A steel wire stay

A rope fixation and steel wire rope technology, which is applied in the direction of transmission elements or pulley ropes or cables, belts/chains/gears, mechanical equipment, etc., can solve the problem that there is no elastic component in the steel wire rope fixing seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

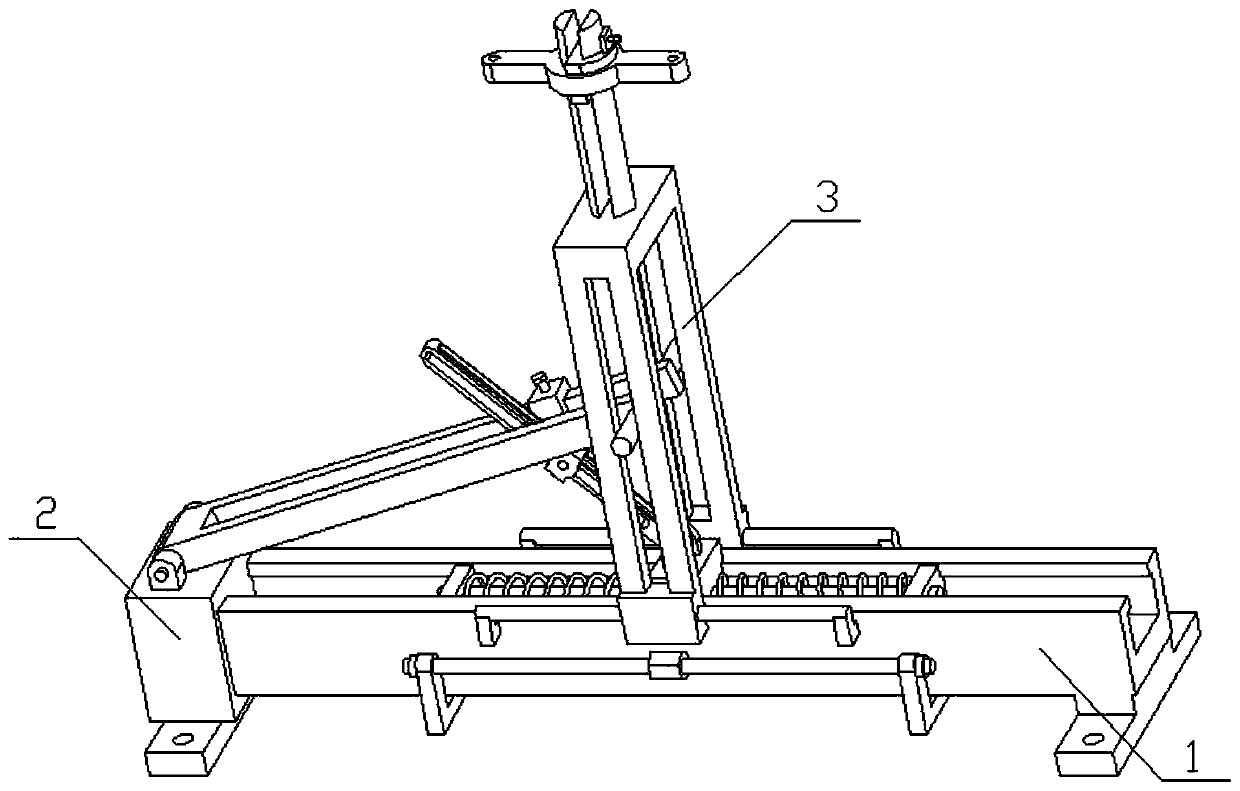

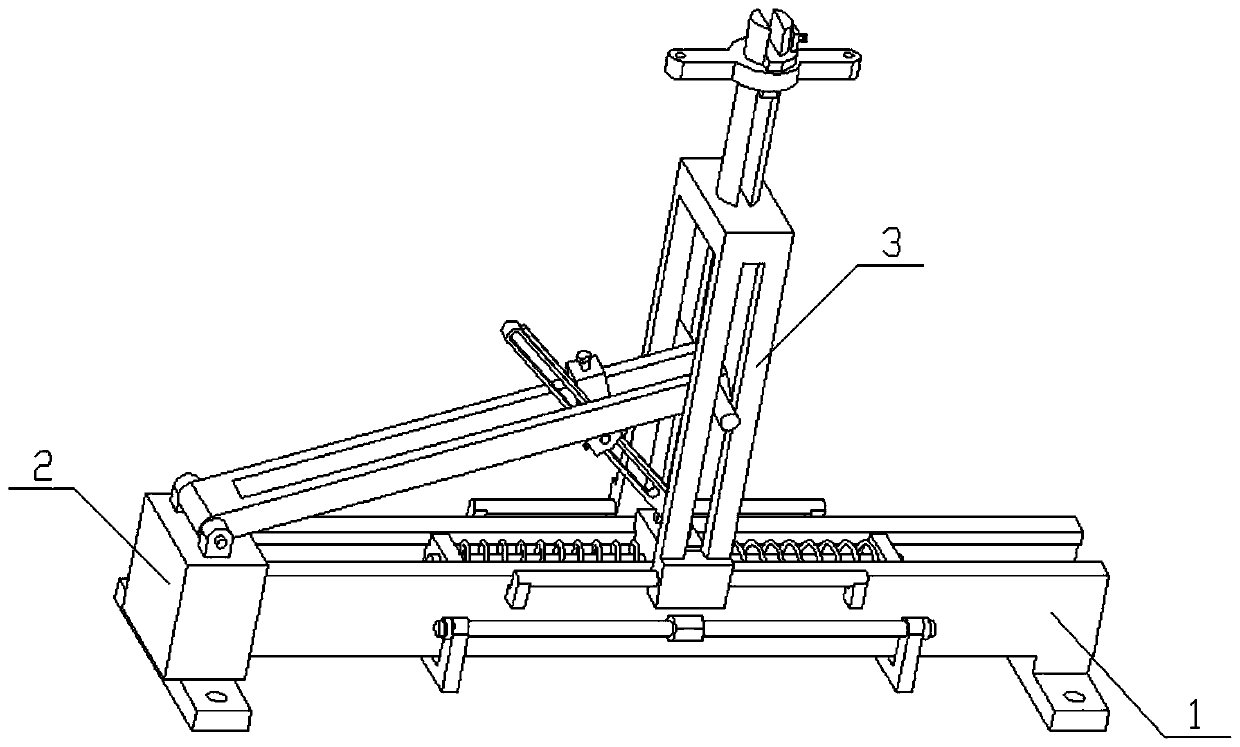

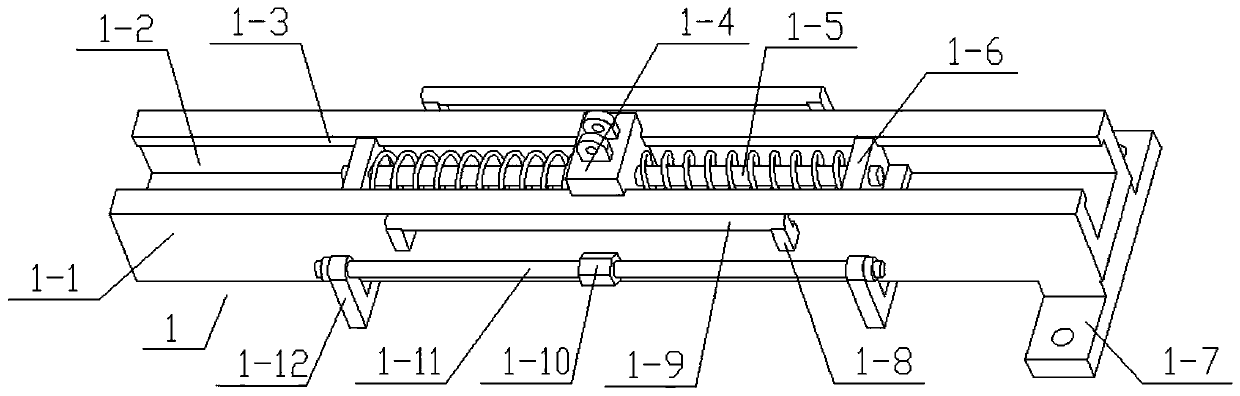

[0026] Combine below Figure 1-10 To illustrate this embodiment, the present invention relates to a fixed seat, more specifically, a steel wire stay rope fixed seat, which includes an elastic seat body 1, a force transmission component 2 and a wire rope connector 3, and one end of the steel wire stay rope can be tied to the On the device, and the left and right ends of the device can be tied into the steel wire rope, and the steel wire rope can still be pulled a small distance after straightening, which is convenient to adapt to the specific situation of the steel wire rope in actual use; and the tension of the steel wire rope is fixed. , when the pulling force is transmitted to the spring, the magnitude of the spring force can be adjusted as required, thereby controlling the magnitude of the elastic force given by the device to the steel wire stay rope.

[0027] The elastic seat body 1 includes a seat post 1-1, a seat post inner groove 1-2, a rib 1-3, a middle slider 1-4, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com