Preparation method of hydroxymethylated lignin

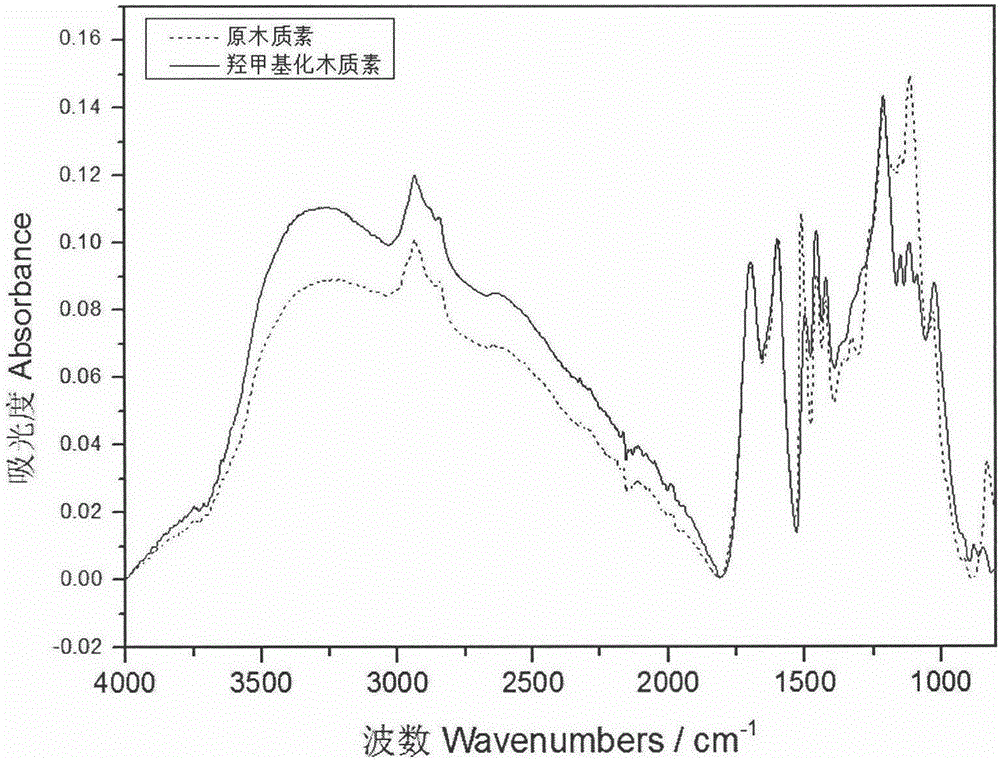

A technology for hydroxymethylation and lignin is applied in the field of microwave-assisted hydroxymethylation modified lignin preparation, and can solve the problems of low lignin activity and slow hydroxymethylation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 10g of biomass butanol lignin in 40mL of 2% NaOH solution, adjust the pH to 9 with 40% NaOH solution while stirring, add 8g of 37% formaldehyde solution and stir evenly, place the mixed solution in a microwave reactor, and React at 70°C for 15min, 30min, 45min, 60min, take samples respectively, cool to room temperature, take a small part to measure the content of free aldehyde, add acid to precipitate the rest, filter, wash and dry to obtain hydroxymethylated lignin. The amount of formaldehyde consumed measured at four times was 41.15mmol / 100gLignin, 60.06mmol / 100gLignin, 83.07mmol / 100gLignin, and 105.85mmol / 100gLignin.

Embodiment 2

[0019] Dissolve 10g of biomass butanol lignin in 40mL of 2% NaOH solution, adjust the pH to 10.5 with 40% NaOH solution while stirring, add 10g of 37% formaldehyde solution and stir evenly, put the mixed solution in a microwave reactor, React at ℃ for 15min, 30min, 45min, 60min, take samples respectively, cool to room temperature, take a small part to measure the content of free aldehyde, add acid to precipitate the rest, filter, wash and dry to obtain hydroxymethylated lignin. The amount of formaldehyde consumed measured at four times was 150.01mmol / 100gLignin, 203.54mmol / 100gLignin, 213.97mmol / 100gLignin, and 223.42mmol / 100gLignin.

Embodiment 3

[0021] Dissolve 10g of biomass butanol lignin in 40mL of 2% NaOH solution, adjust the pH to 12 with 40% NaOH solution while stirring, add 15g of 37% formaldehyde solution and stir evenly, put the mixed solution in a microwave reactor, and React at 70°C for 15min, 30min, 45min, 60min, take samples respectively, cool to room temperature, take a small part to measure the content of free aldehyde, add acid to precipitate the rest, filter, wash and dry to obtain hydroxymethylated lignin. The amount of formaldehyde consumed measured at four times was 292.20mmol / 100gLignin, 330.29mmol / 100gLignin, 347.59mmol / 100gLignin, 347.36mmol / l00gLignin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com