Core material for vacuum heat-insulating board and preparation method thereof

A vacuum insulation panel and core material technology, which is applied in the field of vacuum insulation panel core material and its preparation, can solve the problems of reduced thermal conductivity, etc., and achieve the effects of reduced thermal conductivity, good pressure resistance stability, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

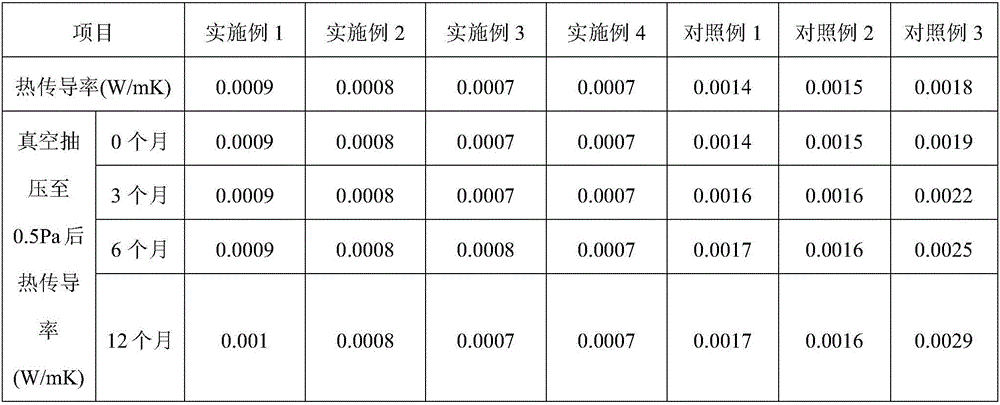

Examples

Embodiment 1

[0023] A vacuum insulation panel core material, the raw material components include: acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethylammonium chloride, stearic acid, potassium bisulfite, glass fiber, silicon dioxide , polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate glycol, 3-aminopropyltriethoxysilane, pentamethyldiethylenetriamine, bentonite, chain extender three Methylolpropane and Tween 20; the preparation method steps of the vacuum insulation board core material are as follows:

[0024] Step 1, add 5 parts of acrylic acid in parts by weight and 20 parts of water into the reaction kettle, add 2 parts of calcium oxide at room temperature, stir for 40 minutes, then add 3 parts of polyvinyl alcohol, continue stirring for 20 minutes, and heat up to 35 ℃, add 1 part of methacryloylpropyltrimethylammonium chloride, stir for 5 minutes, add 2 parts of stearic acid, 1 part of potassium bisulfite, stir and react for 200 minutes to obtain...

Embodiment 2

[0029] A vacuum insulation panel core material, the raw material components include: acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethylammonium chloride, stearic acid, potassium bisulfite, glass fiber, silicon dioxide , polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate, bis(γ-triethoxysilylpropyl) tetrasulfide, pentamethyldiethylenetriamine, Bentonite, chain extender diethylaminoethanol and Tween 20; the preparation method steps of the vacuum insulation board core material are as follows:

[0030] Step 1, add 7 parts by weight of acrylic acid and 26 parts of water into the reaction kettle, add 3 parts of calcium oxide at room temperature, stir for 43 minutes, then add 4 parts of polyvinyl alcohol, continue stirring for 25 minutes, and heat up to 36 ℃, add 1 part of methacryloylpropyltrimethylammonium chloride, stir for 7 minutes, add 3 parts of stearic acid, 2 parts of potassium bisulfite, stir and react for 230 minutes to obtain the ...

Embodiment 3

[0035] A vacuum insulation panel core material, the raw material components include: acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethylammonium chloride, stearic acid, potassium bisulfite, glass fiber, silicon dioxide , polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate glycol, 3-aminopropyltriethoxysilane, pentamethyldiethylenetriamine, bentonite, chain extender II Ethylaminoethanol and Tween 20; the preparation method steps of the core material of the vacuum insulation panel are as follows:

[0036] Step 1: Add 8 parts of acrylic acid in parts by weight and 32 parts of water into the reaction kettle, add 4 parts of calcium oxide at room temperature, stir for 48 minutes, then add 6 parts of polyvinyl alcohol, continue stirring for 25 minutes, and heat up to 38 ℃, add 2 parts of methacryloylpropyltrimethylammonium chloride, stir for 8 minutes, add 4 parts of stearic acid, 3 parts of potassium bisulfite, stir and react for 270 minutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com