Kitchen waste treatment method and equipment

A technology of kitchen waste and treatment equipment, which is applied in the field of low-energy kitchen waste treatment methods and equipment, can solve the problems of low calorific value of organic waste, unstable incineration, unfavorable flue gas treatment, etc., to achieve less waste gas generation, Solve governance problems and achieve a high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

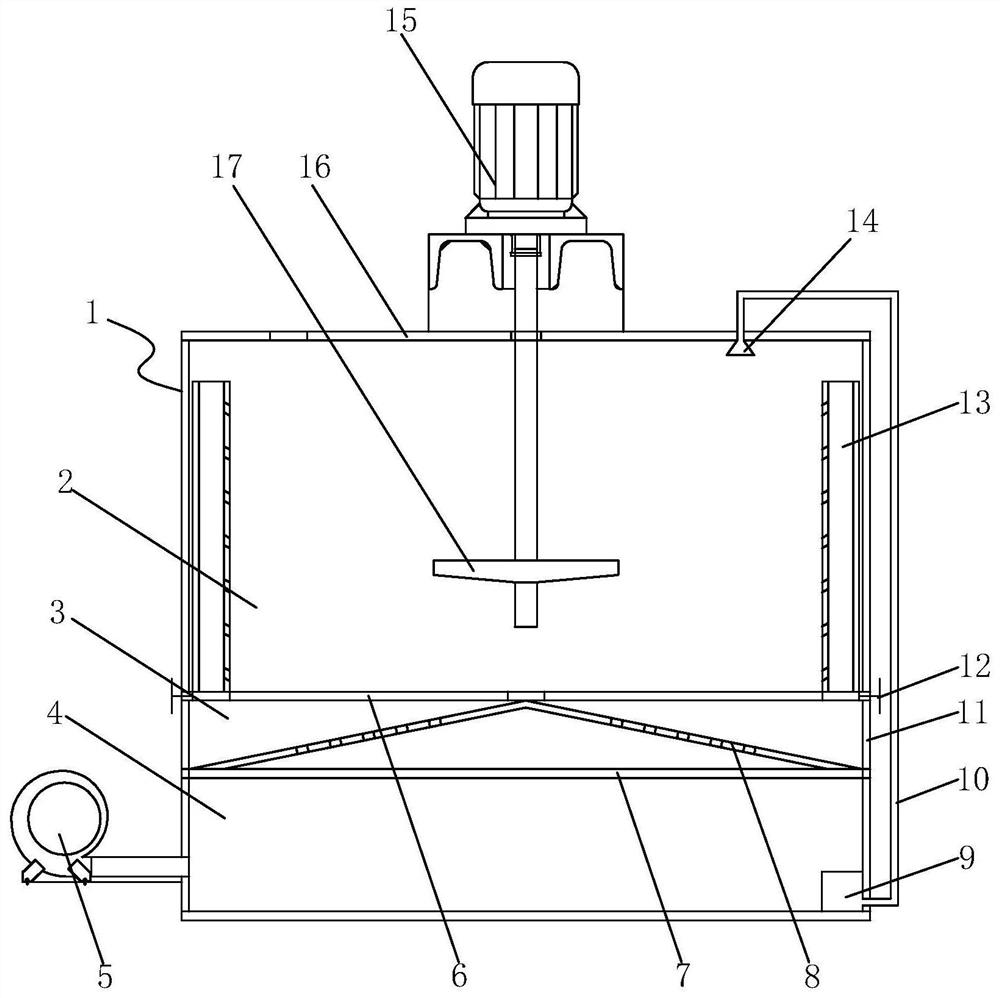

[0024] A kind of kitchen waste processing method of the present invention, comprises the following steps:

[0025] S1. Crushing: Put the kitchen waste into the pulverizer for pulverization;

[0026] S2. Preparation with additional waste: put in water-removing additives, adjust the water content of the pulverized kitchen waste to 40%~60%; in this embodiment, the water-removing additives are wheat bran, straw, sawdust or dried livestock and poultry. Any one or a mixture of feces;

[0027] S3. Aerobic fermentation: Slowly put the kitchen waste obtained in step S2 into the reaction chamber of the kitchen waste treatment equipment, and put in the fermentation bacteria. At the same time, the temperature is controlled at 55 ° C ~ 65 ° C, and natural ventilation and blower air supply are adopted. Combined form, so that kitchen waste is fermented in the reaction chamber;

[0028] S4. Microbial deodorization: After the kitchen waste is fermented and matured, deodorizing microbial stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com