High-temperature anaerobic fermentation process for breeding wastewater

A high-temperature anaerobic fermentation and breeding wastewater technology, which is applied in aerobic and anaerobic process treatment, anaerobic digestion treatment, animal husbandry wastewater treatment, etc., to achieve the effects of accelerating release, preventing accumulation, and shortening start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The aquaculture wastewater indicators used in this example are OLR=3.125, TS=5.208g·L -1 .

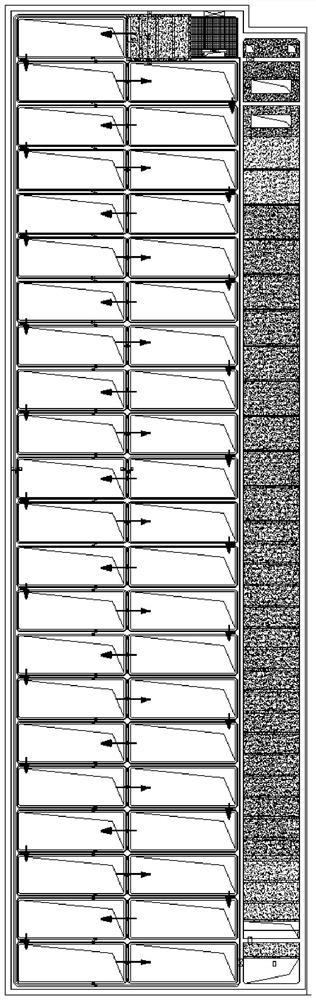

[0024] First, the collected aquaculture wastewater is pretreated, and the wastewater is pumped into the aeration adjustment tank through the water collection well, and the aquaculture wastewater is acidified and hydrolyzed. The hydraulic retention time is 4.5h. At the same time, a submersible mixer is installed in the aeration tank, which can maintain the The movement of the middle water flow improves the hydrolysis efficiency and prevents the sludge deposition from affecting the subsequent use of the aeration tank; then the wastewater is passed into the 22-grid baffled anaerobic reaction tank with a length of 31 meters, and the wastewater is added to the gas-liquid heating mixer with steam. It is heated to 55°C for anaerobic fermentation, and the wastewater flows in the anaerobic reaction tank through baffles during fermentation to ensure the residence reaction time of the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com