Novel multifunctional numerical control 3D printing equipment and using method

A 3D printing, multi-functional technology, applied in the field of new multi-functional CNC 3D printing equipment, can solve the problems of inconvenient processing, insufficient flexibility in the selection of raw materials, and high cost investment, and achieve the effect of reducing the purchase cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment, further illustrate the present invention.

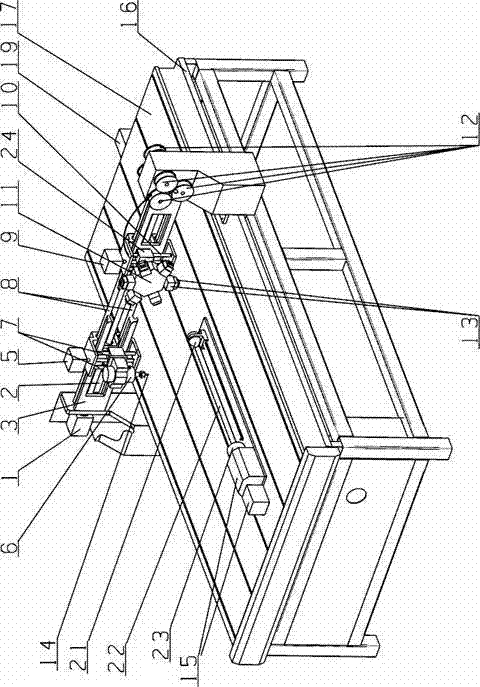

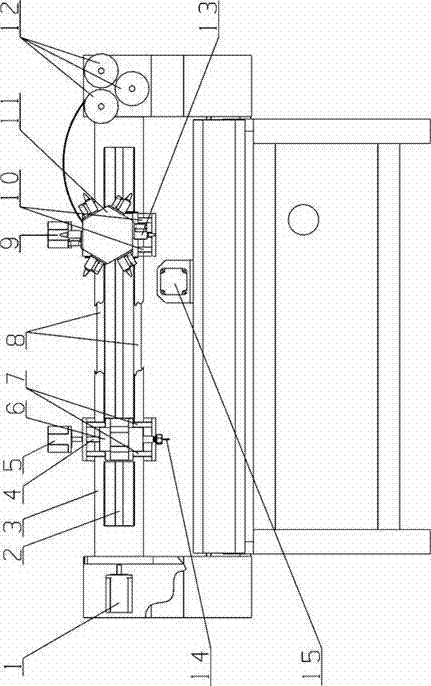

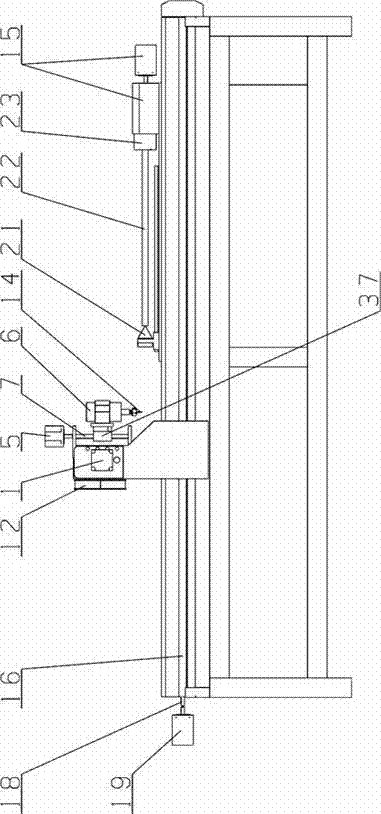

[0029] see Figure 1-Figure 7 , the present invention comprises workbench 17, and described workbench 17 is provided with gantry 3, and described gantry is suspended with processing cutter 14 through suspension drive mechanism 1, and described gantry 3 is suspended with 3D printing head through suspension drive mechanism 2 .

[0030] A work chuck is also arranged on the workbench 17 .

[0031] Described suspension driving mechanism one comprises support seat one 35, and described support seat one 35 upper ends are provided with cutting head Z-axis stepping motor 5, and described cutting head Z-axis stepping motor 5 is connected cutting head Z-axis lead screw 4, so The Z-axis guide rail 7 of the cutting head is also arranged in the support seat one 35, the Z-axis guide rail 7 of the cutting head is connected with the slider 37 of the cutting head on the Z-axis screw 4 of the cutting head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com