Fine-grain material centrifugal filtering and dewatering device

A technology of centrifugal filtration and dehydration device, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of high power consumption, high maintenance costs, high maintenance costs, etc., and achieve low equipment energy consumption and maintenance costs. Less and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

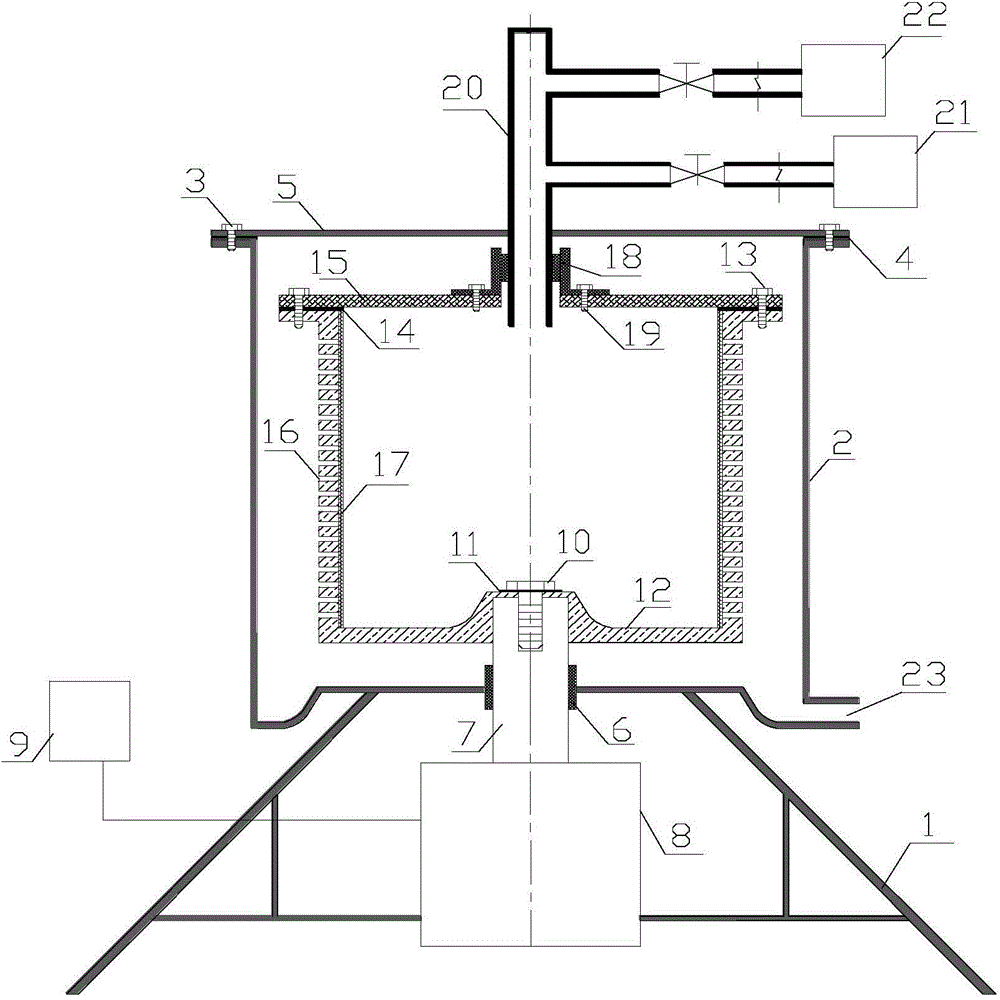

[0025] The centrifugal filtration and dehydration device for fine material of the present invention mainly consists of a frame 1, a casing 2, a rotating drum 12, a motor 8 and a governor 9. The casing 2 is set on the top of the frame 1, the motor 8 is set on the bottom of the frame 1, the casing 2 is provided with a drum 12, the motor 8 is connected with a governor 9, and the main shaft 7 of the motor 8 passes through the casing 2. The bottom is connected with the rotating drum 12, the main shaft 7 passes through the casing 2 and a sealing assembly 6 is provided; the upper part of the casing 2 is provided with a casing upper cover 5, and the lower part is provided with a liquid discharge port 23, and the casing upper cover 5 Connect with the casing 2 through the bolt 3 and the sealing ring 4. There are several filtrate holes 16 on the side wall of the drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com