Preparation method and application of acid pickled ZVI (zero-valent iron) modified charcoal

A biochar and pickling technology, which is applied in the field of contaminated soil remediation, can solve the problems of affecting the reduction effect of CrCr and hindering the reduction reaction, so as to increase the surface activity site of the target product, facilitate the reduction, and increase the content of carboxyl and hydroxyl groups Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

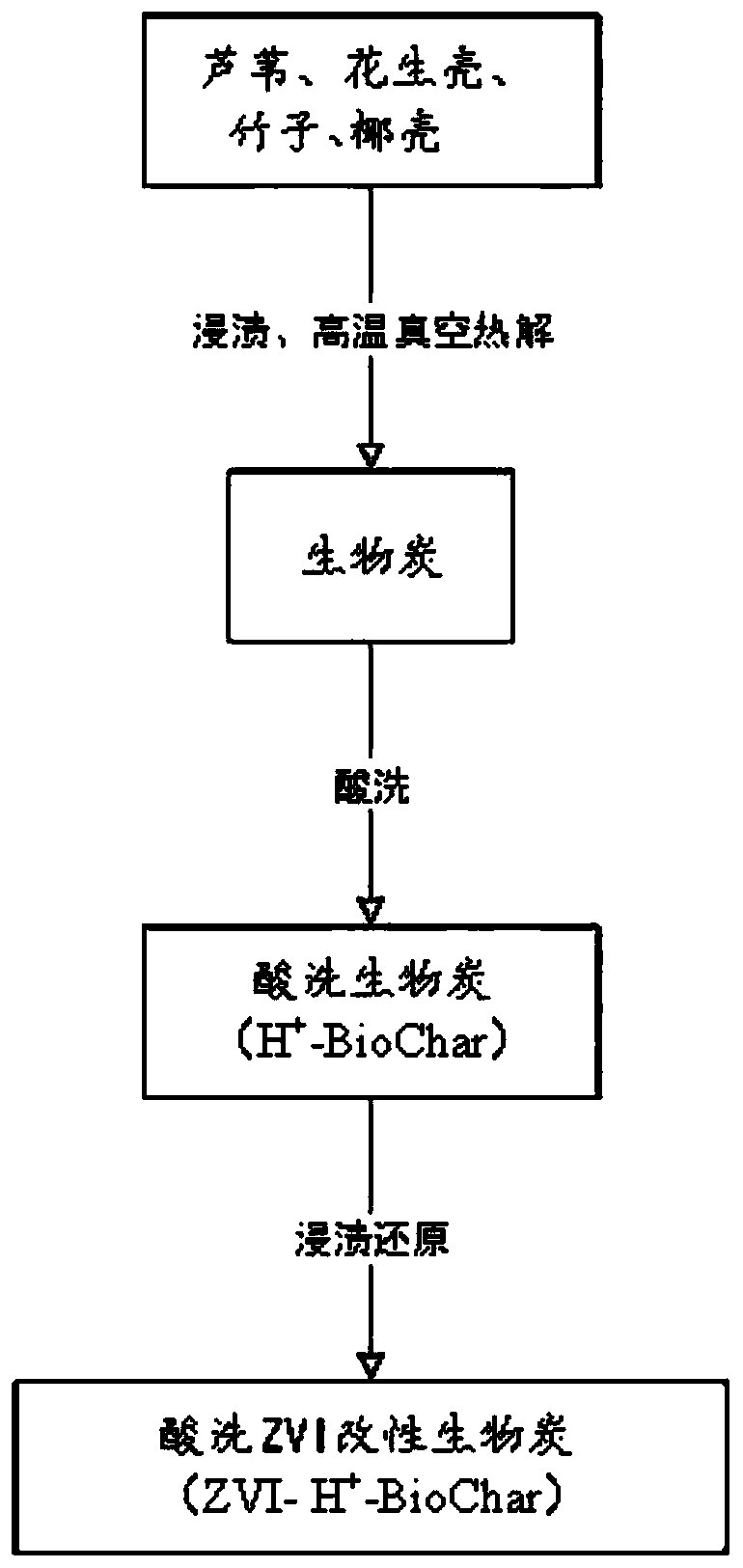

[0031] Such as figure 1 As shown, this embodiment provides a method for preparing acid-washed ZVI modified biochar, and the specific process is as follows:

[0032] (1) Crush and grind the two biomass raw materials (mass ratio 1:1) of reeds and peanut shells, pass through a 60-mesh standard sieve, and dry in a cool place to remove non-wood impurities in them, and then place them at 105°C Dry to constant weight in a constant temperature drying box, set aside.

[0033] (2) Take the above-mentioned dry biomass raw material into the reaction kettle, add the prepared 20% glucose solution for soaking, soak for 24h, the mass ratio of the above-mentioned soaked biomass to the soaking solution is 1:5, centrifuge for dehydration, and then put it in 105 Dried to constant weight in a constant temperature drying oven at ℃, ready for use.

[0034] (3) The above-mentioned soaked biomass is pyrolyzed in a vacuum box-type atmosphere furnace at 600°C under nitrogen protection for 4 hours, cooled to r...

Embodiment 2

[0038] Such as figure 1 As shown, this embodiment provides a method for preparing acid-washed ZVI modified biochar, and the specific process is as follows:

[0039] (1) The bamboo, a biomass raw material, is crushed and ground, passed through a 30-mesh standard sieve, and dried in a cool place to remove the non-wood impurities, and then placed in a constant temperature drying oven at 105°C to dry to constant weight. use.

[0040] (2) Take the above-mentioned dry biomass raw material into the reactor, add the prepared 15% ferric sulfate solution to soak, soak for 24h, the mass ratio of the above-mentioned soaked biomass to the soaking solution is 1:4, centrifuge for dehydration, and place Dried to constant weight in a constant temperature drying oven at 105°C for use.

[0041] (3) The above-mentioned soaked biomass is pyrolyzed in a vacuum box atmosphere furnace at 500° C. under nitrogen protection for 5 hours, cooled to room temperature, ground, and passed through a 100-mesh standar...

Embodiment 3

[0045] Such as figure 1 As shown, this embodiment provides a method for preparing acid-washed ZVI modified biochar, and the specific process is as follows:

[0046] (1) Crush and grind four kinds of biomass raw materials (mass ratio 3:3:3:1) of reed, peanut shell, bamboo and coconut shell, pass a 20-mesh standard sieve, and place in a cool place to dry, and remove any non-toxic substances. Wood impurities are then placed in a constant temperature drying oven at 105°C to be dried to a constant weight, ready for use.

[0047] (2) Take the above-mentioned dry biomass raw material into the reactor, add the prepared 15% ferric sulfate solution to soak, soak for 24h, the mass ratio of the above-mentioned soaked biomass to the soaking solution is 1:5, centrifuge for dehydration, and then place Dried to constant weight in a constant temperature drying oven at 105°C for use.

[0048] (3) The above-mentioned soaked biomass is pyrolyzed in a vacuum box atmosphere furnace at 550°C under nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com