Acid-soluble soybean protein and preparation method and application of acid-soluble soybean protein in acid beverage

A soybean protein and acidic beverage technology, applied in soybean protein and its application in functional beverages, soybean protein deep processing and its application fields, can solve the problems of limited product solubility and the inability of membrane separators to realize industrialized large-scale production, etc. Achieve the effects of reducing the content of phytic acid, good foaming performance and small degree of denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

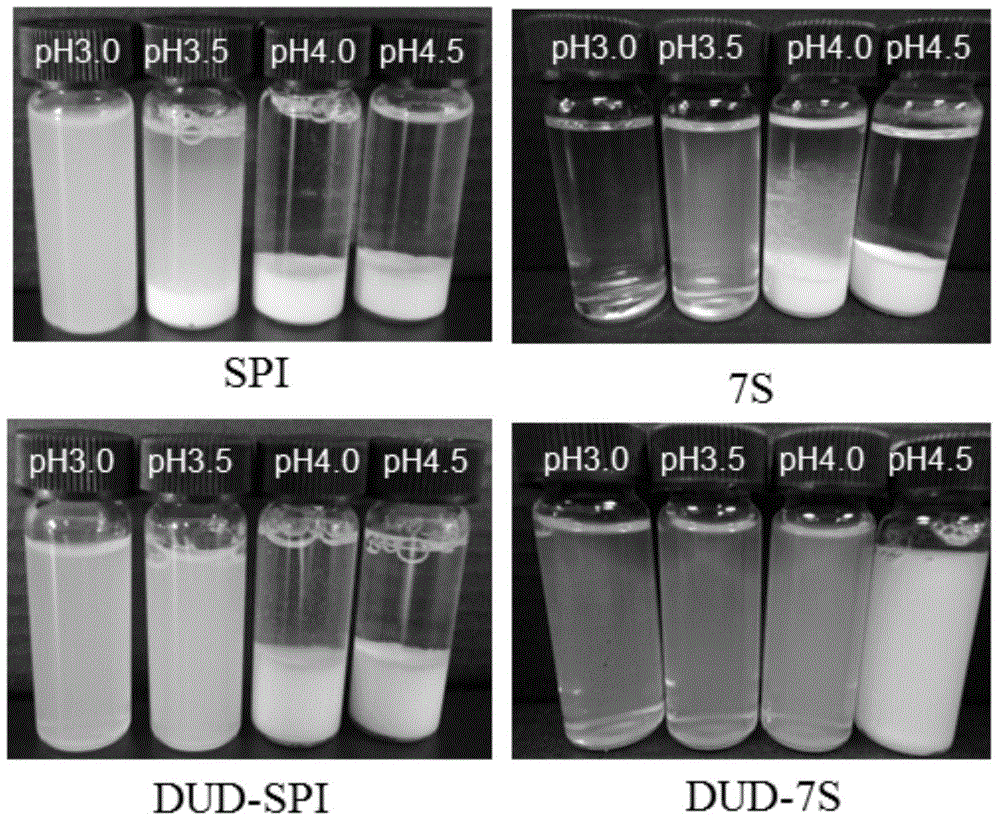

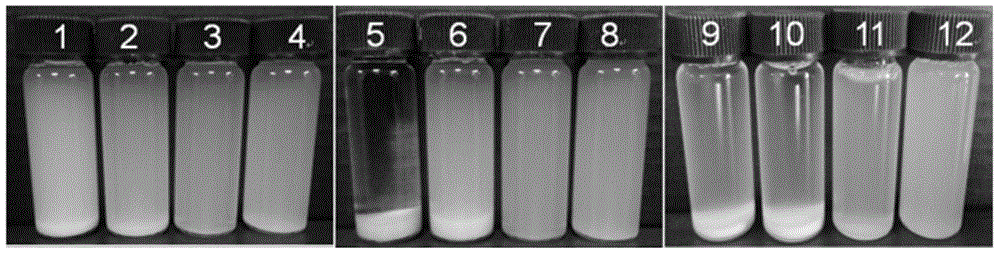

[0035] (1) Mix 1,000 mL of 0.1 mol / L NaCl extract with 100 g of 7S-rich defatted soybean meal, stir at room temperature for 30 min, centrifuge at 3,000 rpm for 15 min at 25°C, filter with 400-mesh gauze at room temperature and pressure, and discard the precipitate , take the supernatant and measure its volume, add NaHSO 3 , so that the concentration in the supernatant is 1.5g / L, let it stand for 20min, and adjust the pH to 5.0;

[0036] (2) Add phytase to the above clear liquid, carry out enzymatic hydrolysis at 50°C for 25 minutes, add 1 times the volume of distilled water to the solution after enzymatic hydrolysis, and adjust the pH to 4.0;

