation method thereof

A polyurethane elastomer and polyurethane elasticity technology, which is applied in the field of organic polymer resin synthesis, can solve the problems of reducing the production cost and environmental pollution of the polyurethane elastomer, and achieve the effects of reducing the production cost, being suitable for popularization and application, and having high heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

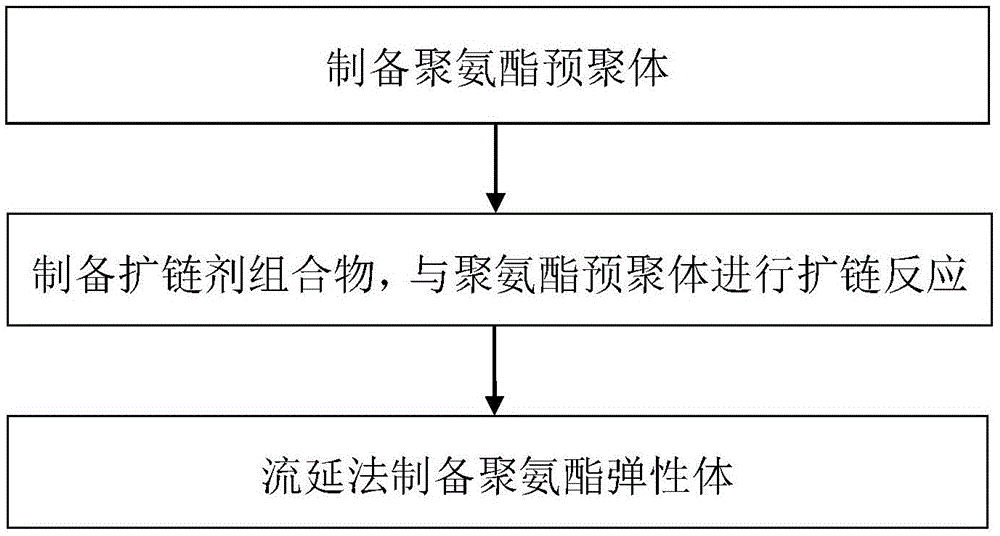

Method used

Image

Examples

Embodiment 1

[0064] Preparation of PET alcoholyzate: use waste PET bottle recycling to generate alcoholyzate, using the raw materials in parts by mass in Table 1:

[0065] Table 1 Raw material ratio table (mass percentage) of waste PET bottle recycling to generate alcoholylate

[0066] waste PET bottle

n-Butyl titanate

[0067]

NPG

(DPG)

31%

24%

40%

5%

[0068] Preparation:

[0069] a. Cut the recovered waste PET bottles into 5mm×5mm slices, place them in a beaker, pour distilled water into the beaker and stir with a glass rod, put the beaker into an ultrasonic cleaner for 20 minutes, and then clean the beaker The discarded PET flakes are poured out and filtered through an 80-mesh sieve to remove water. Repeat the above process three times, and finally put the discarded PET flakes in an 80-mesh mesh sieve to dry, and then dry them naturally in the air for 3 hours, and then ...

Embodiment 2

[0074] The present embodiment 2 prepares the polyurethane elastomer based on waste PET, adopts the raw material of mass percentage in the following table:

[0075]

[0076]

[0077] Concrete preparation process is as follows:

[0078] a. Put diphenylmethane diisocyanate (MDI), polytetrahydrofuran diol (PTMEG), polycaprolactone diol (PCL) and 1,4-cyclohexane diisocyanate (CHDI) into a stirring device , a thermometer, and a four-necked flask with a nitrogen tube, put it into an oil bath and heat up to 80°C and stir for 2 hours, add the catalyst dibutyltin dilaurate (DBTDL) and continue to stir for 30 minutes to react. During the entire reaction process, continue Nitrogen for protection;

[0079] b. Stir the mixture of N,N'-dicyclohexylcarbodiimide (DCC), neopentyl glycol (NPG) and PET alcoholylate under the action of a magnetic stirrer for 20 minutes to make it evenly mixed and have a moderate viscosity, then Quickly add the homogeneous mixture to the reaction system of ...

Embodiment 3

[0082] This Example 3 prepares a polyurethane elastomer based on waste PET. The preparation method is the same as that of Example 2, except that the ratio of raw materials is different. In this example, the following raw materials are used in mass percentages:

[0083] PTMEG

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com