Multipurpose tray

A pallet and support board technology, applied in rigid containers, containers, packaging, etc., can solve the problems of broken brackets, inability to use universally, single-transport flat-bottomed items or roll-shaped items, etc., and achieve the effect of increasing the diversification of use and enhancing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

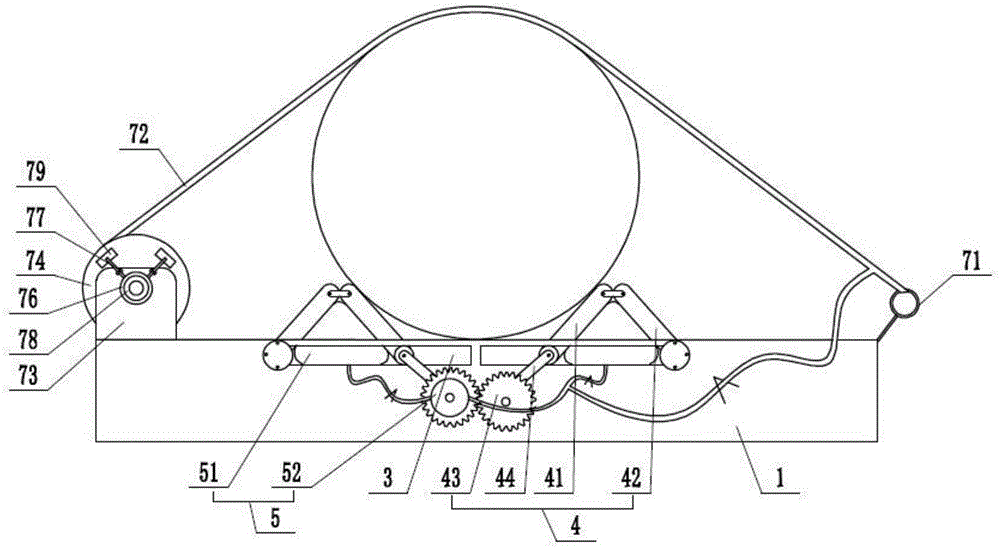

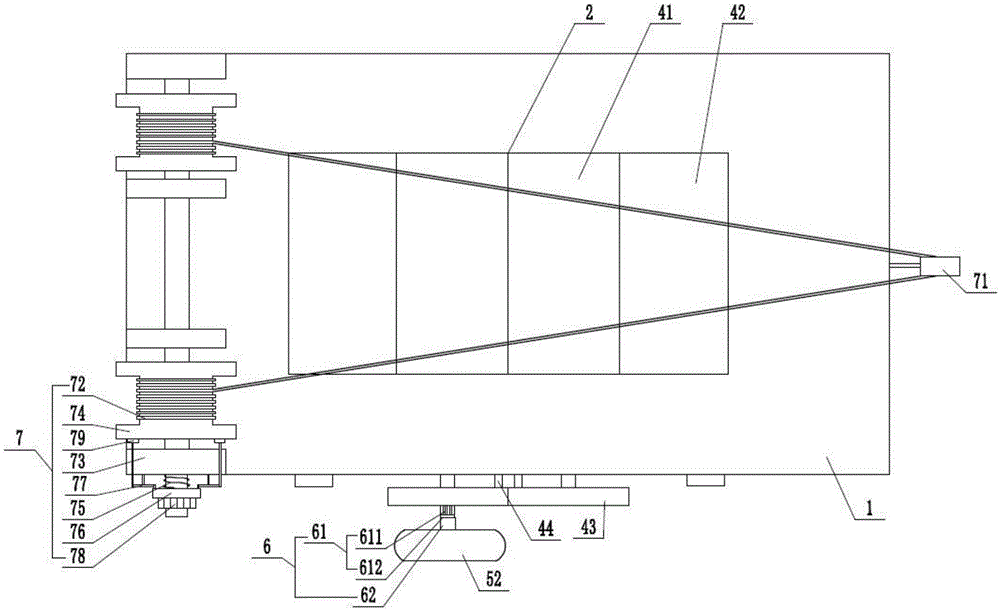

[0015] refer to Figure 1 ~ Figure 2 Shown: a multi-purpose tray, including a square support plate 1, a groove 2 is opened on the top of the support plate 1, and a chute 3 communicating with the groove 2 is opened on both sides of the support plate 1 opposite to each other. 2 is provided with two symmetrically arranged and identically structured adjustable support frames 4 that are rotationally connected in the chute 3, and the adjustable support frames 4 are all provided with auxiliary support mechanisms 5, and the support plate 1 is provided with a Binding device7.

[0016] The adjustable support frame 4 includes an active plate 41 slidably and rotatably connected in the chute 3 , a driven plate 42 rotatably connected in the chute 3 , and a rotatably connected side of the support plate 1 with the chute 3 . The gear 43 on the wall is hingedly connected between the active plate 41 and the driven plate 42, the eccentric position of the gear 43 is hinged with a connecting rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com