Rolling bearing fatigue life testing system for loading radial alternating load by lead screw drive

A rolling bearing and alternating load technology, applied in the field of engine rolling bearing life test, can solve the problems of unable to achieve variable load, single loading characteristics, difficult to develop engine dynamic load rolling bearing fatigue life, etc., to achieve high accuracy and improve accuracy , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

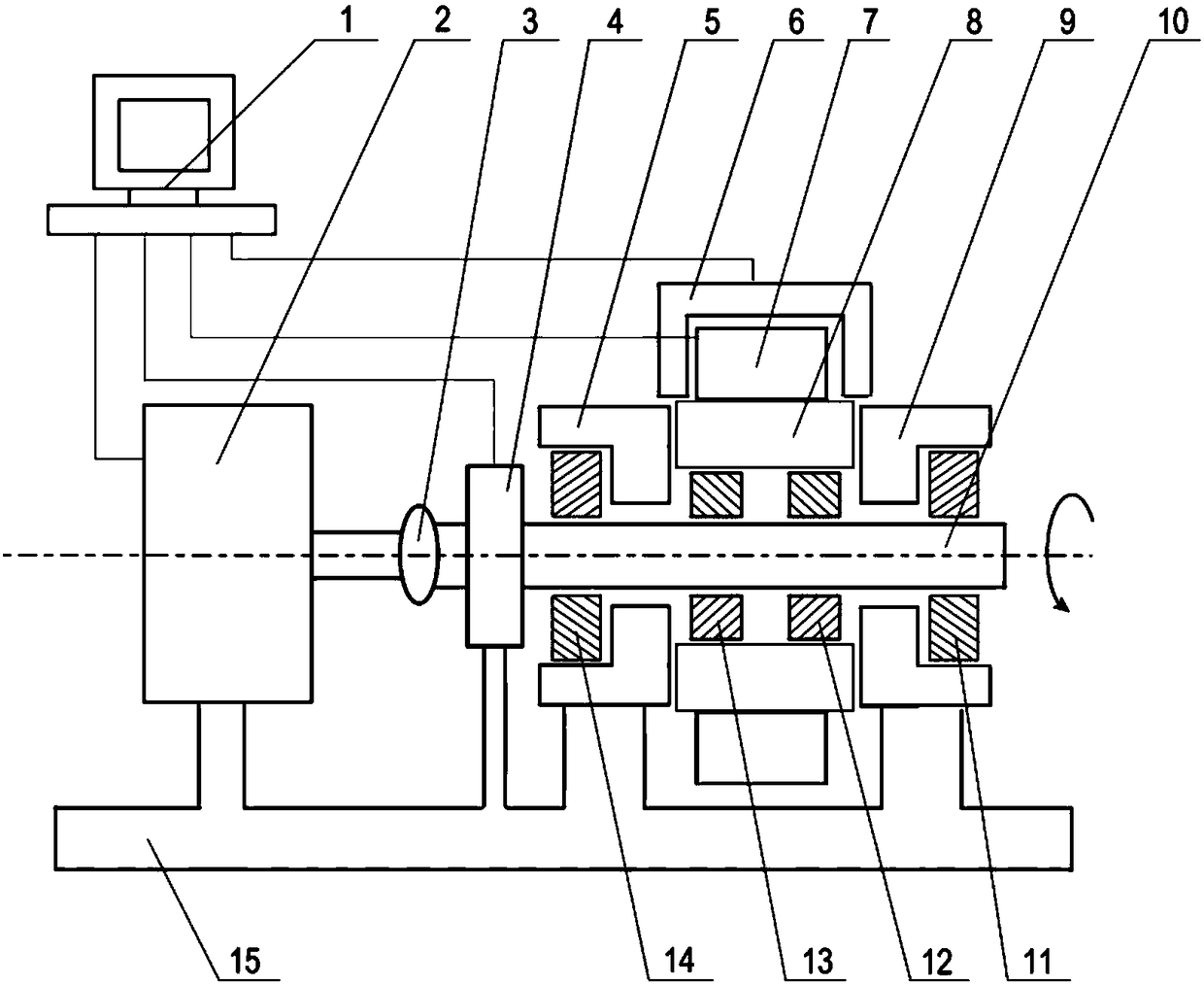

[0038] A rolling bearing fatigue life test system loaded with radial alternating loads driven by a screw is used to measure the fatigue life of rolling bearings under radial alternating loads. Composed of multiple rolling elements between the inner and outer rings, the system includes,

[0039] work platform (15),

[0040] Drive motor (2), is connected on the working platform (15),

[0041] The rotating shaft 10 is connected to the driving motor 2, preferably through a coupling 3, and the rotating shaft 10 is provided with a torque meter 4.

