Method for preparing magnesium hydrate flame retardant

A magnesium hydroxide and flame retardant technology, which is applied in dyeing organosilicon compound treatment, dyeing low molecular organic compound treatment, dyeing physical treatment, etc., can solve the problems of difficult product performance guarantee, complicated process flow, and many influencing factors. Achieve the effects of improving production efficiency, shortening the process flow, and increasing the filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

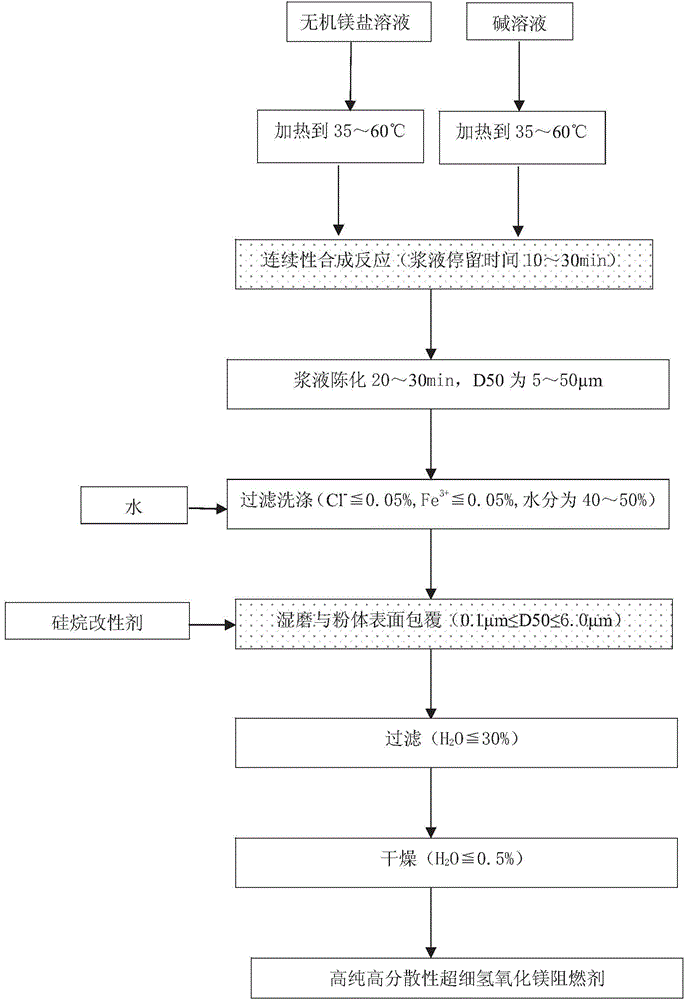

[0024] The preparation method of magnesium hydroxide flame retardant of the present invention comprises the following steps, combining figure 1 Shown:

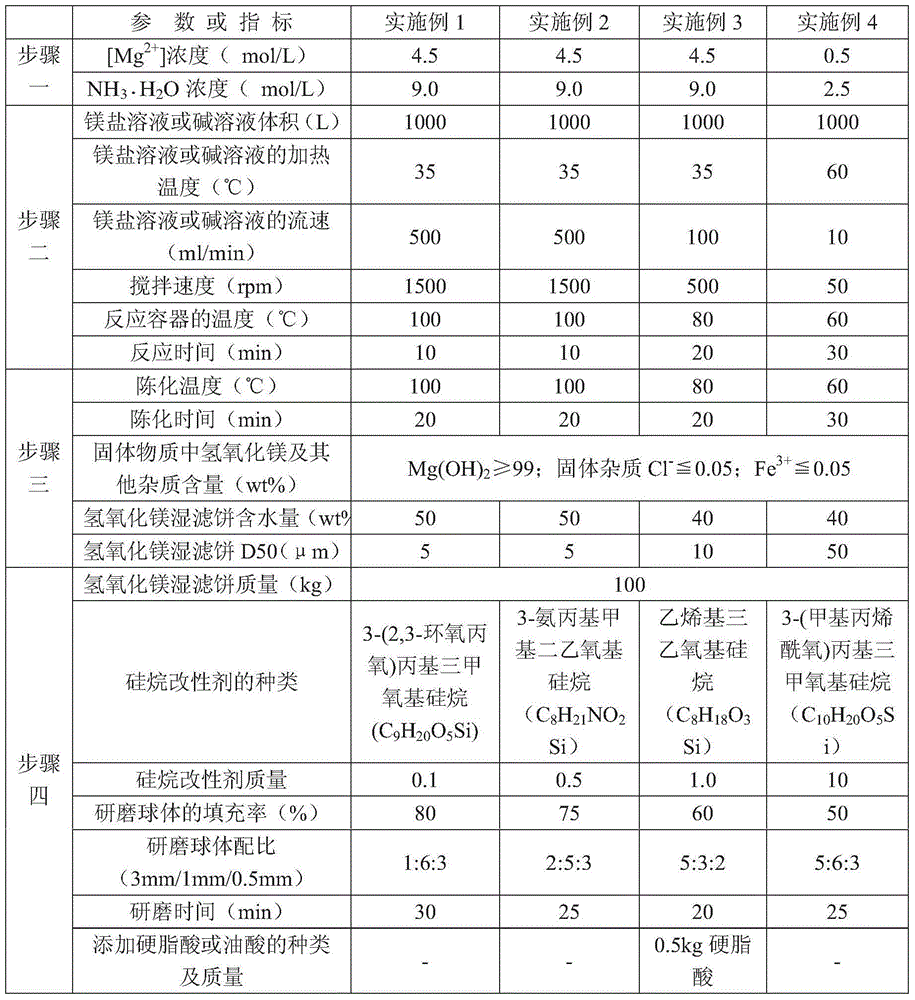

[0025] Step 1, preparing inorganic magnesium salt solution and alkali solution respectively.

[0026] Among them, water-soluble salts such as magnesium chloride, magnesium sulfate, and magnesium nitrate can be used as the inorganic magnesium salt. Formulated Mg 2+ The concentration range of the substance is 0.5~5mol / L.

[0027] The alkali solution that the present invention adopts is ammoniacal liquor, controls OH - The concentration range of the substance is 0.02~10mol / L. Certainly, adopting other common inorganic alkalis such as sodium hydroxide, potassium hydroxide etc. also can achieve the object of the present invention, but need to strictly control the flow rate and the concentration of adding alkali. Ammonia and Mg 2+ Formed Mg(OH) 2 The precipitated particles are not too fine, and the obtained magnesium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com