Method for noise comprehensive treatment of cement plant

A comprehensive treatment and cement plant technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of too many sound source equipment and no reasonable plan for comprehensive treatment of noise at the cement plant boundary, and achieve the effect of solving the problem of treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

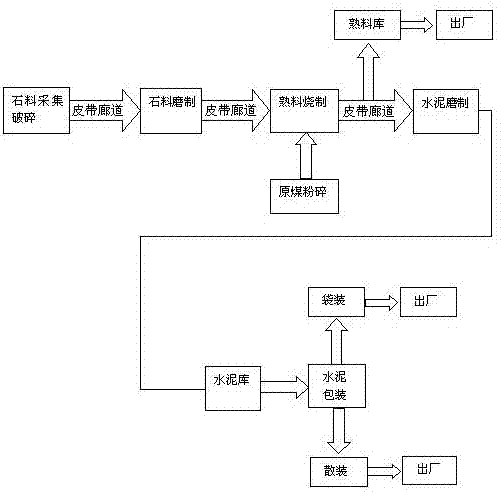

Image

Examples

Embodiment Construction

[0032] Regarding the reasons for the existing problems in the prior art, the inventor found in the process of research and development that many people think that noise control is very simple, just building walls or making some sound insulation barriers, but noise control in cement plants Among them, through the treatment of the existing technology, in many cases, the effect of noise reduction is obvious, but it still cannot reach the standard, and it is only a few decibels away from the standard value. How to really reach the standard, the existing technology cannot answer.

[0033] For example: According to the standard of Class 2, it is less than or equal to 50dB at night, but most cement plants use electricity at staggered peaks and produce at night. If they want to drop from 55dB to less than 50dB, the cost will be more than the sum of all the previous treatment costs. Therefore, there is a big difference between "reducing a little" and "reducing to the standard". The nois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com