Autotrophic denitrification synchronous sludge fermentation coupled denitrification device and method for sewage with low nitrogen ratio

An autotrophic denitrification and denitrification technology, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problem of lack of effective control of the proportional relationship, and achieve reduction treatment and utilization, and improve Effects of treatment efficiency, treatment cost savings and floor space savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

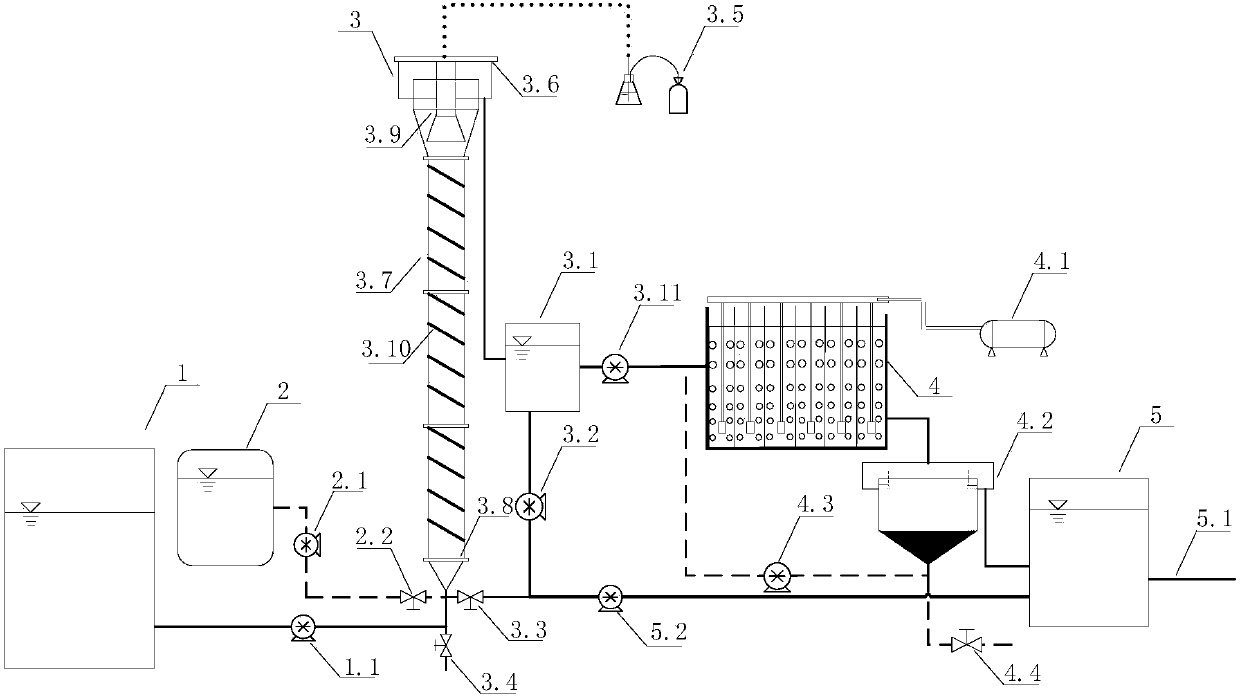

[0031] Such as figure 1As shown, the low carbon nitrogen ratio sewage autotrophic denitrification synchronous sludge fermentation coupled denitrification device is equipped with a raw water tank 1, a sludge storage tank 2, an autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor 3, and a short-range nitrification reactor 4. Drainage pool 5; the raw water tank 1 is connected to the bottom of the autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor 3 through the inlet pump 1.1, and the autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor 3 is passed through the outlet pump 3.11 It is connected with the 4 first chambers of the short-range nitrification reactor; the short-range nitrification reactor 4 is divided into 4-9 compartments with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com