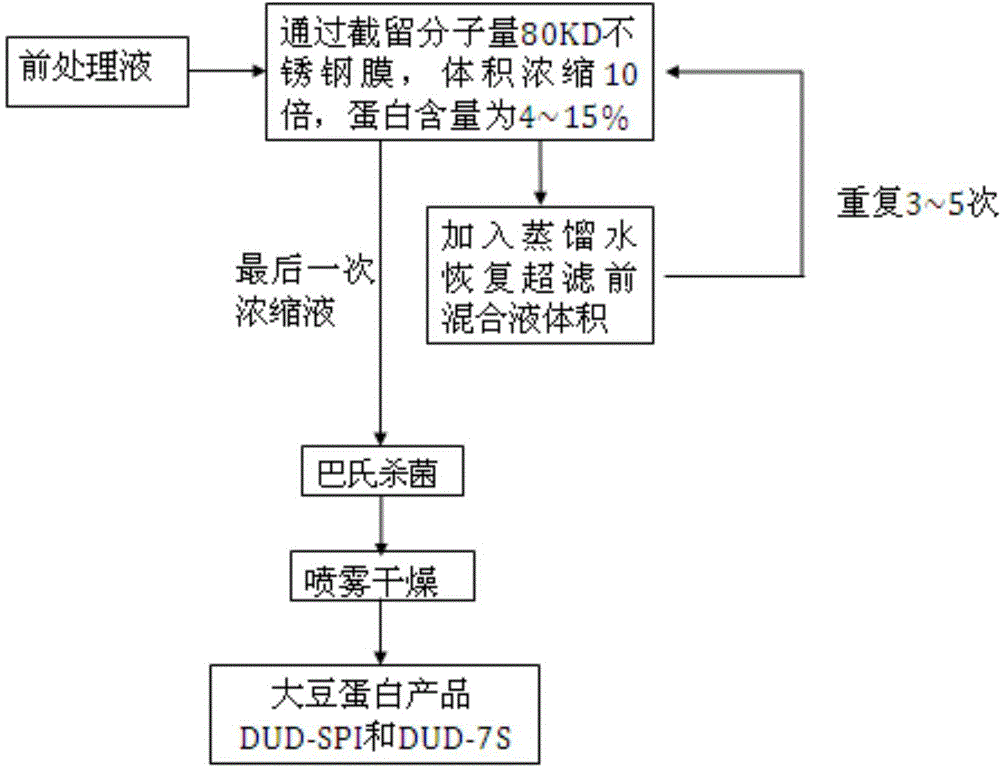

[0037] (3) Concentrate the solution obtained in step (2) by circulating ultrafiltration and diafiltration under the condition of a water bath at 30°C. After the volume is concentrated to 1 / 8 of the original volume, add distilled water to restore it to the original volume, and repeat the ultrafiltration and diafiltration 5 times, no nee...

Embodiment 2

[0045] (1) Mix 1,500 mL of 0.1 mol / L KCl extract with 100 g of 7S-rich defatted soybean meal, stir at room temperature for 60 min, centrifuge at 8,000 rpm for 20 min at 25°C, filter with 200-mesh gauze at room temperature and pressure, and discard the precipitate , take the supernatant and measure its volume, add NaHSO 3 , so that the concentration in the supernatant is 0.8g / L, let it stand for 10min, and adjust the pH to 4.0;

[0046] (2) Add phytase to the above clear liquid, carry out enzymatic hydrolysis at 30°C for 40 minutes, add 2 times the volume of distilled water to the solution after the enzymatic hydrolysis, and adjust the pH to 3.0;

[0047] (3) Concentrate the solution obtained in step (2) by circulating ultrafiltration and diafiltration under the condition of a water bath at 50°C. After the volume is concentrated to 1 / 12 of the original volume, add distilled water to restore it to the original volume, and repeat the ultrafiltration and diafiltration 3 times, no...

Embodiment 3

[0052] (1) 1500mL of 0.1mol / L MgCl 2 Mix the extract with 100g of 7S-rich defatted soybean meal, stir at room temperature for 35min, centrifuge at 25°C at 3000rpm for 20min, filter with 200-mesh gauze at normal temperature and pressure, discard the precipitate, take the supernatant and measure its volume, add NaHSO 3 , so that the concentration in the supernatant is 1g / L, let it stand for 30min, and adjust the pH to 4.0;

[0053] (2) Add phytase to the above clear liquid, carry out enzymatic hydrolysis at 30°C for 30 minutes, add 2 times the volume of distilled water to the solution after the enzymatic hydrolysis, and adjust the pH to 3.0;

[0054] (3) Concentrate the solution obtained in step (2) by circulating ultrafiltration and diafiltration under the condition of a water bath at 40°C. After the volume is concentrated to 1 / 12 of the original volume, add distilled water to restore it to the original volume, and repeat the ultrafiltration and diafiltration 3 times, no need ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com