Bearing test device capable of loading alternating load

A technology of alternating load and bearing test, applied in the direction of mechanical bearing test, etc., can solve the problems of inability to realize variable load loading, single loading characteristic, and difficult to carry out dynamic load bearing test of engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

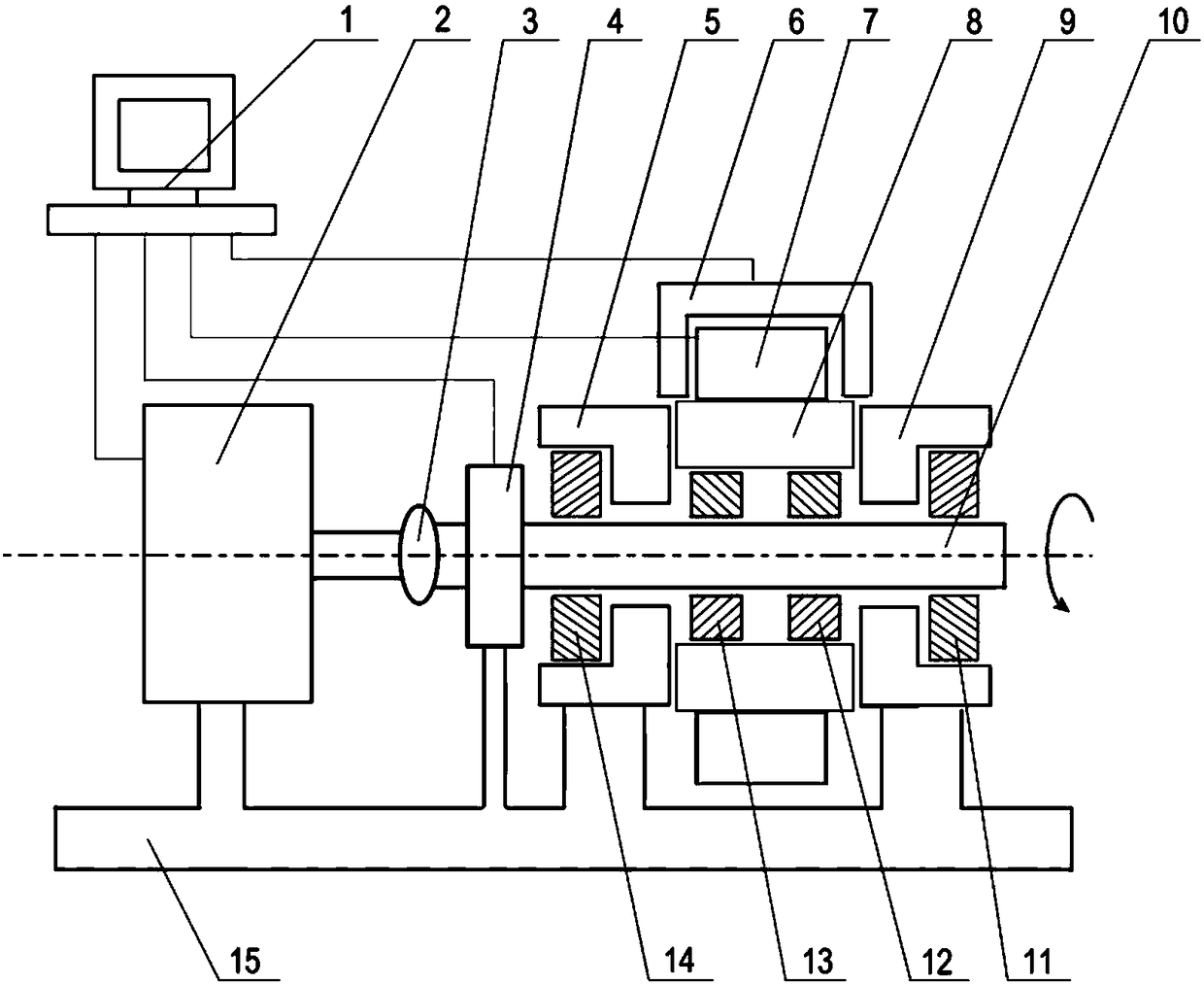

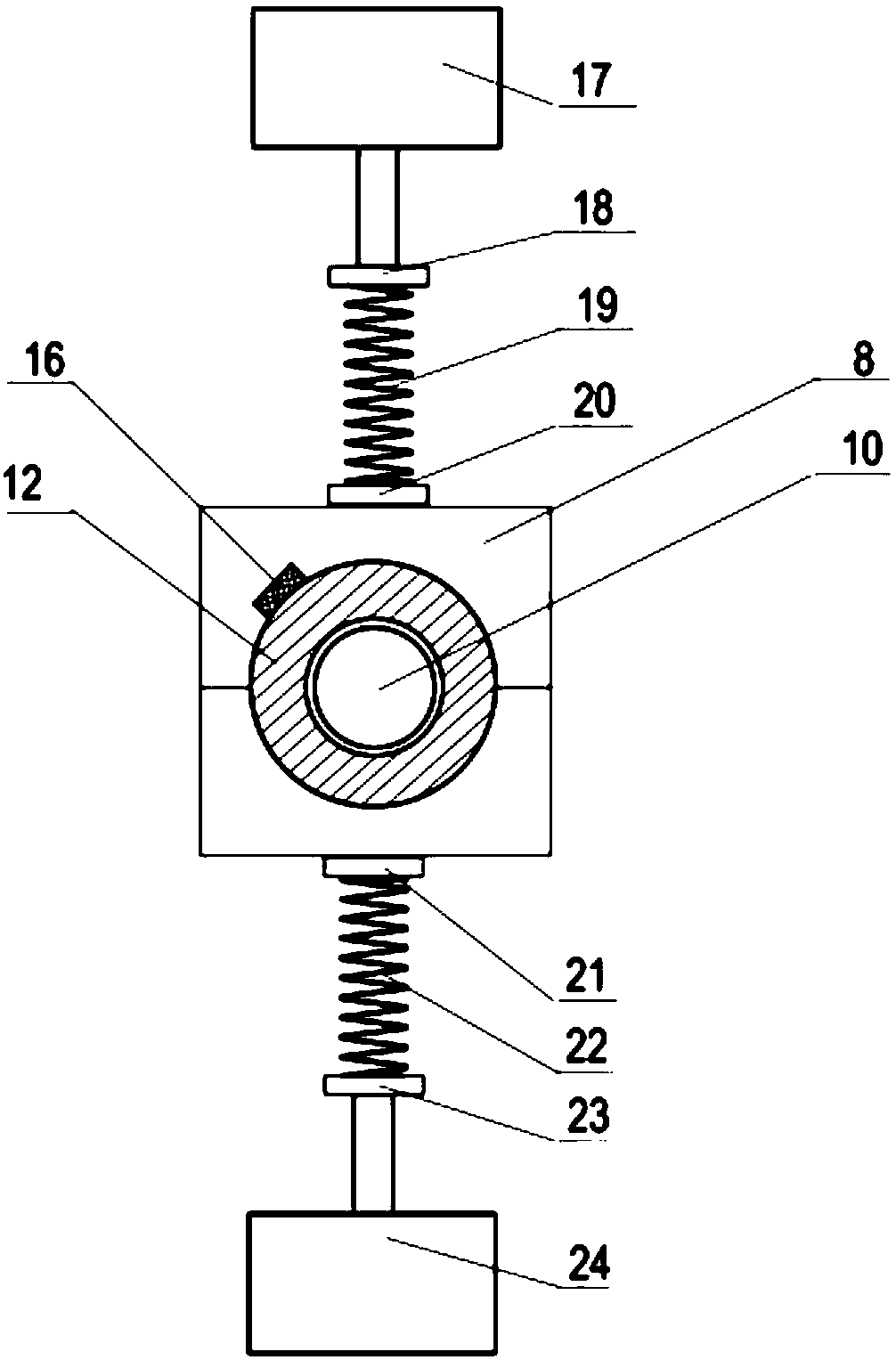

[0027] A bearing test device that can be loaded with alternating loads, such as figure 1 As shown, the device includes a computer 1, a rotating motor 2, a coupling 3, a torque meter 4, a fixed fixture A 5, an oil supply system 6, an alternating load loading module 7, a movable fixture 8, a fixed fixture B9, and a rotating shaft 10 , the accompanying test sliding bearing B 11, the tested sliding bearing B 12, the tested sliding bearing A 13, the accompanying test sliding bearing A14, and the working platform 15. Among them, such as figure 2 As shown, the alternating load loading module 7 includes a temperature sensor 16, a linear motor A 17, a connecting device Aa 18, a spring A 19, a connecting device Ab 20, a connecting device Bb 21, a spring B 22, a connecting device Ba 23, and a linear motor B twenty four.

[0028] Wherein, the rotating motor 2 , the torque meter 4 , the fixing fixture A 5 and the fixing fixture B 9 are installed on the workbench 15 . The rotating motor...

Embodiment 2

[0032] A bearing test device capable of loading alternating loads, its structure is roughly the same as that of Embodiment 1, the difference is that a protective sleeve is also set on the output shaft of the linear motor in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com