[0042] The fixed fixture A5 and the fixed fixture B9 are connected on the working platform 15. The fixed fixture A5 holds the test rolling bearing A14, and the fixed fixture B9 holds the test rolling bearing B11. The test rolling bearing A 14 and the test rolling bearing B11 together to the role of supporting the rotating shaft 10,

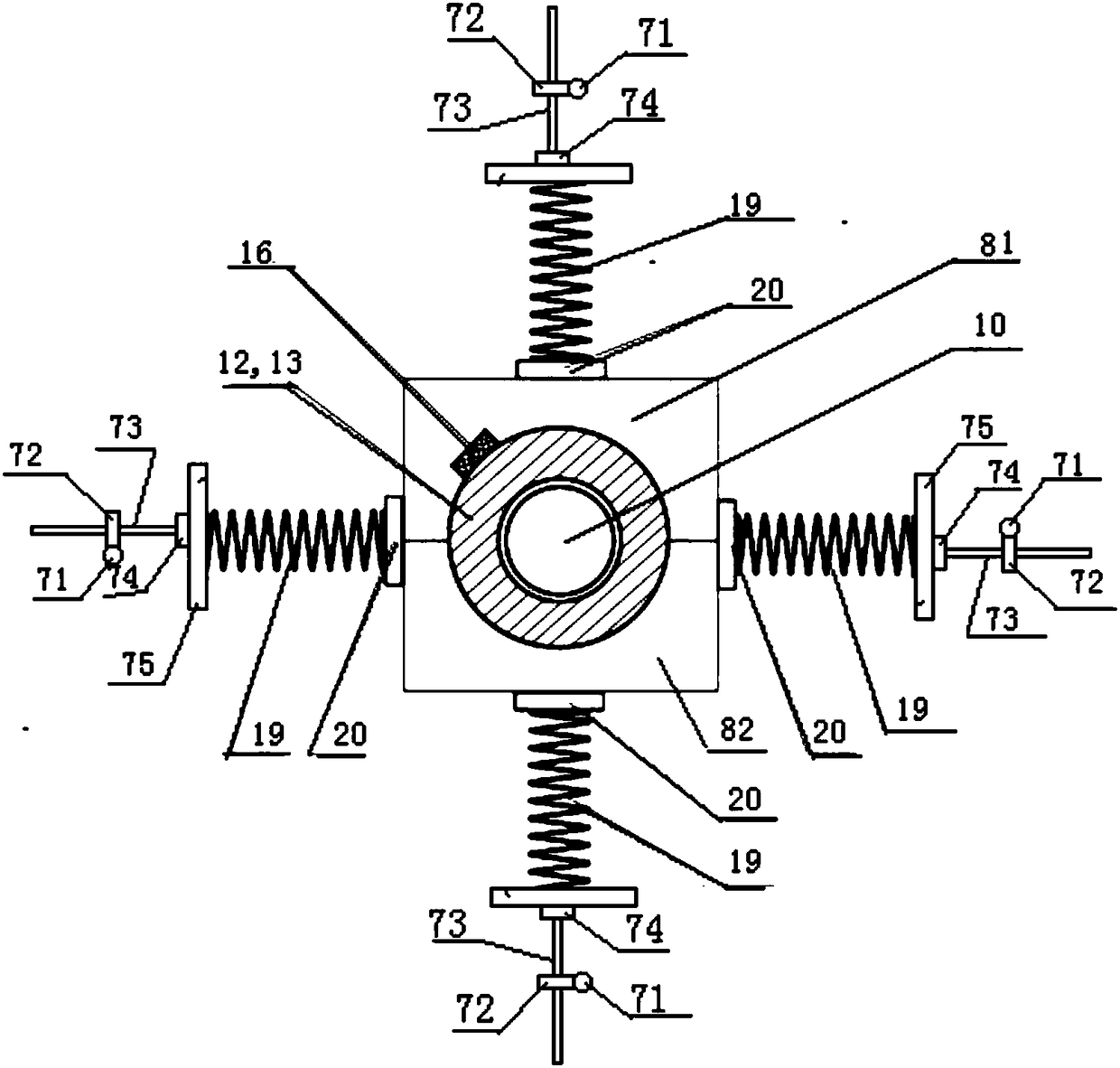

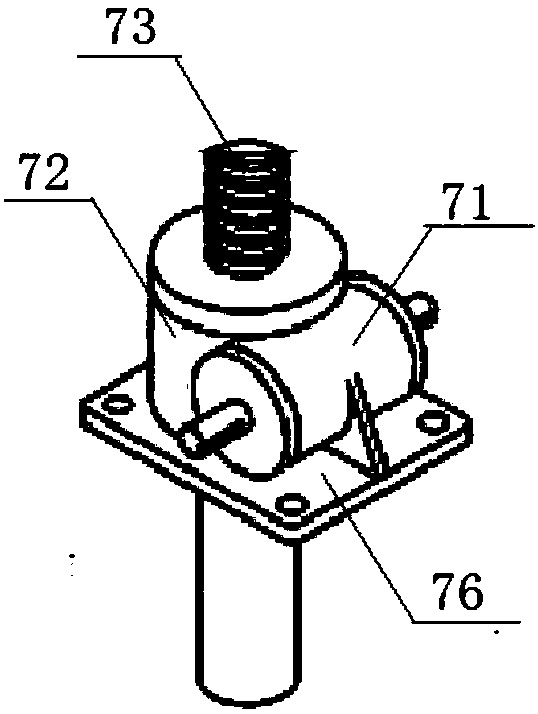

[0043] The movable fixture (8) is located between the fixed fixture A (5) and the fixed fixture B (9), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com